Solar heat-absorbing fin wrapped with copper tube and welding method of solar heat-absorbing fin wrapped with copper tube

A technology of solar heat absorption and welding methods, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of easily damaged surface oxide layer, corrosion resistance of copper pipes, and remaining weld seams, so as to increase heat conduction effect, prevent corrosion, and increase the effect of heat conduction contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

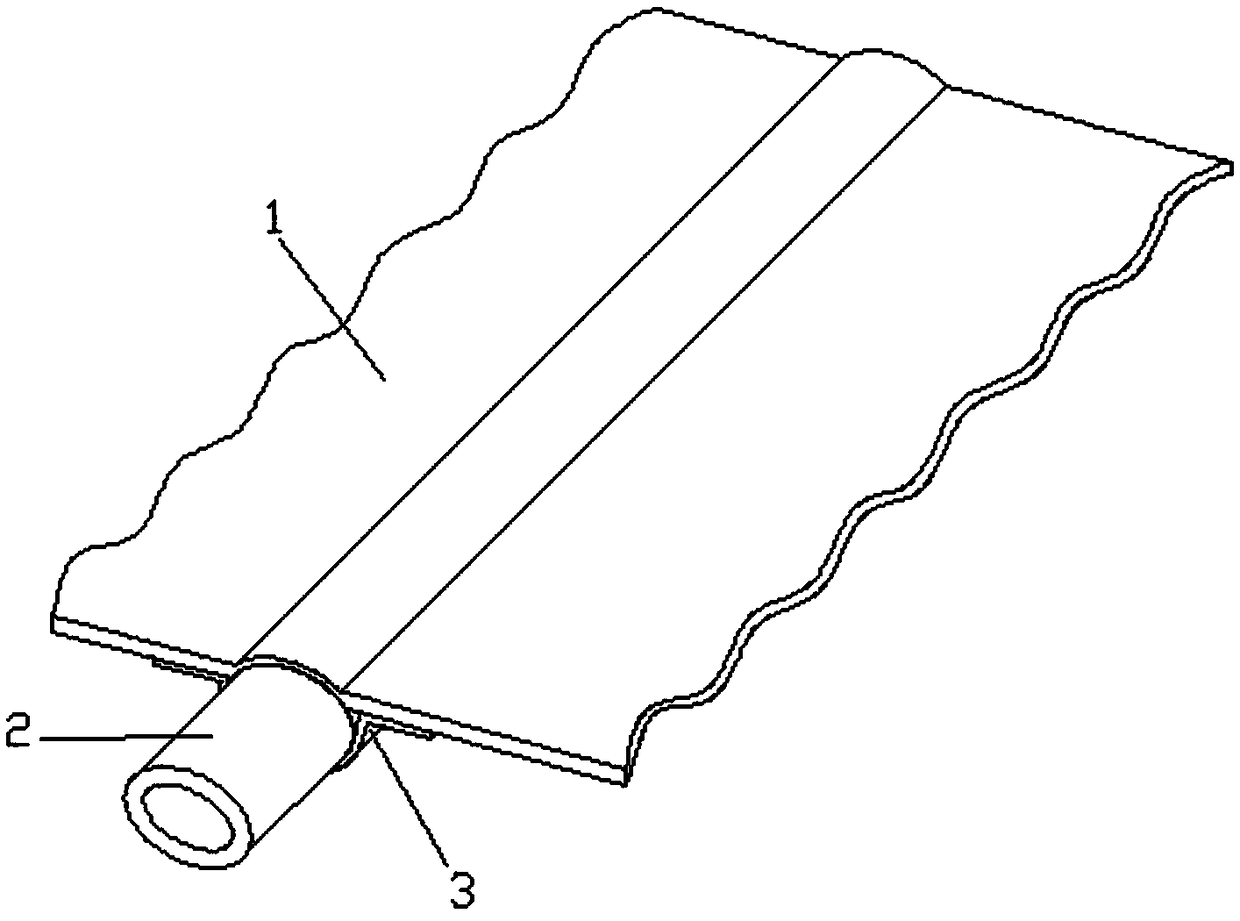

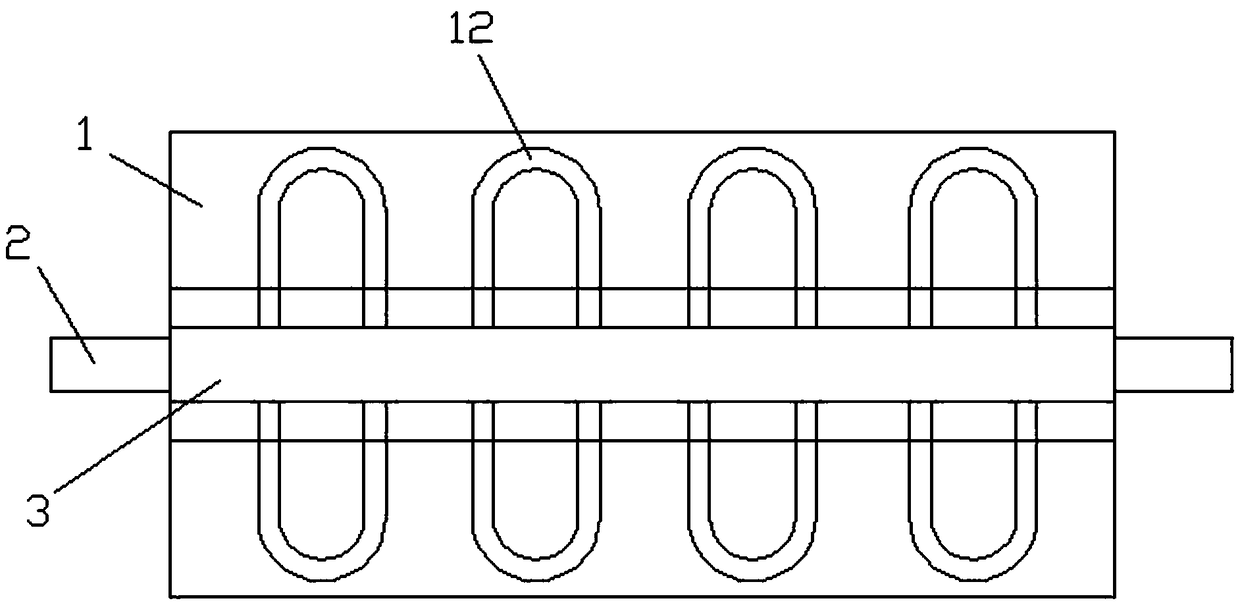

[0024] combine figure 1 , figure 2 Shown; a solar heat-absorbing fin wrapped in copper tube, including aluminum fin 1, copper flow tube 2, aluminum cladding sheet 3, one side surface of aluminum fin 1 is coated with blue base film, aluminum The two sides of the cladding sheet 3 are welded on the central axis along the side of the aluminum fin 1 without blue-plated base film, the copper flow tube 2 is located in the middle of the aluminum fin 1 and the aluminum cladding sheet 3, and the aluminum fin 1 Both sides are sinusoidal linear arc surface structures, and several U-shaped bends 12 are respectively welded at equal distances on both sides of the copper flow tube 2 .

[0025] The U-shaped elbow 12 is closely attached to the lower surface of the aluminum fin 1 .

[0026] A solar heat absorbing fin wrapped with a copper tube, the welding method of which is as follows:

[0027] (1), the aluminum cladding sheet 3 is stamped along the central axis of the length direction by a...

Embodiment 2

[0033] combine figure 1 , figure 2 Shown; a solar heat absorbing fin wrapping copper tube, including aluminum fin 1, copper flow tube 2, aluminum cladding sheet 3, one side surface of aluminum fin 1 is coated with blue base film, aluminum The two sides of the cladding sheet 3 are welded on the central axis along the side of the aluminum fin 1 without blue-plated base film, the copper flow tube 2 is located in the middle of the aluminum fin 1 and the aluminum cladding sheet 3, and the aluminum fin 1 Both sides are sinusoidal linear arc surface structures, and several U-shaped bends 12 are respectively welded at equal distances on both sides of the copper flow tube 2 .

[0034] The U-shaped elbow 12 is closely attached to the lower surface of the aluminum fin 1 .

[0035] A solar heat absorbing fin wrapped with a copper tube, the welding method of which is as follows:

[0036] (1), the aluminum cladding sheet 3 is stamped along the central axis of the length direction by a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com