Control rod clamping structure and built-in control rod driving mechanism

A clamping structure and control rod technology, applied in the control of nuclear reactions, climate sustainability, reactor fuel elements, etc., can solve the position deviation, pin claws are difficult to accurately grasp the control rod drive shaft, and the control rod drive shaft moves Accuracy adverse effects and other issues, to achieve the effect of accurate claw position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

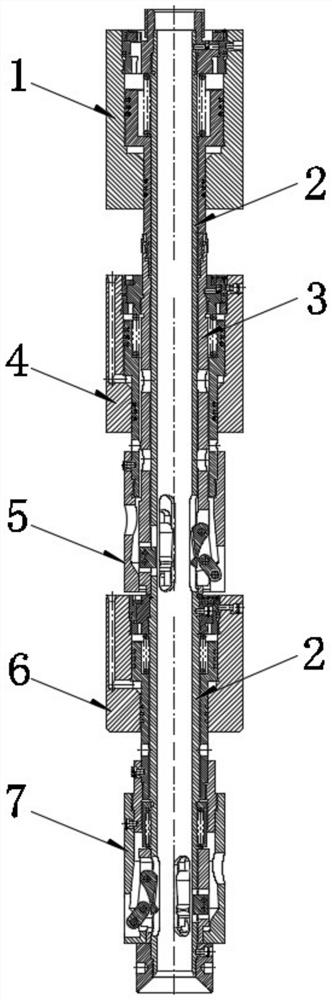

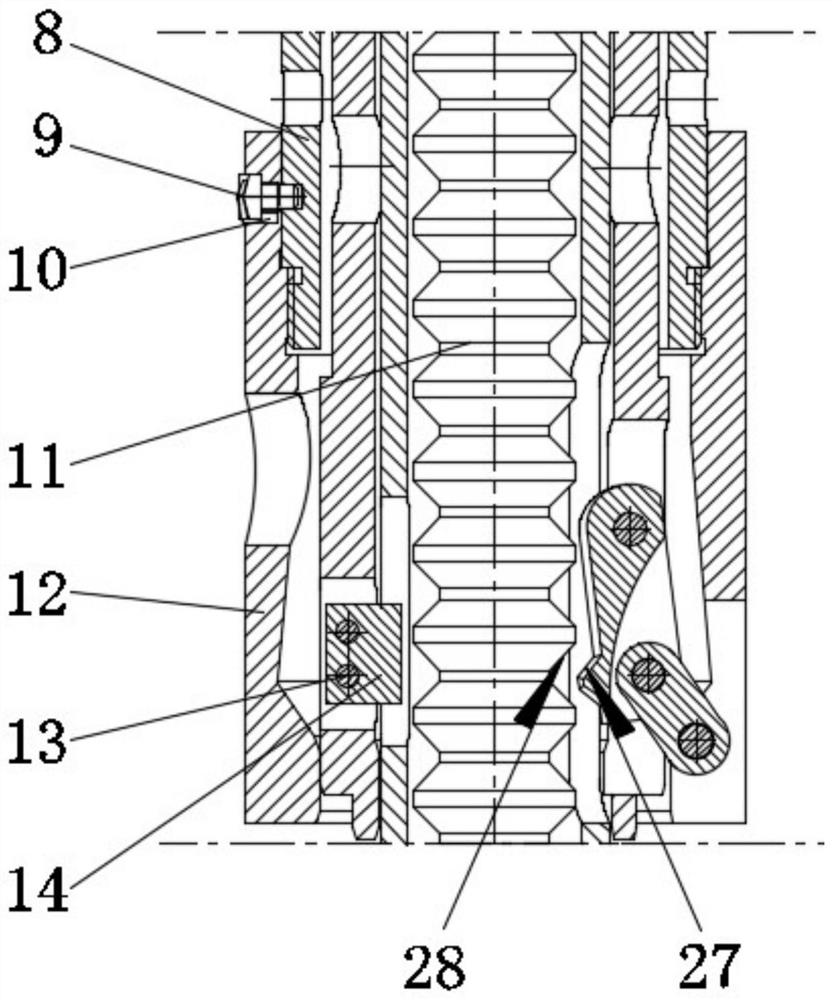

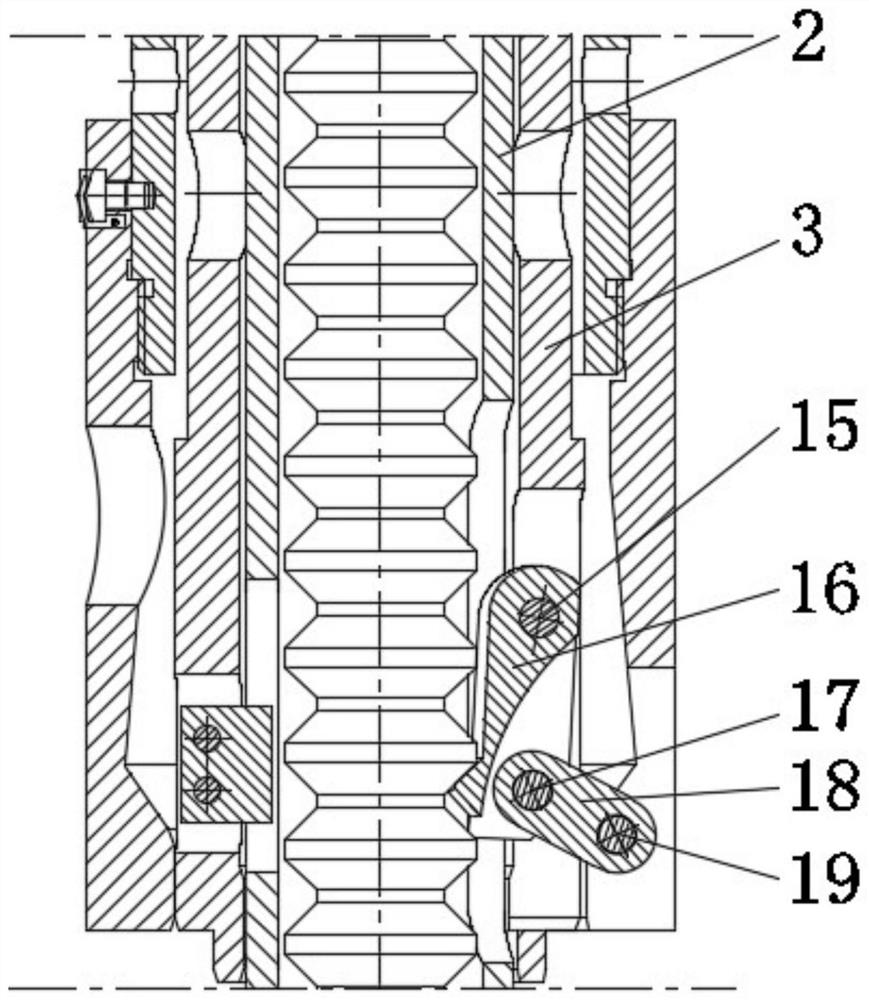

[0038] Such as Figure 1 to Figure 11 As shown, the embodiment of the present invention provides a control rod clamping structure (the embodiment of the present invention is referred to as "structure" for short), and based on this structure, a built-in control rod driving mechanism is provided (the embodiment of the present invention is referred to as "structure" for short). Drive mechanism").

[0039] Such as figure 1 As shown, the structure includes an inner sleeve 2, a positioning mechanism and a claw mechanism. The inner sleeve 2 is used to pass through the shaft holes of several groups of hydraulic cylinders. The inner sleeve 2 is provided with a channel for the control rod drive shaft 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com