Electromagnetic Stirring Assisted Laser Rapid Forming of Nickel-based Alloy Parts

A nickel-based alloy and laser-assisted technology, which is applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., to achieve the effects of inhibiting pores and cracking, improving mechanical properties, and improving organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

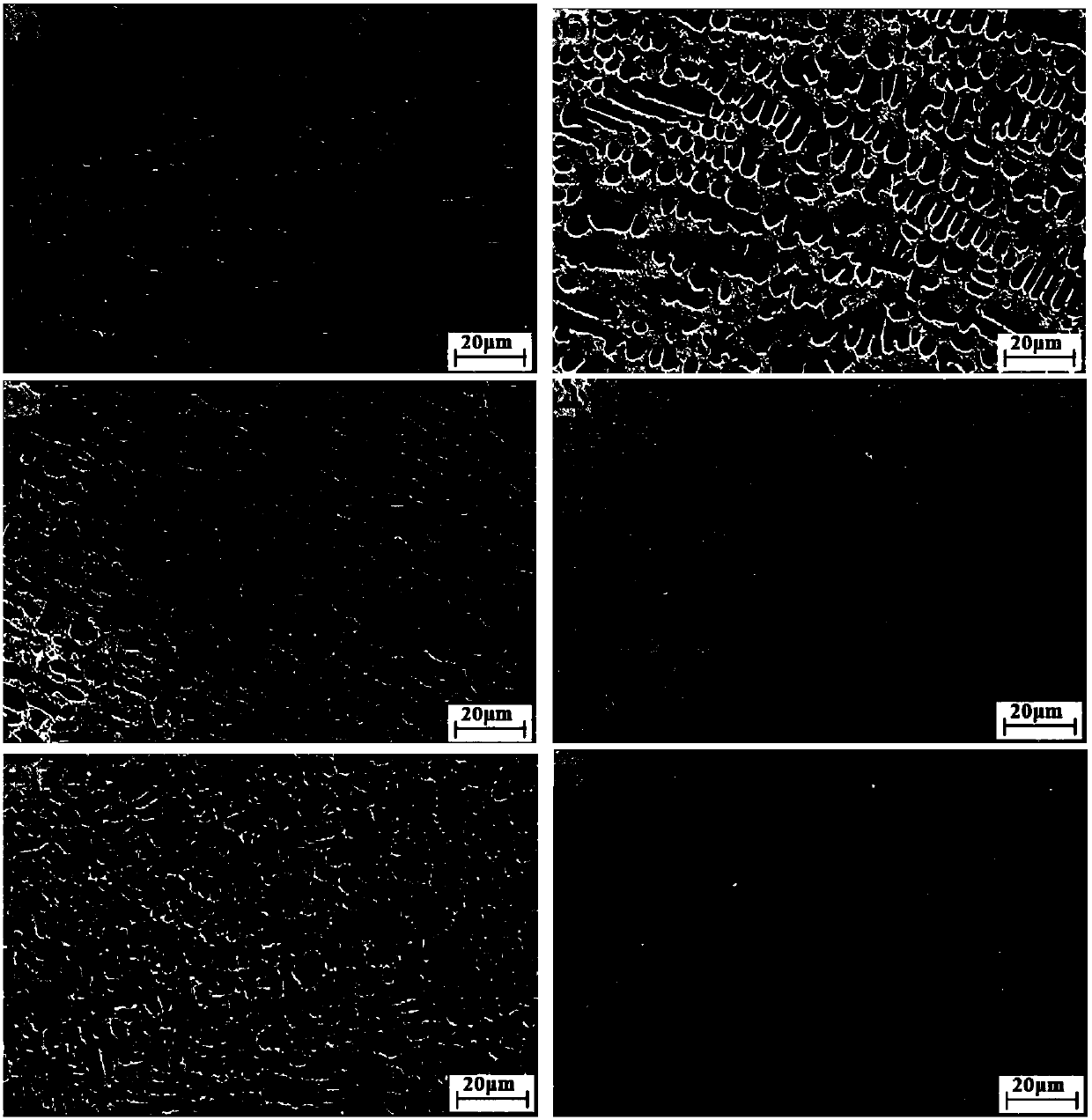

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in combination with specific embodiments.

