Return code judging method and driving circuit of current type industrial control bus

An industrial control and current-type technology, which is applied to fire alarms, instruments, alarms, etc., can solve problems such as large waveform changes, difficulty in distinguishing return codes, and poor amplitude. The method is accurate and simple, easy to judge, and easy to implement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

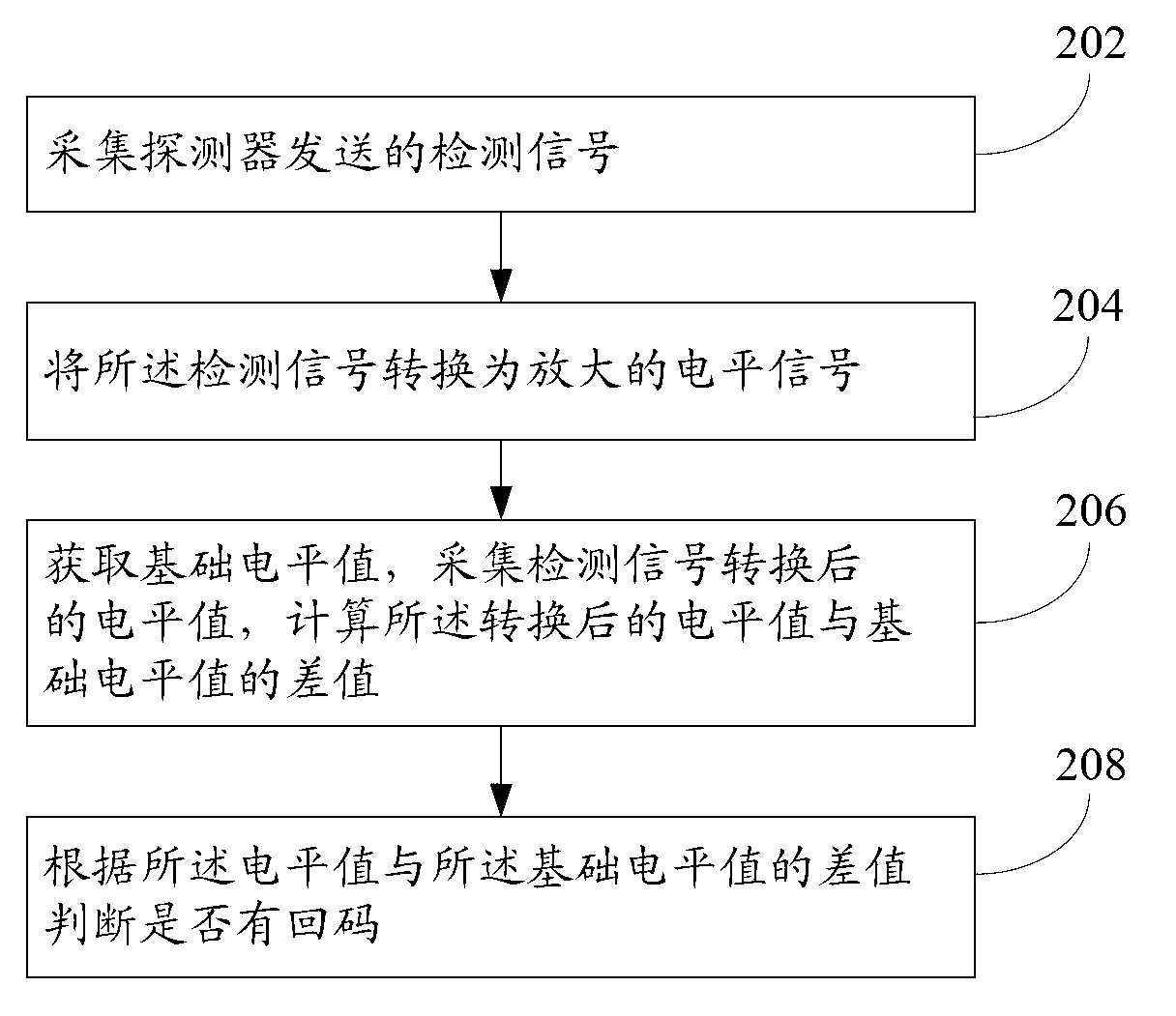

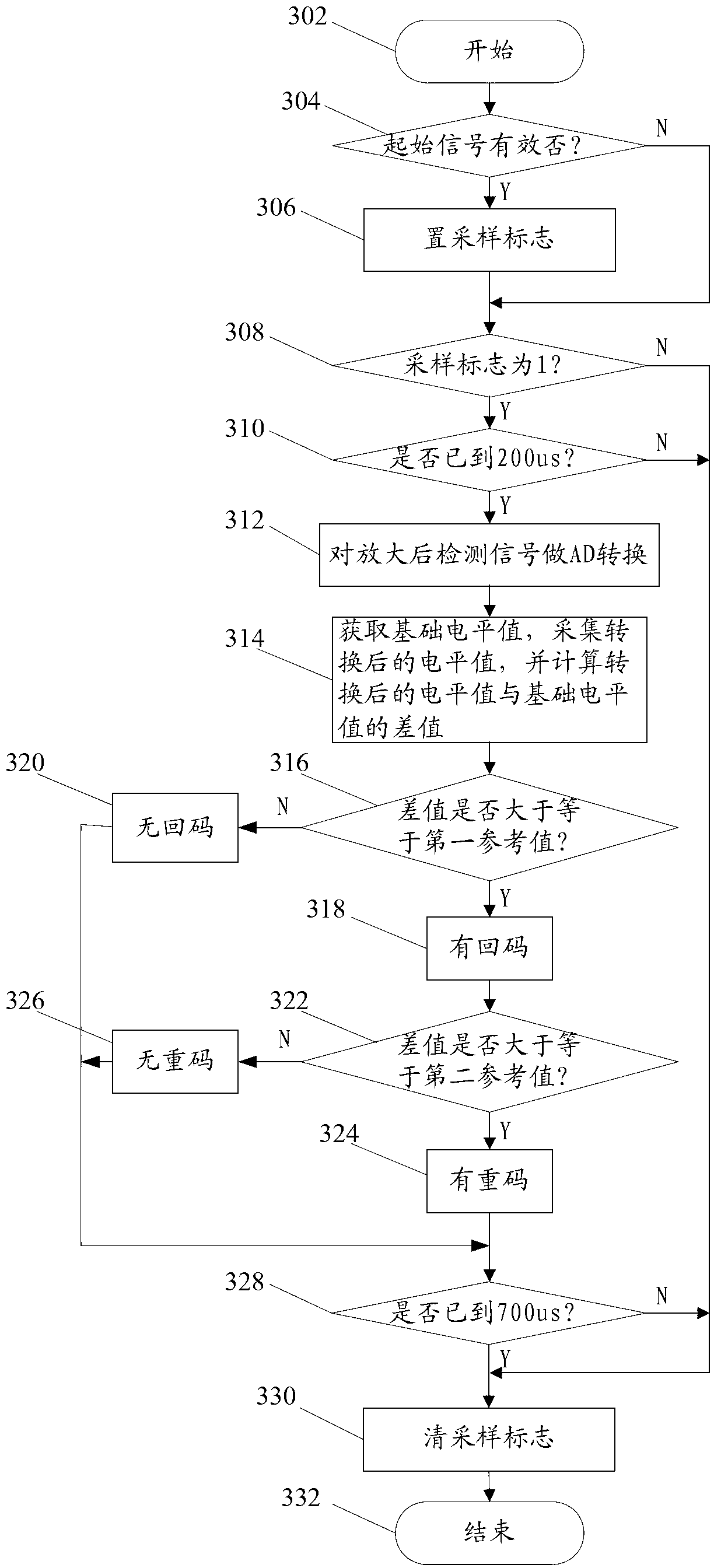

[0024] Such as figure 2 As shown, the return code judging method of the current-type industrial control bus of the present application, an implementation thereof, comprises the following steps:

[0025] Step 202: collecting the detection signal sent by the detector;

[0026] Step 204: converting the detection signal into an amplified level signal;

[0027] Step 206: Obtain the basic level value, collect the converted level value of the detection signal, that is, obtain the basic level value and the level value of the detection signal from the amplified level signal, and calculate the converted level value and the basic level value the difference between the mean values;

[0028] Step 208: Judging whether there is a return code according to the difference.

[0029] In one embodiment, the basic level value is acquired in step 206, specifically, the level value acquired at a predetermined time is set as the basic level value.

[0030] In a specific implementation manner, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com