Shock wave tunnel for hypersonic air vehicle ground simulation test

A ground simulation, hypersonic technology, used in ground installations, aircraft component testing, aerodynamic testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described with reference to the drawings and embodiments, but the present invention is not limited to the following embodiments.

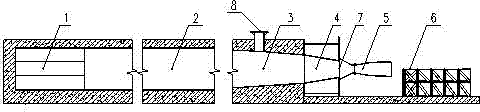

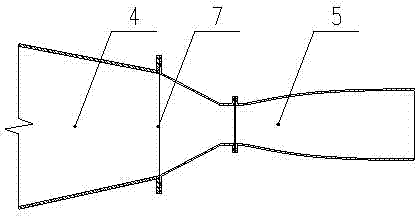

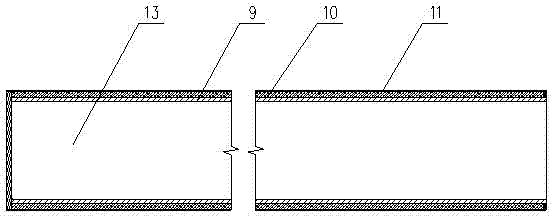

[0024] The shock tunnel for the ground simulation test of the hypersonic vehicle described in this embodiment is a test device that incorporates multiple composite structures. Such as figure 1 Shown: It mainly includes the gas-powered piston forming section 1, the driving section 2, the driven section 3, the transition section 4, the nozzle section 5 and the test section 6, and the gas-powered piston forming section 1, the driving section 2 and the driven section 3 are located at The internal structure cannot be replaced, while the transition section 4, the nozzle section 5 and the test section 6 are externally replaceable structures. The driving section 2 and the driven section 3 are composed of inner steel plates and reinforced concrete. This structure can effectively reduce the vibration effect caused by the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com