Novel double balance reducer for pumping units

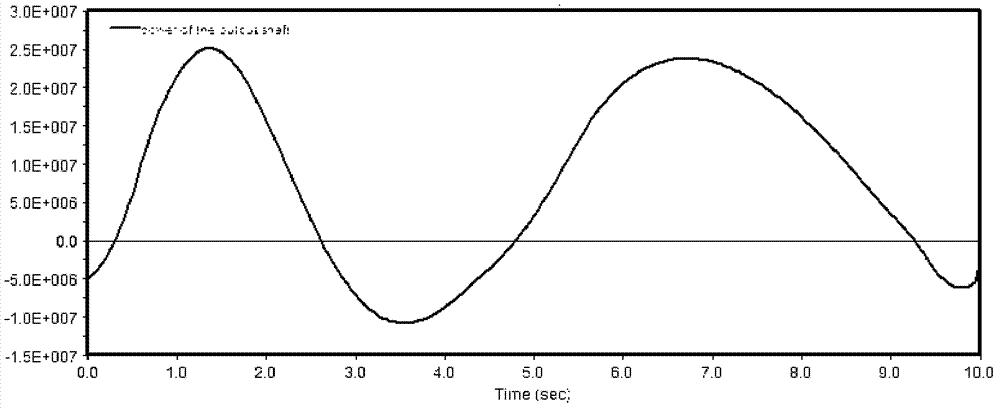

A technology of double balance and reducer, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of laborious energy consumption of large horse-drawn carts, large fluctuations in net torque curve, and poor power supply quality of the power grid, etc., to achieve Avoid large horse-drawn carts, improve motor efficiency, and reduce the effect of power configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The application will be further explained below in conjunction with the drawings:

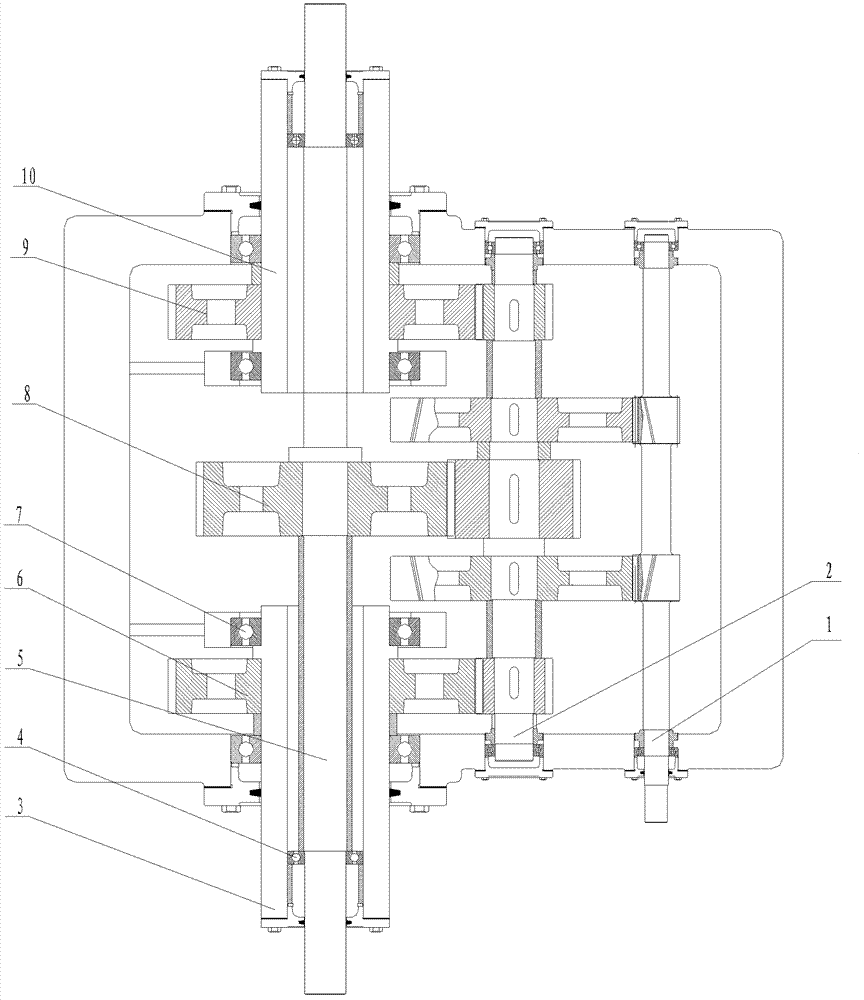

[0011] by figure 1 Shown: The new double-balanced reducer for pumping units adopts two-stage transmission, including input shaft 1, intermediate shaft 2, and output shaft. The structure of input shaft 1 and intermediate shaft 2 and the transmission mode between the two are adopted It is a conventional technology; the technical innovation of the reducer of this application is the use of a new structure of the output shaft, the output shaft is composed of a first hollow shaft 3, a second hollow shaft 10 and a solid shaft 5, the solid shaft 5 Deep groove ball bearings 4 are installed at both ends. The solid shaft 5 is supported by these two deep groove ball bearings 4 and positioned in the first hollow shaft 3 and the second hollow shaft 10. The center of the solid shaft 5 is connected to the first hollow shaft with a key. Transmission gear 7; the other two idler shafts are respectively suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com