[0022] Use metallographic sandpaper and acetone solution to polish and clean the surface of the 306 stainless steel substrate, and then place it on the laser rapid prototyping machine tool;

[0023] Connect the coaxial powder feeding nozzle and electromagnetic stirrer to the laser head, and use the numerical control system to move it to the starting processing position;

[0024] will be composed of Ni 65.8 Cr 15 B 3.0 Si 3.5 C 0.7 Fe 12 , The nickel-based alloy with a particle size of 45-180 μm is placed in the barrel of the coaxial powder feeder, and the powder feeder is turned on to start the power supply, and the powder feeding rate is adjusted to 3.5g / min;

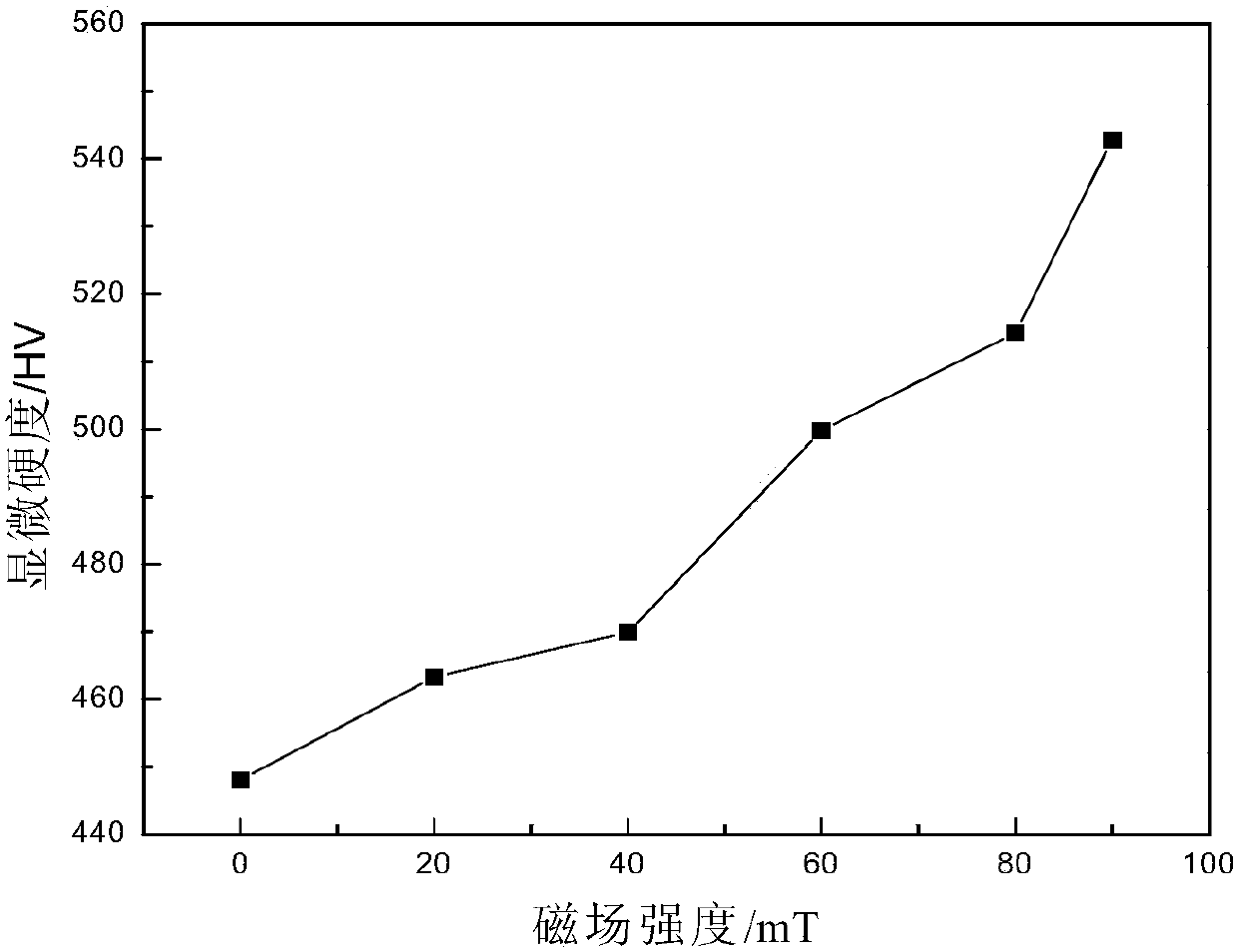

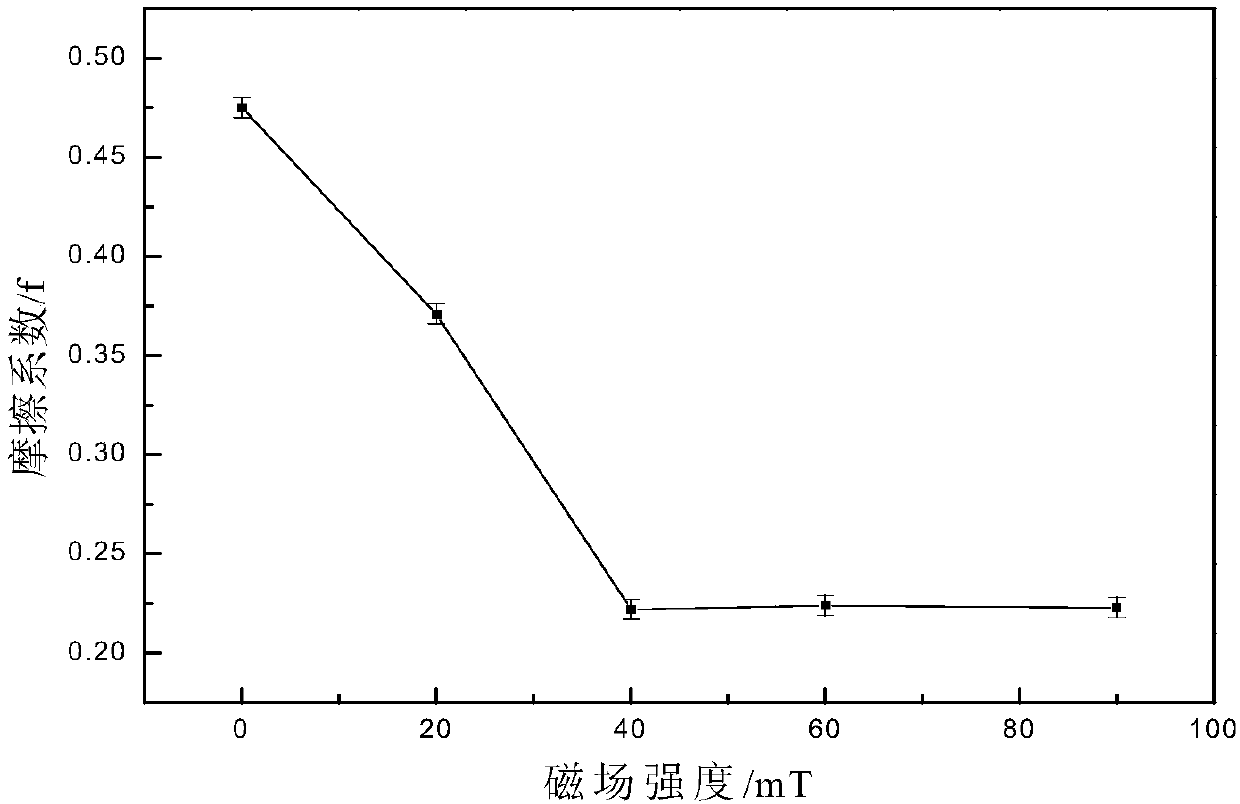

[0025] Turn on the electromagnetic stirrer switch, adjust its frequency to 50Hz, and adjust the magnetic field strength to 10-90mT;

[0026] The start switch of the powder feeder and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com