A liquid constant flow rate online analysis and monitoring device

A monitoring device and a technology of constant flow rate, applied in the preparation of test samples, electrochemical variables of materials, etc., can solve the problems of ensuring constant flow rate of effluent, easy failure of pressure reducing valves, fluctuation of measurement data, etc., to ensure scientificity and reliability. performance, good isolation and protection, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

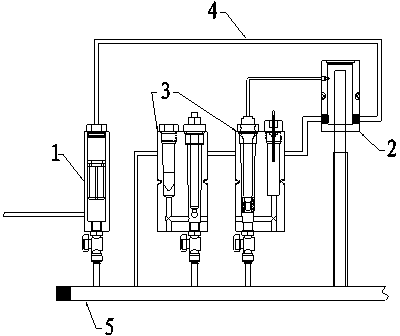

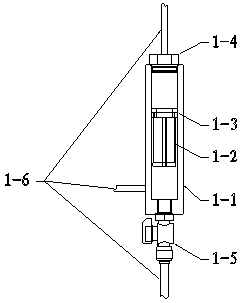

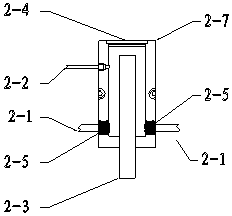

[0022] like figure 1 , 2 As shown, the present invention includes a filtering device 1, a constant current device 2, and a measuring device 3, and the three parts are respectively fixed on the substrate by screws. The filter device 1 is installed at the forefront of the sampling bypass, the constant flow device 2 is installed at the next stage of the filter device 1, and the measuring device 3 is installed at the last stage of the bypass. The three parts of the device are connected through 1 / 4" white plastic pipes. When sampling, the liquid enters the filter device 1 through the plastic pipe Ⅰ1-6, the filtrate enters the constant flow device 2 through the plastic pipe Ⅱ4, and the waste liquid generated by filtration passes through the drain pipe 5 discharge. The fluid with constant pressure and constant speed formed in the constant flow devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com