Glass mold dovetail groove detection device

A detection device, glass mold technology, applied in the direction of measurement device, mechanical measurement device, mechanical device, etc., can solve the problems of affecting detection efficiency, high investment cost, flanging and other problems, to ensure the quality of the initial mold, high detection efficiency, Avoid bad effects

Active Publication Date: 2013-05-08

ORI MOLD TECH SUZHOU

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the dovetail groove of the initial mold exceeds the reasonable tolerance range, the flanging phenomenon will be exposed, which will affect the quality of the mouth of glass containers such as bottles and jars, and even lead to scrapping in severe cases

[0003] Based on the above reasons, which are not limited to, glass mold manufacturers usually need to strictly test the tolerance range of the dovetail groove of the initial mold, and in the actual production process must be fully tested without any omission, that is to say Sampling inspection is not performed, because the sampling inspection is accidentally qualified and cannot represent the situation that the tolerance range of the dovetail grooves of all the initial molds meets the requirements

[0004] In the existing technology, glass mold manufacturers mainly use the following three methods to measure the dovetail groove of the glass mold, that is, the dovetail groove of the initial mold (hereinafter the same): one is to use a caliper to measure, and this method is to compare the width of the dovetail groove with a caliper. For measurement, however, since one end of this dimension is located on a plane, and the other end is located at the intersection of two straight lines at 150°, the measurement error is large (the error is usually 0.1-0.3mm) and it is not enough to reliably guarantee the dimensional accuracy of the dovetail groove. The risk of a good fit with the die, in particular, since the caliper measurement is entirely controlled and judged by the inspector, it is l

