Hollow annular traveling wave ultrasonic motor

An ultrasonic motor, hollow technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of space occupation, application limitation of ring traveling wave ultrasonic motor, etc. To achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

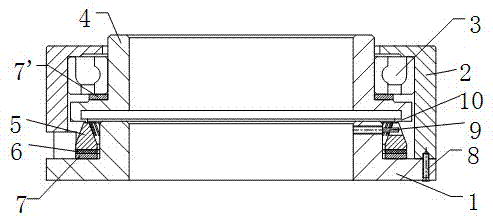

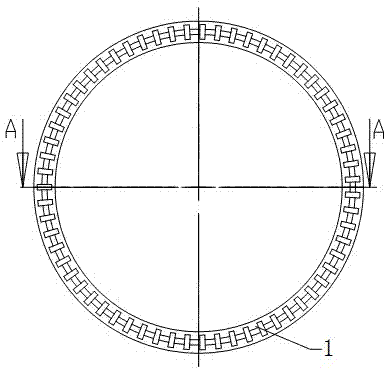

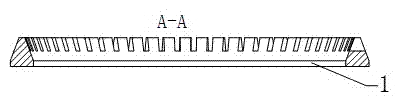

[0023] see figure 1 , figure 2 , image 3 with Figure 4 As shown, the hollow annular traveling wave ultrasonic motor of the present invention includes a base 1, a housing 2, a rotor 4, a stator 5 and piezoelectric ceramic sheets 6, and the base 1, housing 2, rotor 4 and stator 5 are all hollow ring structures. The stator 5 is arranged on the outside of the base 1 , and a piezoelectric ceramic sheet 6 is pasted on the bottom of the stator 5 . A first elastic washer 7 is also included, and the first elastic washer 7 is arranged on the bottom of the piezoelectric ceramic sheet 6 . The first elastic gasket 7 plays the role of assisting the adjustment of the pre-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com