Arc welding device and arc welding system

An arc welding and arc technology, applied in the field of arc welding devices and arc welding systems, can solve the problems of lack of heat input, sputtering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

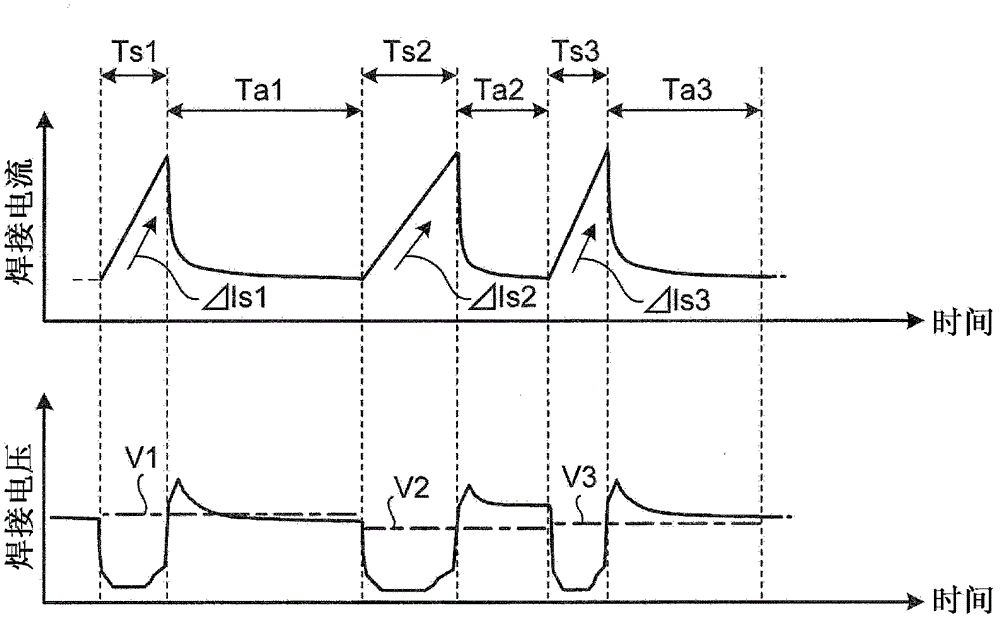

[0014] An arc welding apparatus according to one embodiment performs welding while repeatedly generating a short-circuit state and an arc state between a consumable electrode and a welding member. The arc welding device includes a detection unit and an adjustment unit. The detection unit detects at least one of the duration of the current short circuit and the duration of the current arc. The adjustment unit adjusts the increase rate of the short-circuit current in the next short-circuit generation period according to at least one of the short-circuit generation duration and the arc generation duration detected by the detection unit.

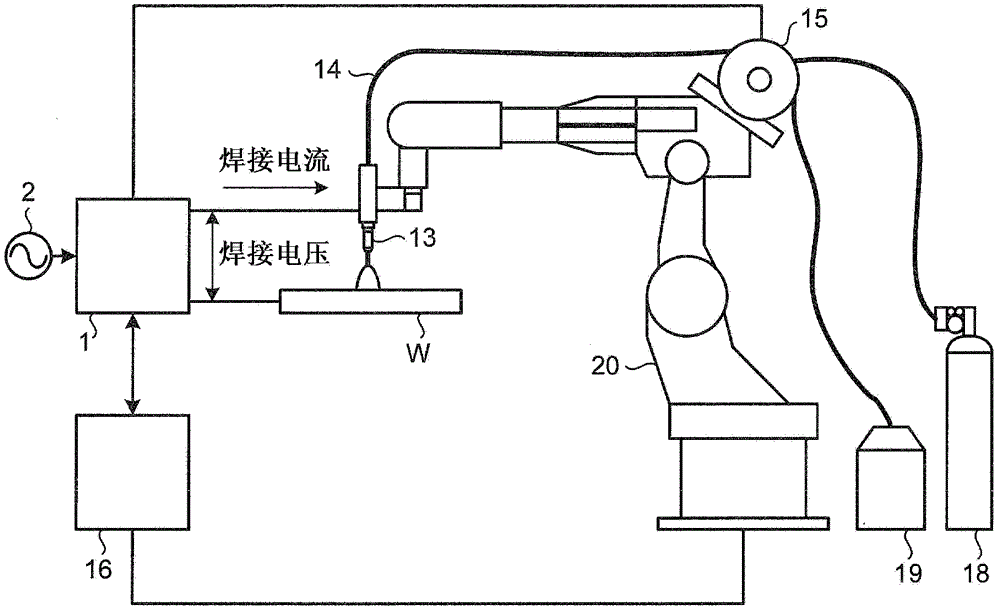

[0015] Embodiments of the arc welding apparatus and the arc welding system disclosed in the present application will be described below based on the drawings.

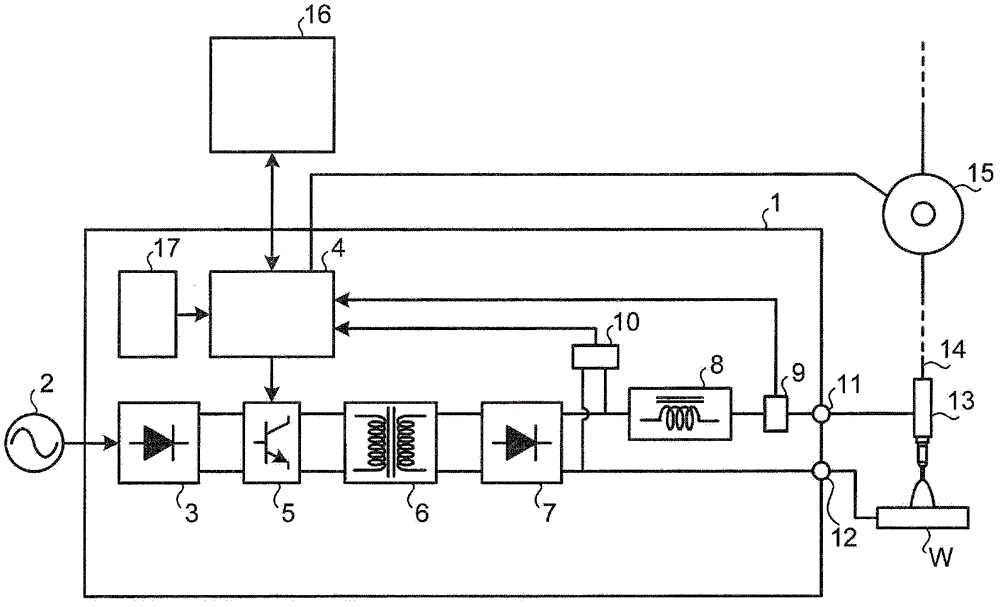

[0016] figure 1 is a configuration diagram of an arc welding apparatus according to one embodiment. The arc welding power source 1 is powered by an AC (alternating current) commercia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com