Current control method during necking detection of molten electrode arc welding

A melting electrode, arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of instability, unable to suppress sputtering, unable to suppress welding state, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

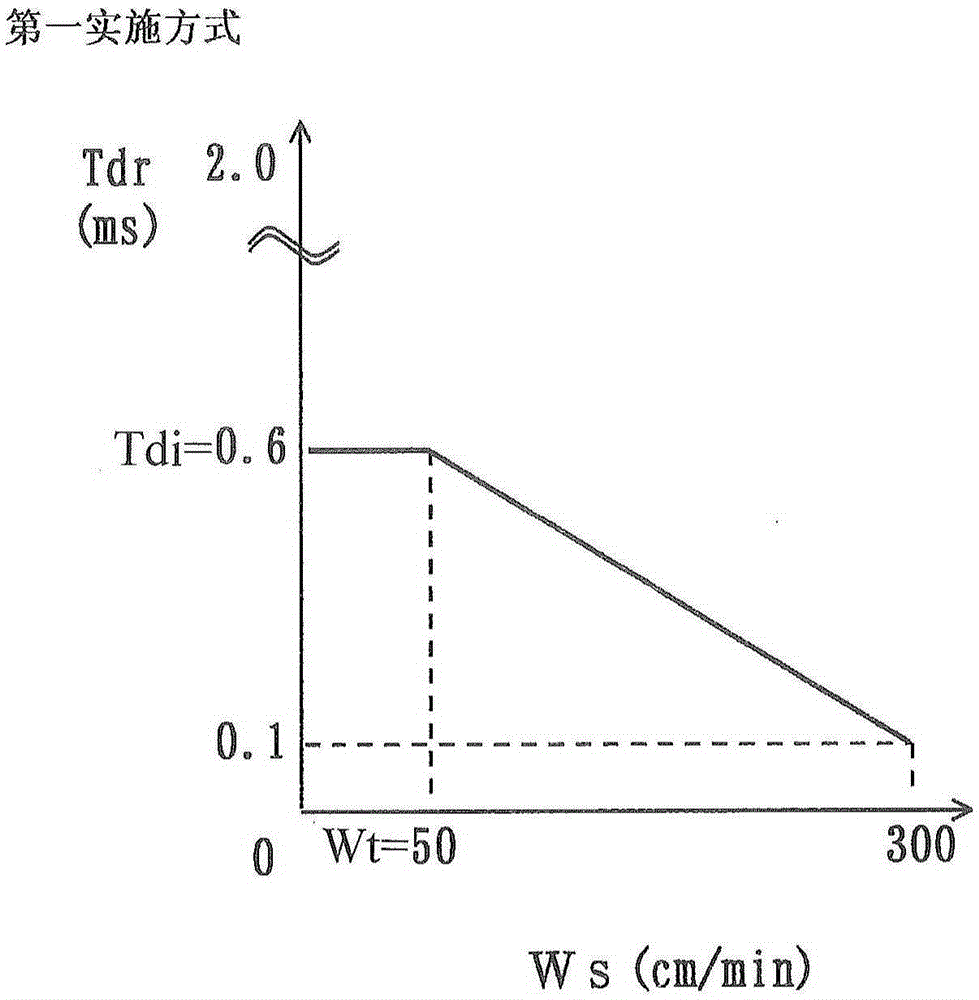

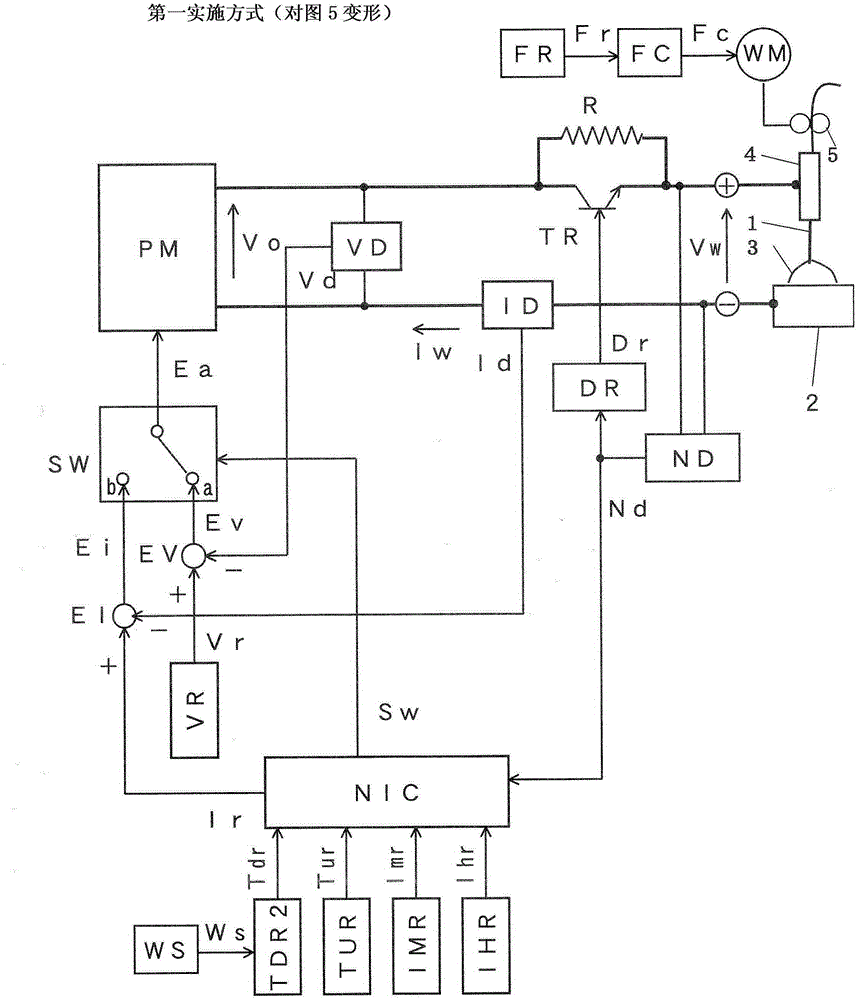

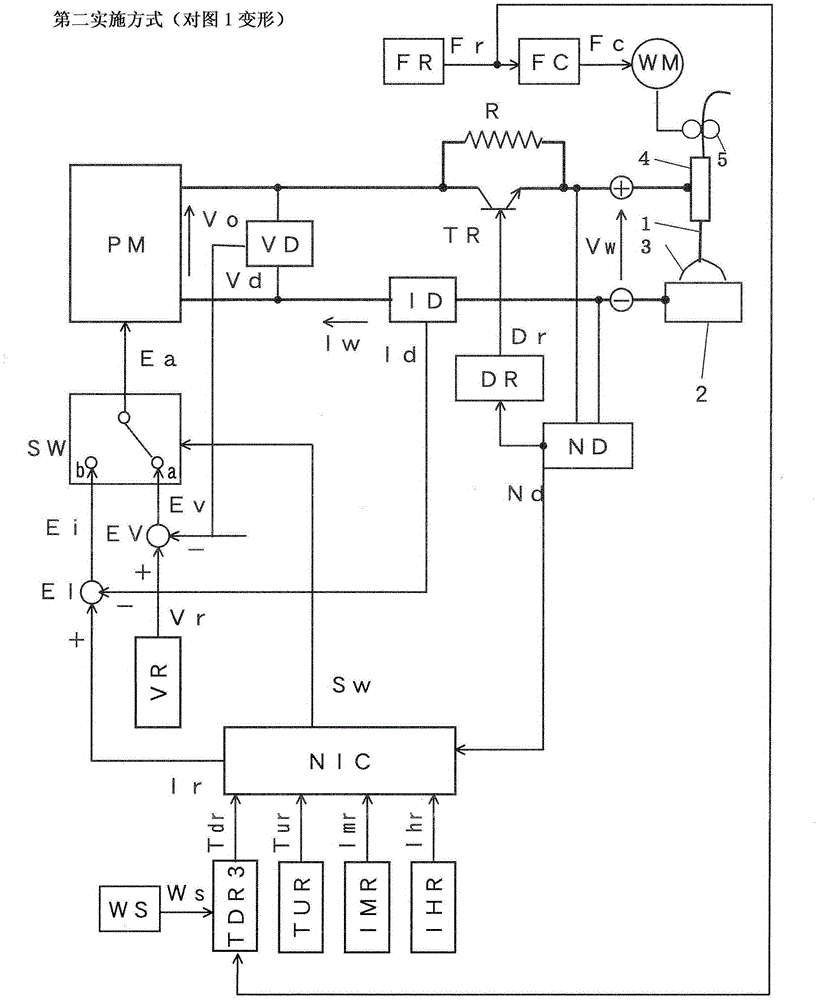

[0099] figure 1 It is a block diagram of a welding power source for carrying out the current control method at the time of constriction detection in metal arc welding according to the first embodiment of the present invention. The figure is in the above Figure 5 Increase the welding speed setting circuit WS, will Figure 5 The delay period setting circuit TDR is replaced by the second delay period setting circuit TDR2. In this figure, for Figure 5 For the same boxes, the same symbols are attached and their descriptions are omitted. Hereinafter, the different blocks will be described with reference to this figure.

[0100]The welding speed setting circuit WS outputs a predetermined welding speed setting signal Ws. In the welding apparatus using a robot, since the welding speed is set in a robot control device (not shown), information related to the welding speed is sent from the robot control device to the welding speed setting circuit WS. Then, this welding speed sett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com