An internally controlled four-way reversing valve

A four-way reversing valve and spool technology, applied in the field of hydraulic reversing valve, can solve the problems of reducing the working performance of the hydraulic cylinder, hitting the cylinder, etc., and achieve the effect of compensating for leakage and processing errors, and eliminating offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

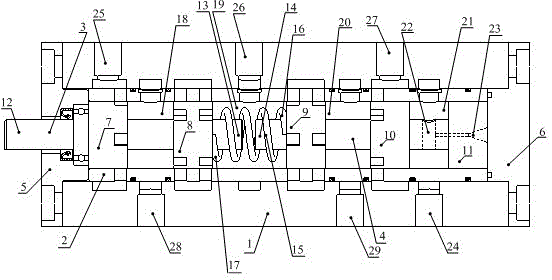

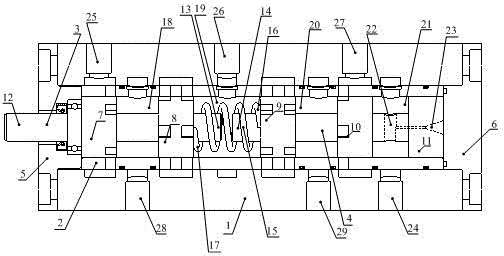

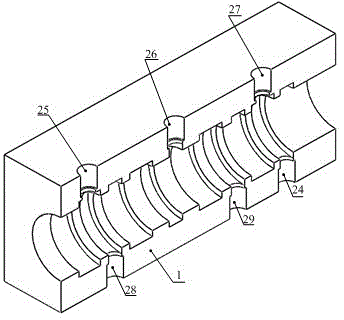

[0023] like figure 1 and figure 2 As shown, the internal control four-way reversing valve of the present invention mainly includes a valve body 1 , a valve sleeve 2 , a first valve core 3 , a second valve core 4 , a first end cover 5 and a second end cover 6 . The first valve core 3 and the second valve core 4 are placed in the cavity of the valve body 1 , and the first end cover 5 and the second end cover 6 are installed together with the valve body 1 at the end faces of the two ends of the valve body 1 respectively.

[0024] like figure 1 , figure 2 , Figure 5 and Figure 6 As shown, the first valve core 3 is provided with a first boss 7 and a second boss 8, and the second valve core 4 is provided with a third boss 9, a fourth boss 10 and a fifth boss 11 , and the first boss 7, the second boss 8, the third boss 9, the fourth boss 10 and the fifth boss 11 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com