Arc welding device and arc welding control method

A technology of arc welding and control method, applied in the direction of welding/welding/cutting articles, arc welding equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

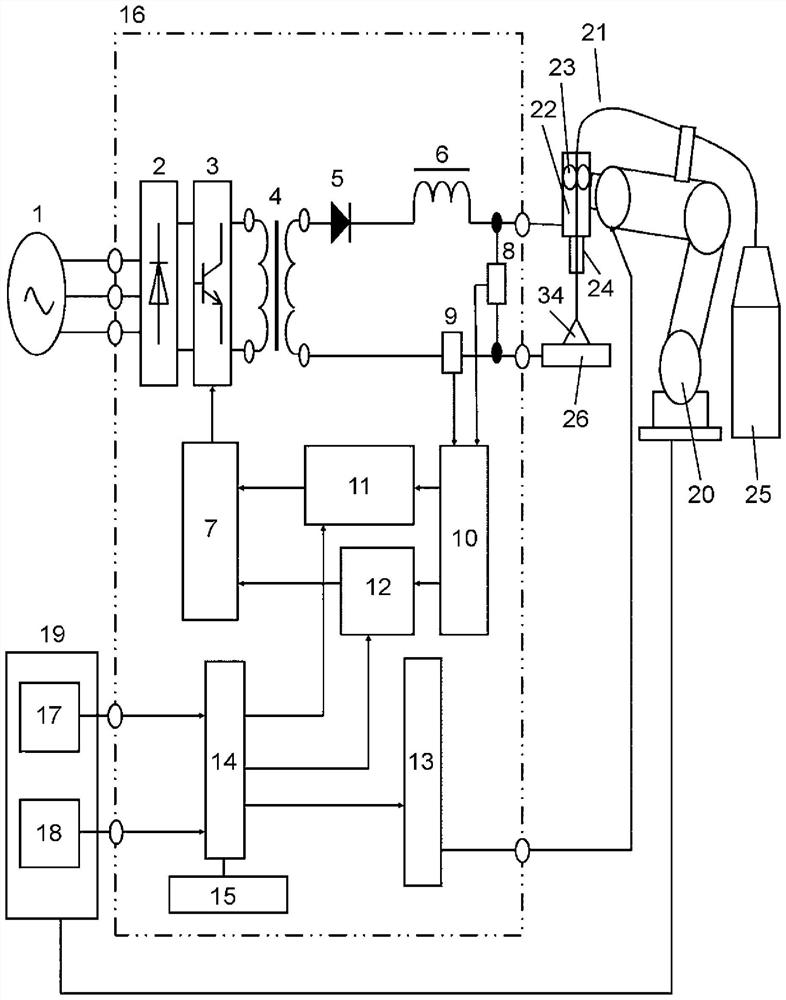

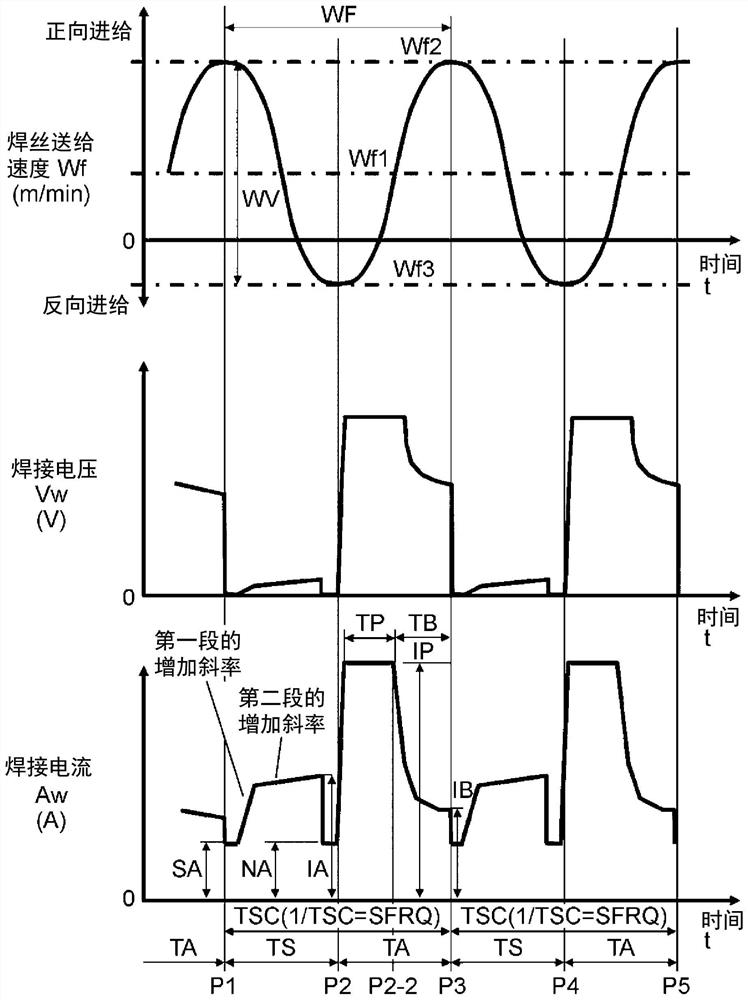

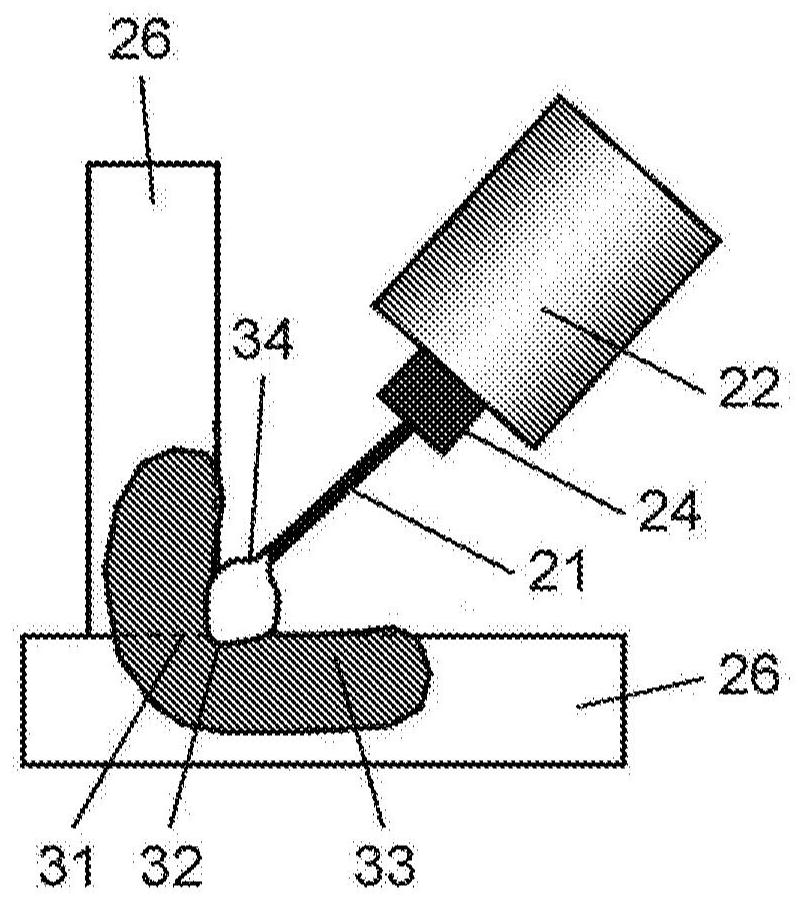

[0050] figure 1 The schematic structure of the arc welding apparatus in this Embodiment 1 is shown in . figure 1 Among them, the welding power supply device 16 is an arc welding device for welding the object to be welded by alternately repeating the short-circuit period TS during which the welding wire 21 and the object to be welded 26 are short-circuited, and the arc period TA during which the short circuit is disconnected and an arc is generated. Rectification part 2, switch part 3, transformer 4, secondary rectification part 5, reactor 6 (also referred to as DCL). The primary rectification unit 2 rectifies the output of the input power source 1 . The switch unit 3 controls the welding output by controlling the output of the primary rectifying unit 2 . The transformer 4 insulates and converts the electric power from the switch unit 3 . The secondary rectification unit 5 rectifies the secondary side output of the transformer 4 . Reactor 6 is connected in series with sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com