Steel bar positioning mechanism for mesh welding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

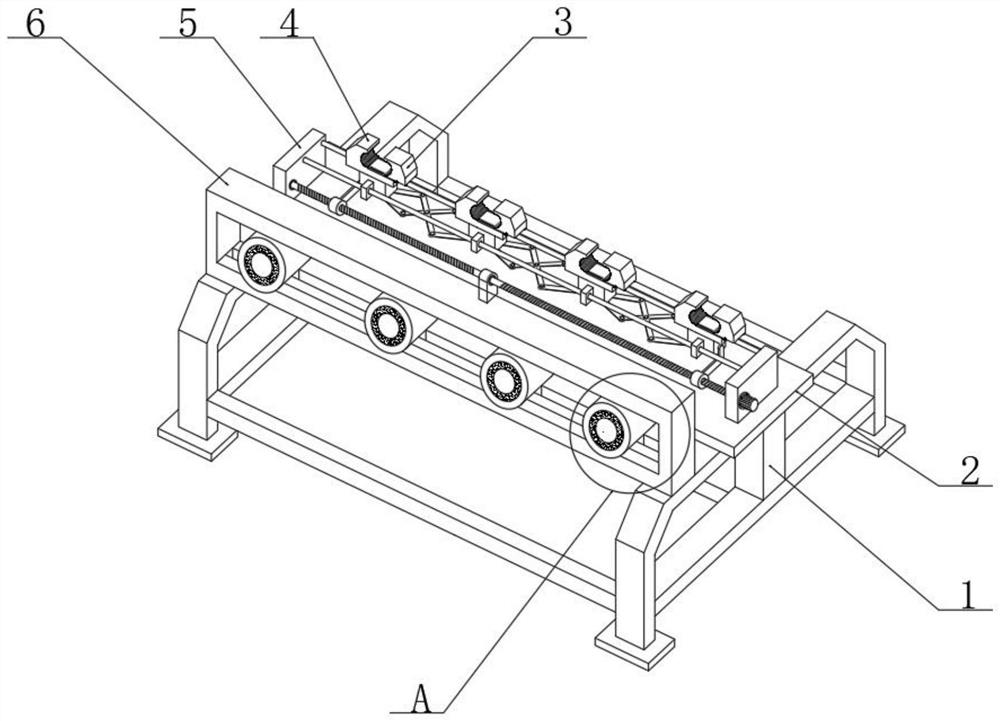

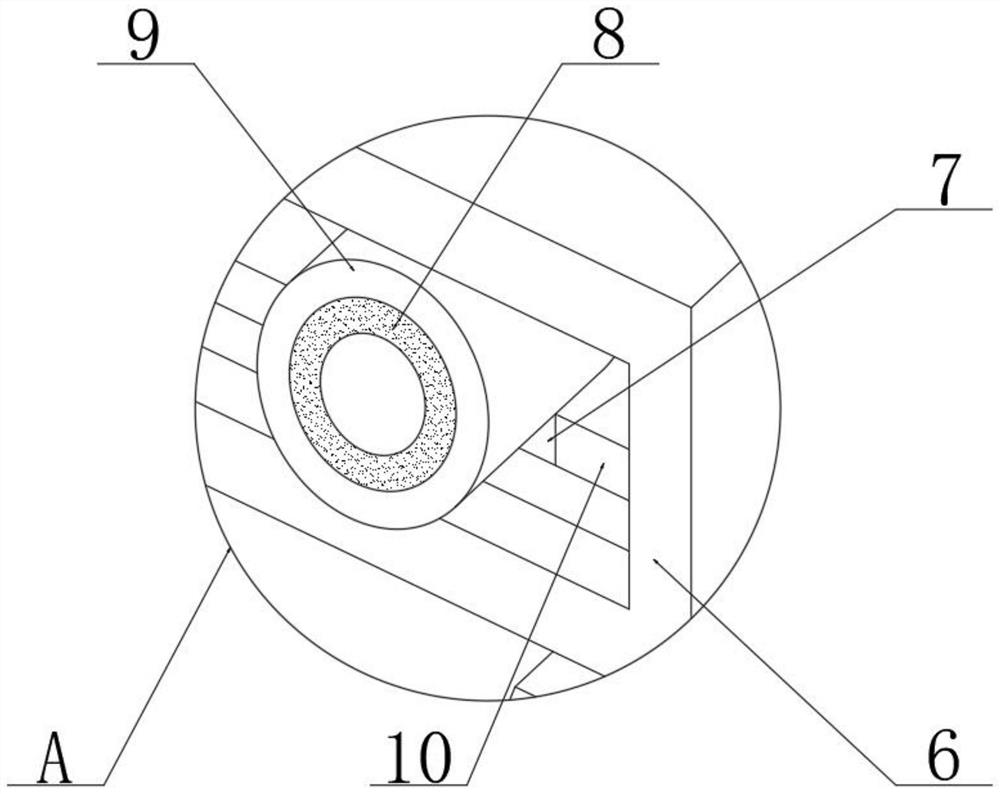

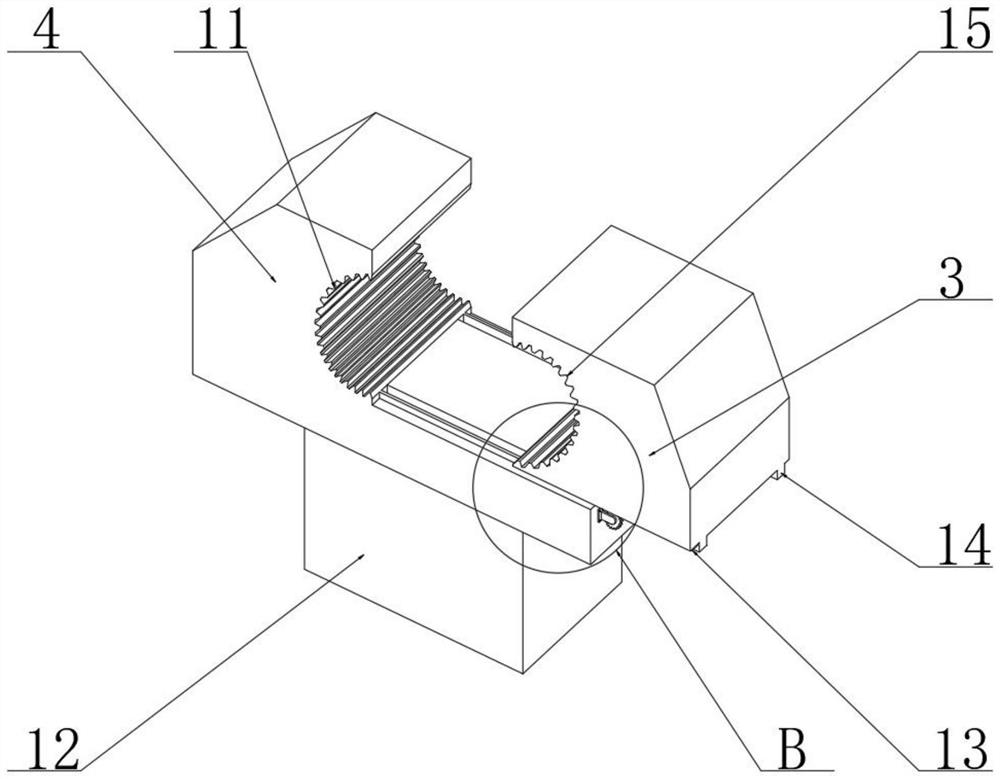

[0022] see Figure 1~5 , in an embodiment of the present invention, a steel bar positioning mechanism for a welding mesh machine includes an underframe 1, a bearing plate 2 is fixed above the underframe 1, and several steel bars with different diameters are arranged above the bearing plate 2. The variable diameter jaw includes a positioning clamp 4, the bottom of the positioning clamp 4 is fixed with a base 12, and a movable clamp 3 slides above one side of the positioning clamp 4, and the positioning clamp 4 and the movable clamp The opposite sides of 3 are respectively provided with a first half-arc groove 11 and a second half-arc groove 15, and the inner sides of the first half-arc groove 11 and the second half-arc groove 15 are provided with anti-slip teeth, which can play an anti-slip effect;

[0023] The opening and closing between the positioning clamp block 4 and the movable clamp block 3 is realized by a driving mechanism. The driving mechanism includes two second sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com