Free falling type tobacco leaf sorting device and tobacco leaf sorting method

A sorting device and tobacco leaf technology, applied in sorting and other directions, can solve the problems of huge personnel allocation, stable personnel constraints, large labor consumption, etc., and achieve the effects of simple principle, reduced labor intensity and time, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

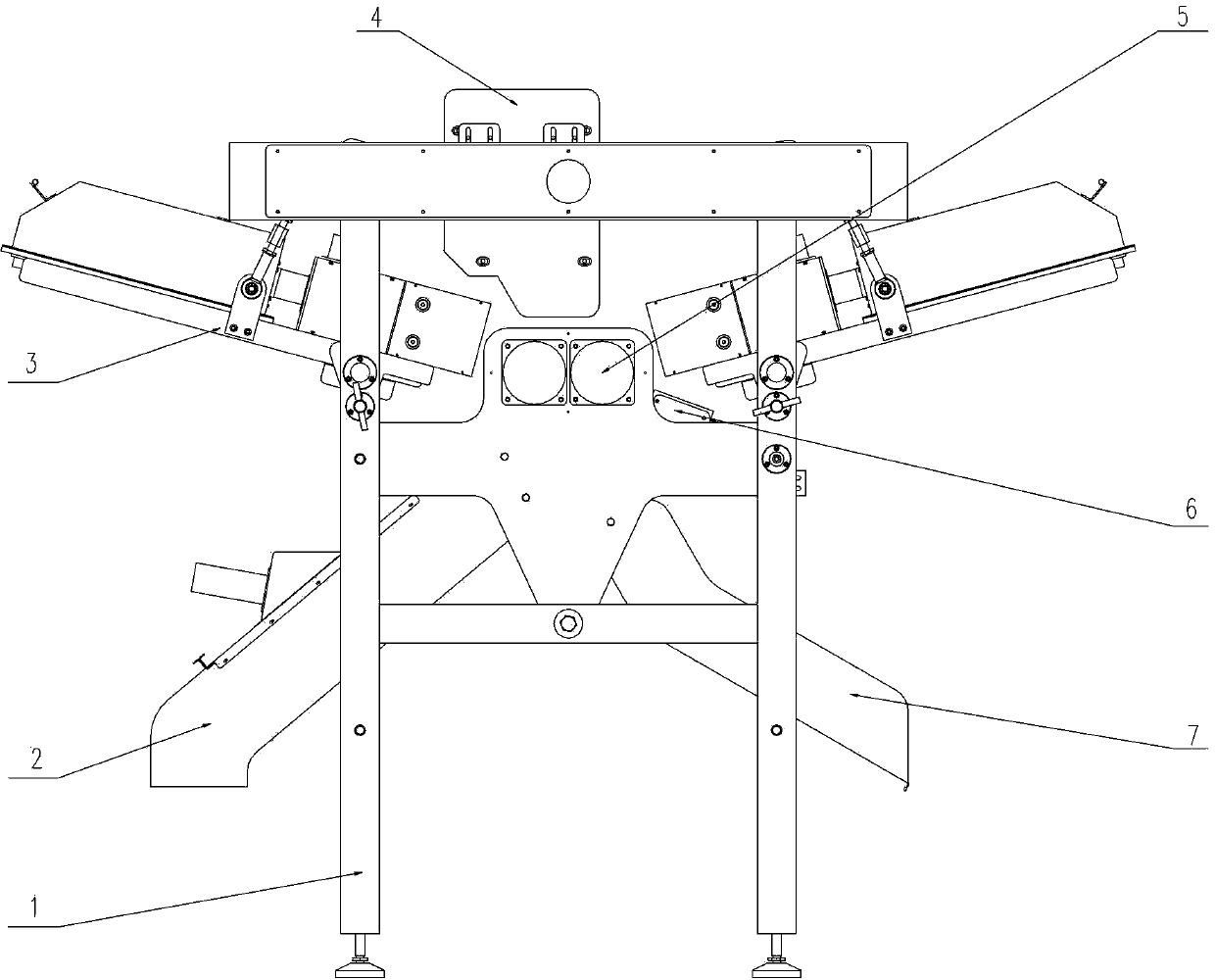

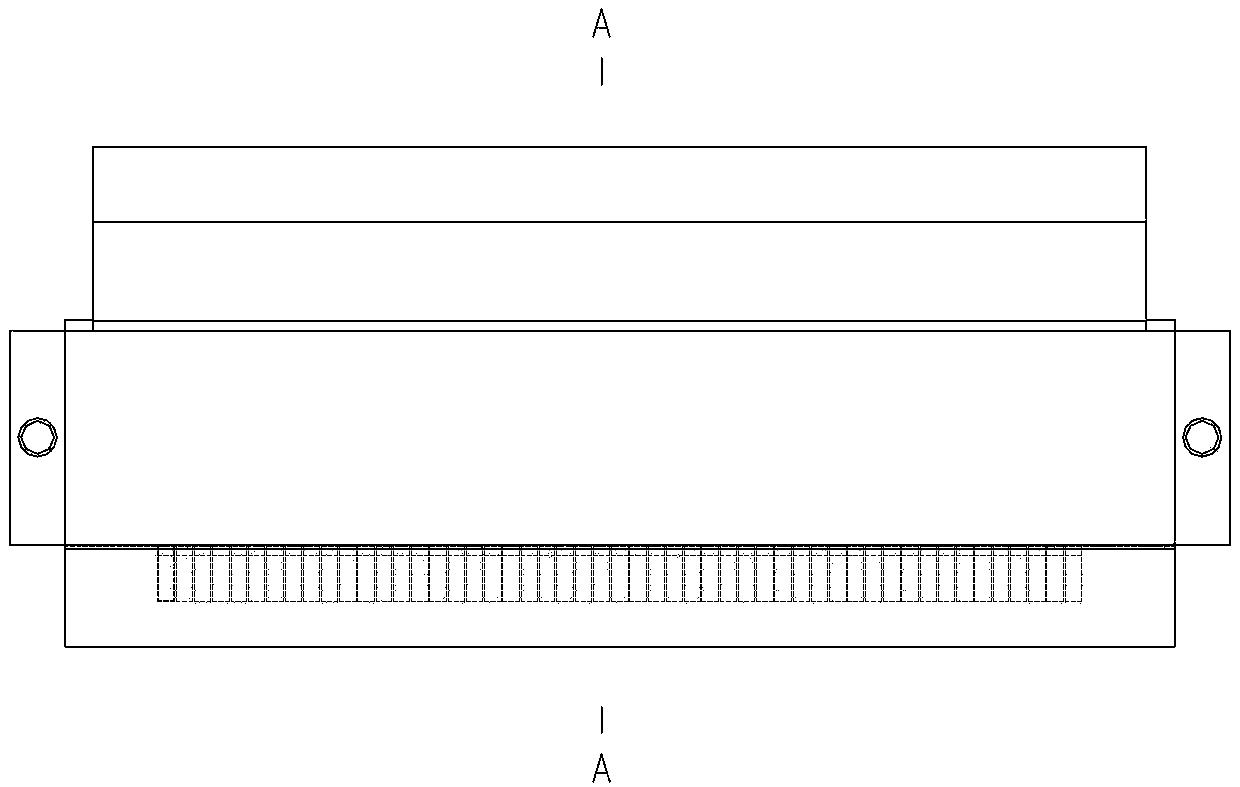

[0028] Such as Figure 1-5 , a free-falling tobacco leaf sorting device, characterized in that it includes a conveying device, a frame 1, a chute 4, a rejection chute 2, an acceptance chute 8, a camera, a background roller 6, an image recognition module and Blowing and rejecting device; the chute 4, the rejecting chute 2, the accepting chute 8 and the camera device are all installed on the frame 1;

