Clamp for machining molded line of scroll plate

A wire processing and scroll technology, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high equipment processing cost, manufacturing accuracy affecting the working performance of scroll compressors, etc., to ensure quality, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing:

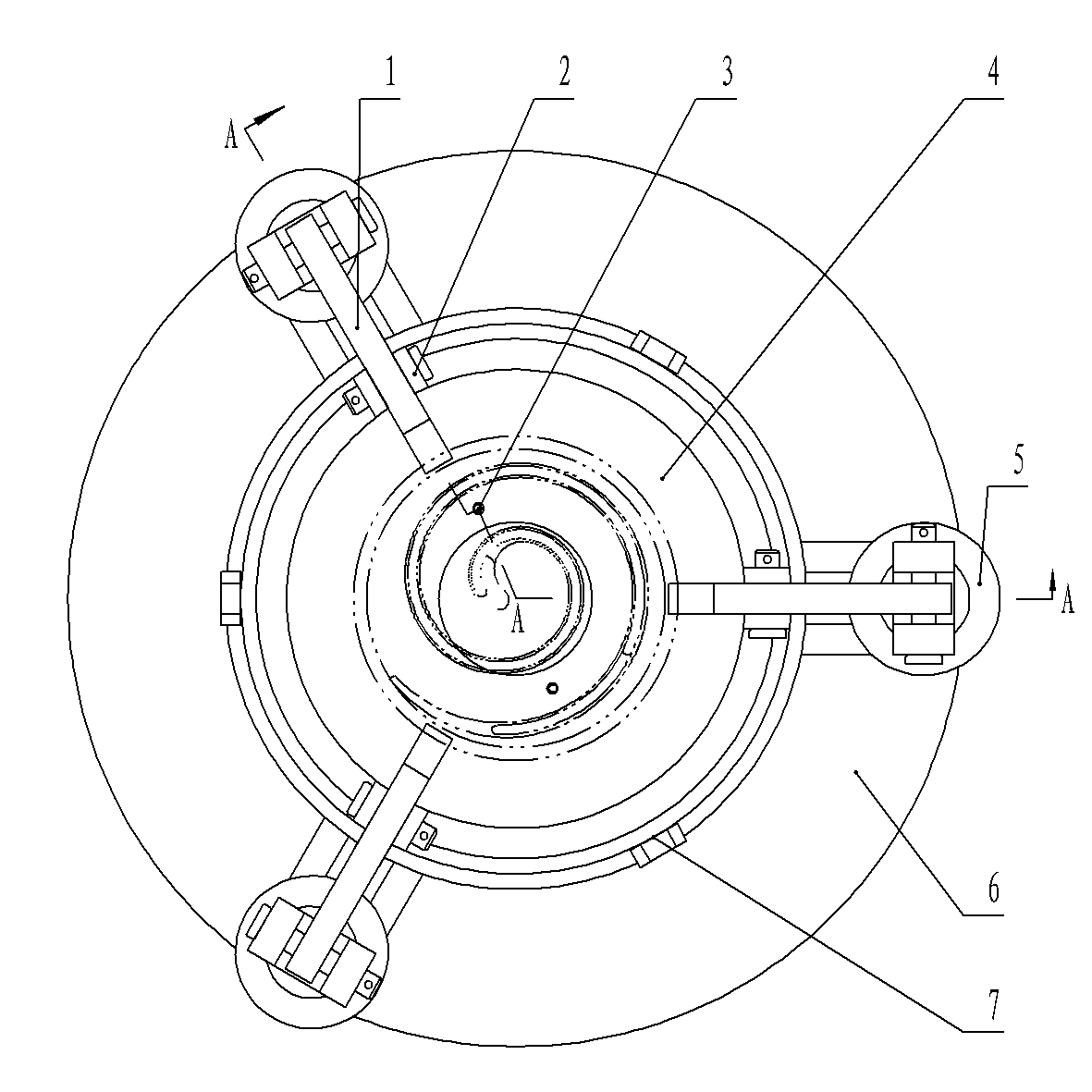

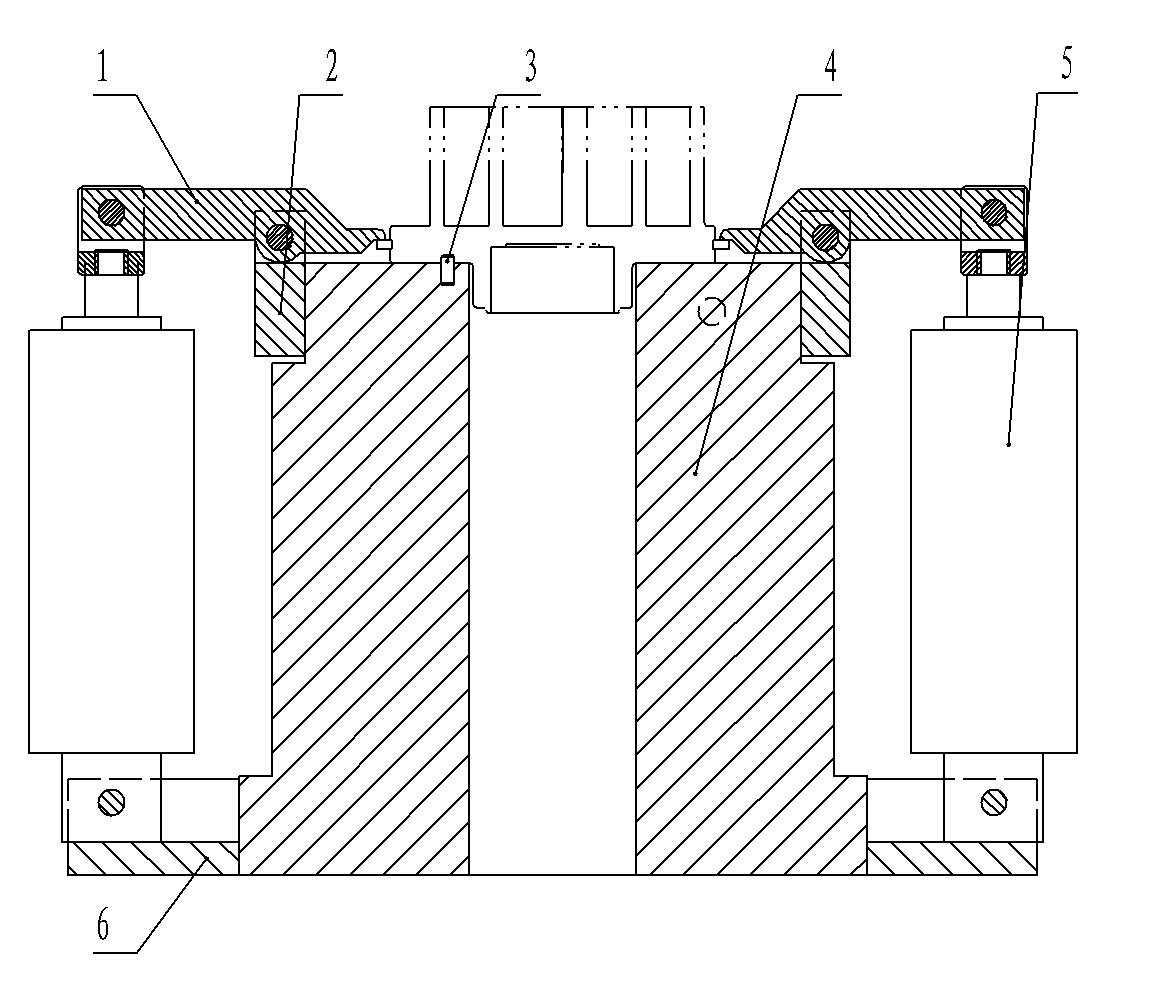

[0010] Such as figure 1 , figure 2 The scroll profile processing jig shown includes a base 4 with a middle hole on the top surface, the bottom of the base 4 is fixedly connected with the lower end plate 6 through interference fit, and three holes are distributed around the middle hole on the top surface of the base 4 . Pressing arm 1, the three pressing arms 1 are connected to the base 4 through hinge shafts, each pressing arm 1 is respectively hinged with a pressing arm driving cylinder 5, and each pressing arm 1 is a protruding part hinged on a connecting ring 2 In the ear plate, the connecting ring 2 is set outside the upper end of the base 4, and the connecting ring 2 is fixedly connected with the base 4 through the bolt 7; two positioning pins 3 are installed on the top surface of the base 4.

[0011] There can also be four pressing arms 1 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com