Positive displacement dispenser and method for dispensing discrete amounts of liquid

A dispenser, liquid technology, applied in the direction of the surface coating liquid device, measuring capacity, liquid injection device, etc., can solve the problem of affecting the deposition pattern, leaking liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

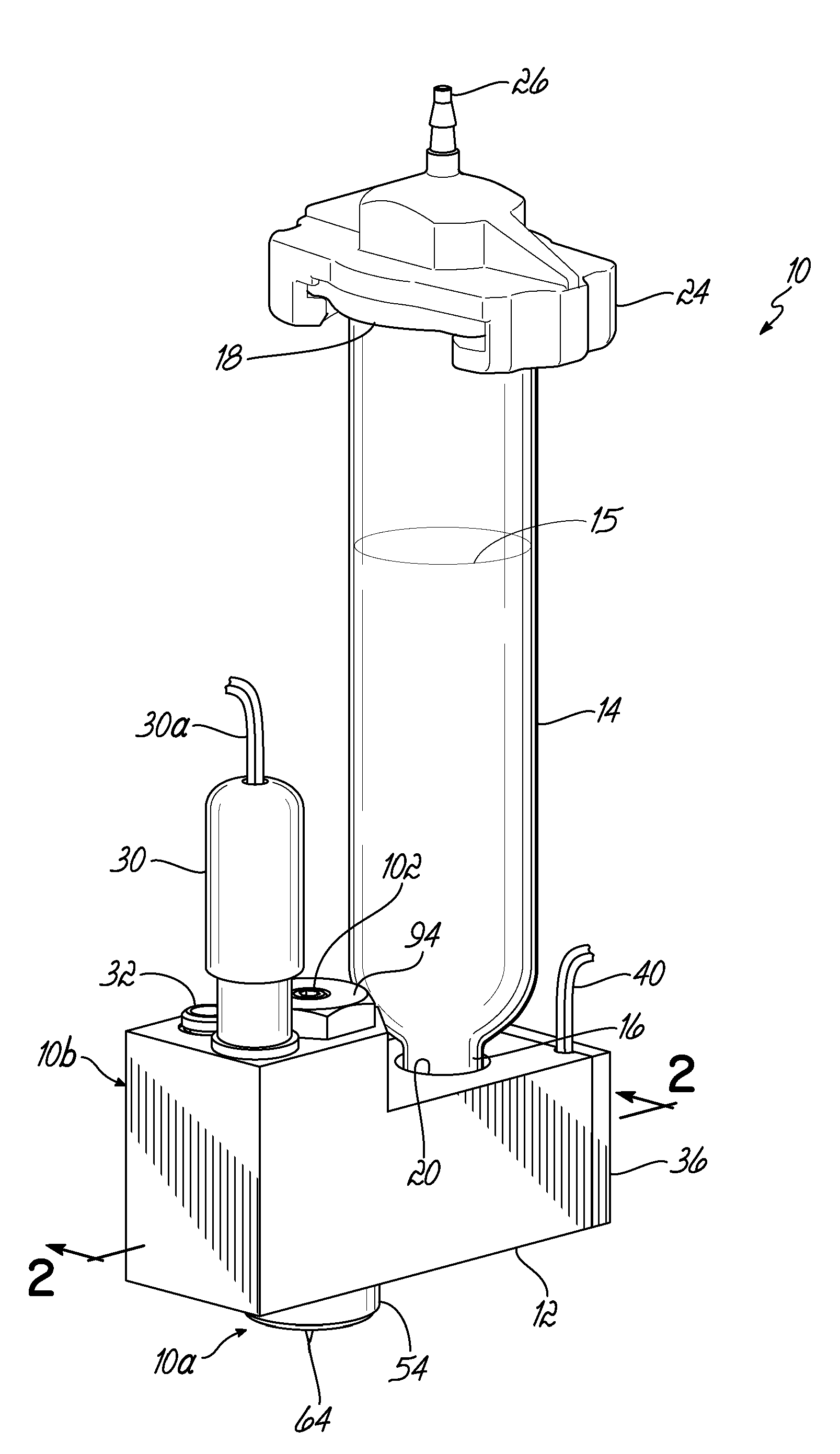

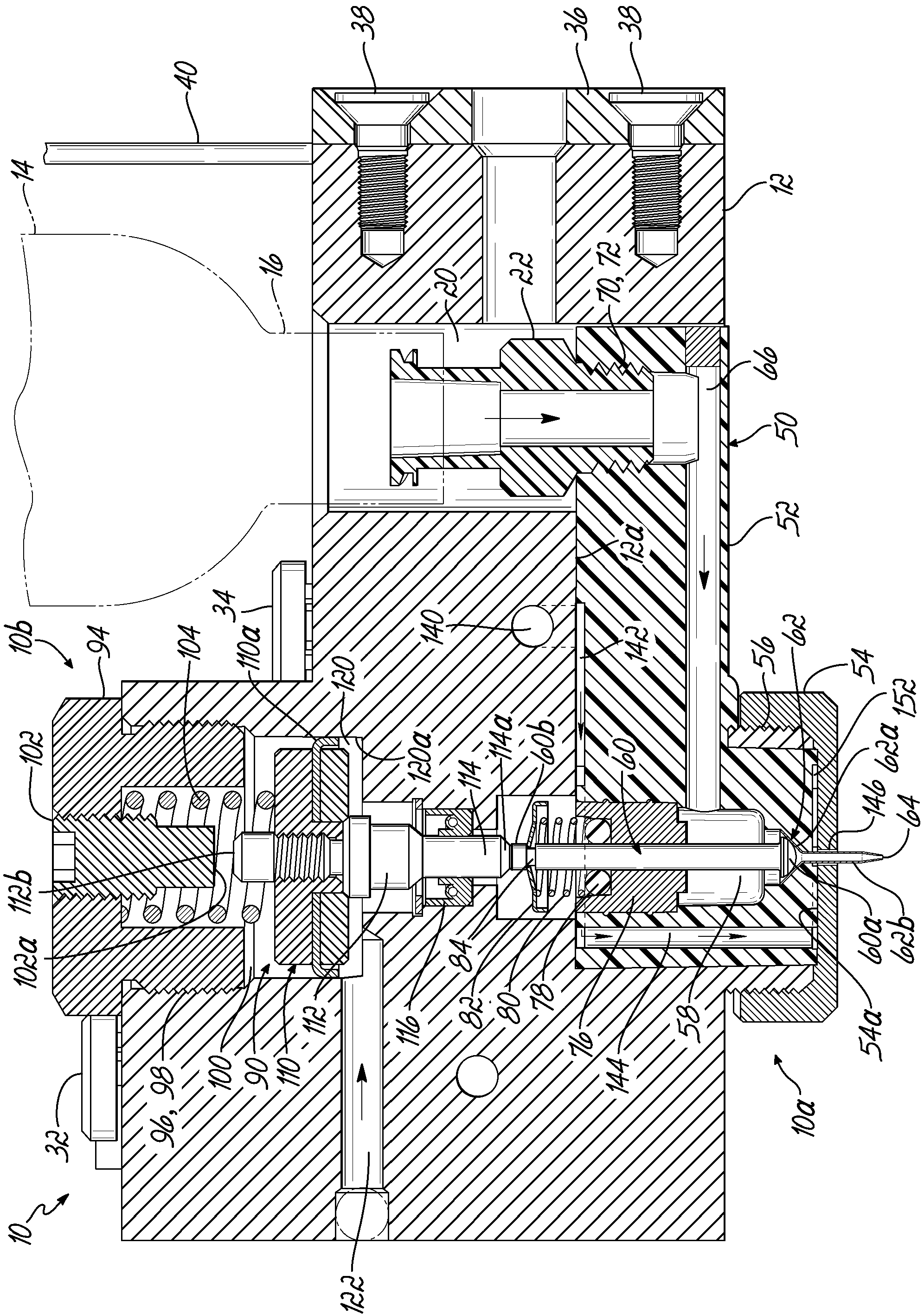

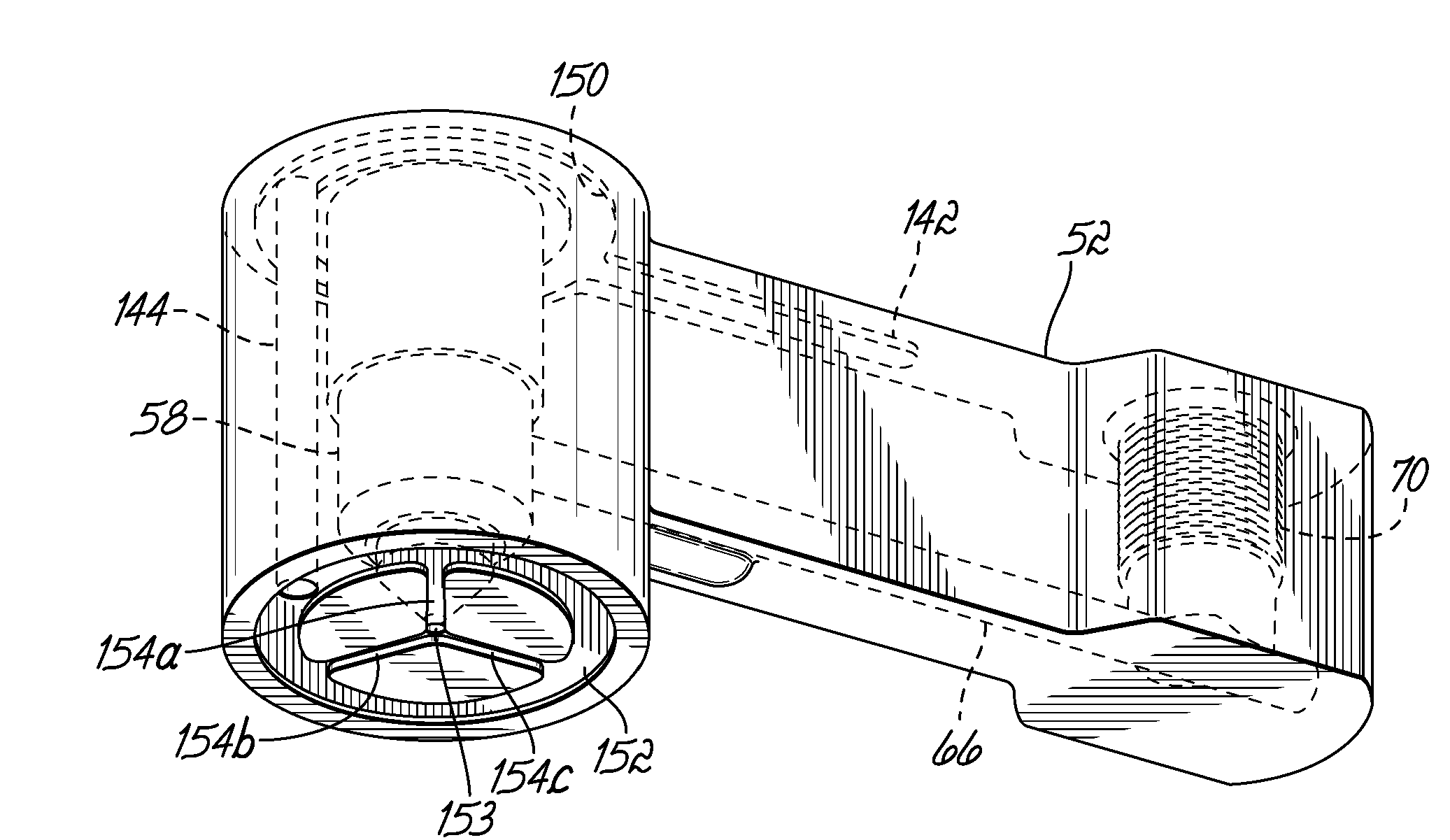

[0025] figure 1 and figure 2A dispenser 10 constructed in accordance with one example embodiment is illustrated. It should be noted that various spatial and directional references, such as horizontal, vertical, up, down, etc., are used to describe the drawings and are done for convenience and clarity of description only. It will be appreciated that the dispenser 10 can be used in a variety of orientations and can dispense a variety of liquids with a wide range of viscosities, such as alcohol, which is less viscous than water, and epoxy, which is much more viscous than water. The dispenser 10 generally includes a dispensing portion 10a and an actuator portion 10b, and these portions are associated with a dispenser body 12 in the illustrated embodiment. The dispenser 10 also includes a container or reservoir 14 of liquid 15 to be dispensed. Container 14 is removably coupled to dispenser body 12 . Container 14 includes a first end 16 and a second end 18 . The first end 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com