[0029] The conveying device is connected to the entrance of the chute 4, and the background roller 6 is arranged below the exit of the chute 4; It is arranged below the background roller 6, and the reject chute 2 is arranged on both sides of the side below the background roller 6;

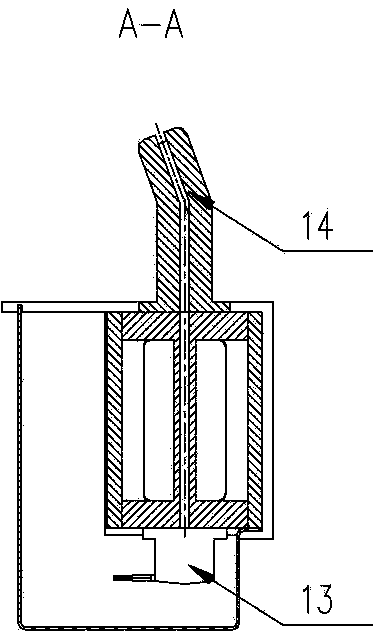

[0030] The rejecting device includes a blowing nozzle 14 and a solenoid valve 13 that controls the air passage of the blowing nozzle 14. The solenoid valve 13 communicates with the air source; ; When the blowing nozzle 14 is blowing, the tobacco leaves are blown into the rejecting trough 2; when the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap