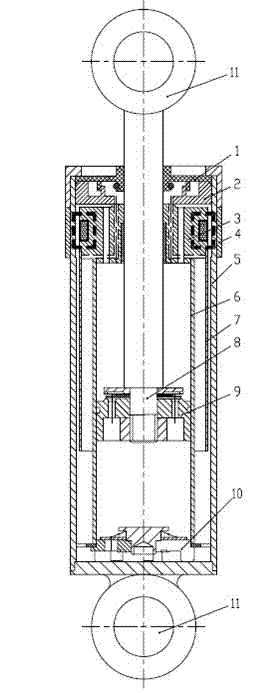

Magneto-rheological pump type variable-damping shock absorber

A magnetorheological and shock absorber technology, used in shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problem that the shock absorber cannot reduce the vibration performance, cannot achieve the vibration reduction effect, and the sealing element fails. problem, to achieve the effect of sensitive vibration response, avoid premature failure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

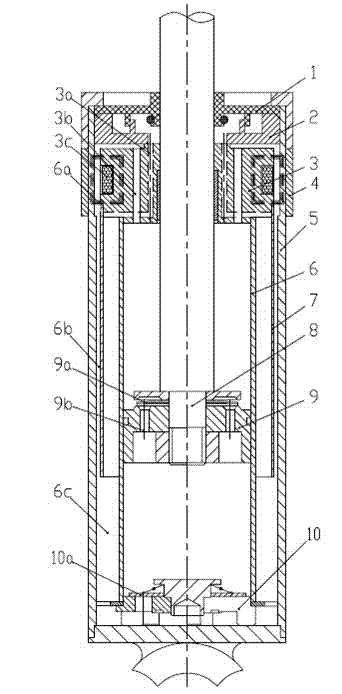

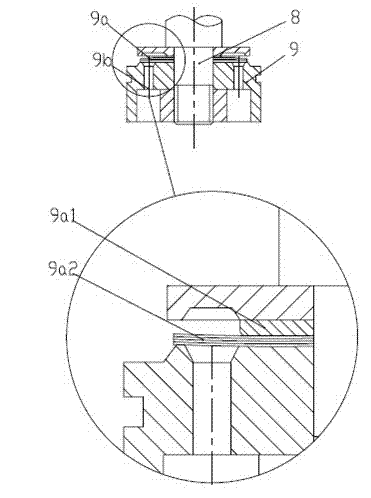

[0024] see Figure 5 , is the second embodiment of the present invention, the electromagnetic coil 3c is installed on the guide 3, and the effective magnetic field is divided into two parts: one part is concentrated between the oil seal seat 2 and the upper end surface of the guide 3; the other part is concentrated on the outer cylinder 5, Between the side of the wind deflector 7 and the guide 3.

[0025] see Figure 6 , is the third embodiment of the present invention, three (or more) electromagnetic coils 3c are installed on the guide 3, and the effective magnetic field is concentrated between the outer cylinder 5, the shroud 7 and the side of the guide 3.

[0026] see Figure 7 , is Embodiment 4 of the present invention, three (or more) electromagnetic coils 3c are installed on the guider 3, Embodiment 4 combines the characteristics of Embodiment 2 and Embodiment 3, and the effective magnetic field is divided into two parts: one part concentrates Between the oil seal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com