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to view more

Abstract

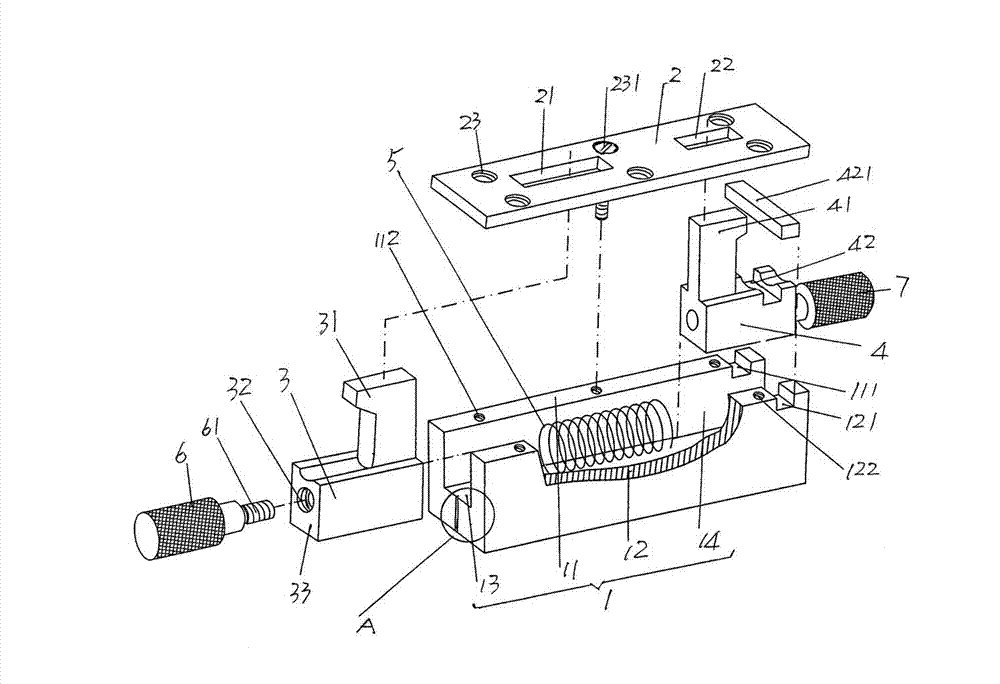

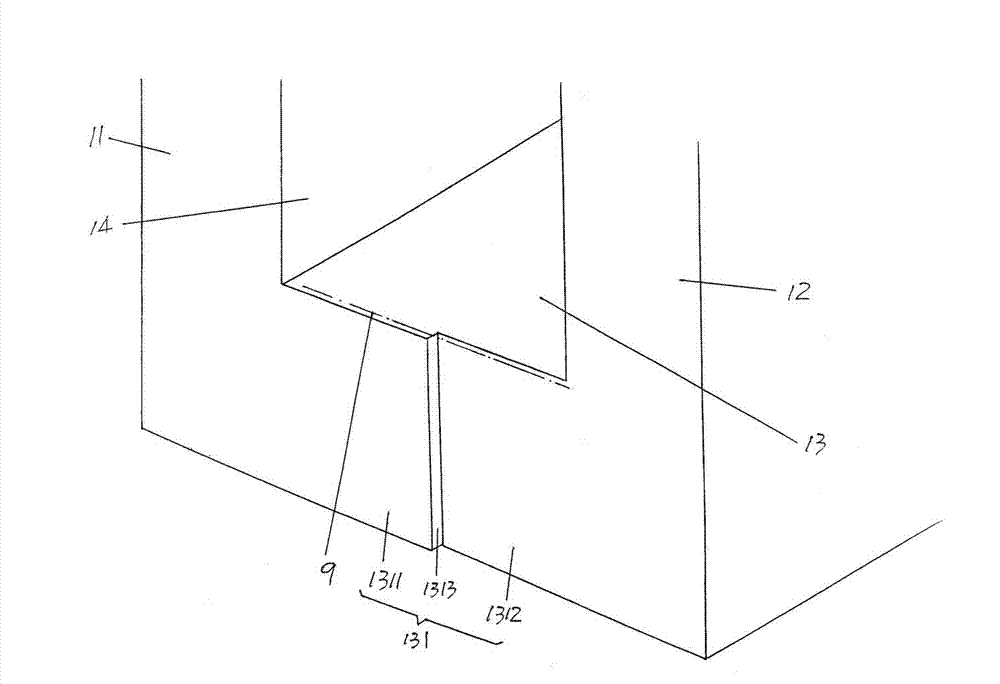

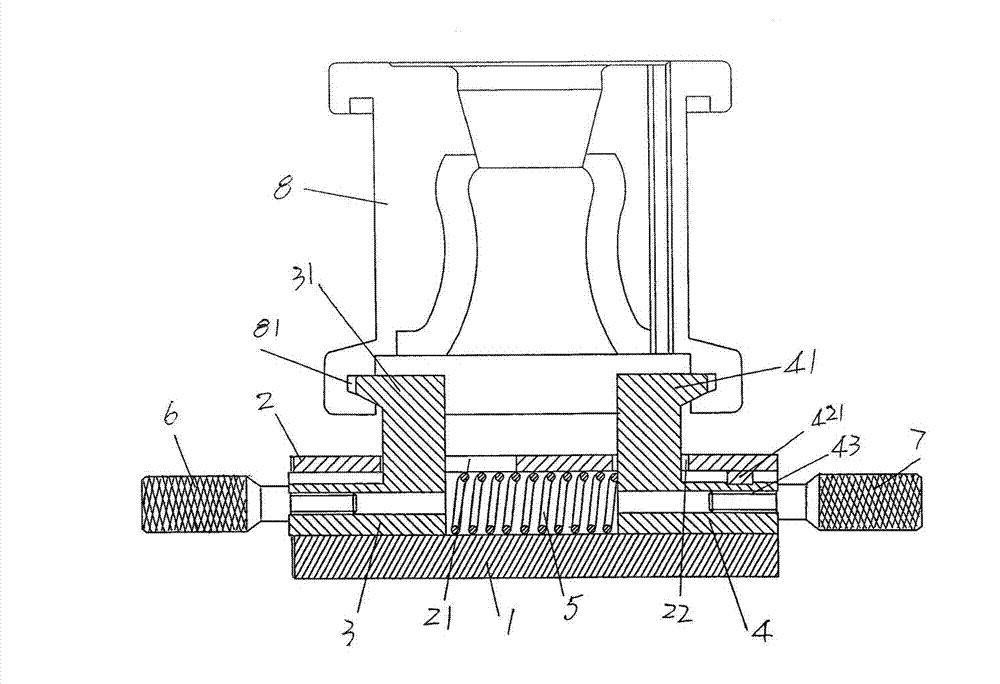

The invention provides a glass mold dovetail groove detection device and belongs to the field of tooling devices for mold detection. The glass mold dovetail groove detection device comprises a base, a cover plate, a movable measuring block, a fixed measuring block, a spring, a movable measuring block handle and a fixed measuring block handle. The base is composed of a first side wall, a second side wall and a bottom wall, a sliding cavity is formed between the first side wall and the second side wall, the bottom wall is placed on the bottom of the sidling cavity, and bottom wall end faces are respectively formed at two ends of the bottom wall. Two sides of the cover plate are respectively fixed with the top surfaces of the first side wall and the second side wall, a moveable measuring block reaching-into hole is formed at one end of the cover plate, and a fixed measuring block reaching-into hole is formed at the other end of the cover plate. A first dovetail groove measuring head is formed on the movable measuring block. A second dovetail groove measuring head is formed on the fixed measuring block. The spring is arranged in the middle of the sliding cavity. The movable measuring block handle is connected with one end of the movable measuring block. The fixed measuring block handle is connected with one end of the fixed measuring block. One bottom wall end face is composed of a first maximum tolerance face and a second maximum tolerance face, and the first maximum tolerance face and the second maximum tolerance face form a tolerance determination range step. The glass mold dovetail groove detection device is small in size, light in weight and convenient to carry, avoids being out of tolerance so as to guarantee the quality of a blank mold, and is high in detecting efficiency and wide in adaptability.

Description

technical field [0001] The invention belongs to the technical field of tooling equipment for mold detection, and in particular relates to a glass mold dovetail groove detection device. Background technique [0002] The glass mold mentioned above mainly refers to the initial mold that matches the die (the initial mold is also called the initial mold), so it can be seen that the dovetail groove of the glass mold mainly refers to the dovetail groove on the initial mold. As known to those skilled in the art, the initial mold is a mold for forming the initial shape of the bottle and jar of glass products. When manufacturing hollow glass container products, it is used as a tool for blowing and stamping out the prototype, so that the glass frit Preliminary distribution to provide guarantee for final molding. The specific function of the dovetail groove of the primary mold of the glass mold is positioning and guiding. The reasonable tolerance of the dovetail groove of the primary m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G01B5/00

Inventor 戈剑鸣

Owner ORI MOLD TECH SUZHOU

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap