Process method for producing traditional Chinese rice-puddings by using secondary steaming method

A process method and double-steaming technology, applied in the fields of application, food preparation, food science, etc., can solve problems such as uneven taste and color, uneven color and taste, and uneven mixing, so as to achieve no change in taste and taste, The flavors penetrate each other well, and the effect of not easily absorbing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

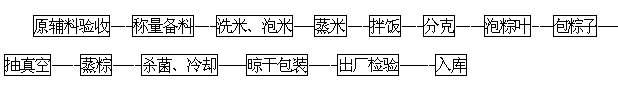

[0026] Example 1: (such as figure 1 shown)

[0027] First of all, the acceptance of raw materials is carried out: use an incubator, balance, test, weigh, and sensory test raw materials. Then weigh and prepare the material: the weighing scale is used to weigh accurately, feed the material in order, and then enter the production process.

[0028] 1. Pre-treatment: The zongye leaves are selected from July-September. Compared with the zongye leaves of other seasons, they are soft and easy to wrap. The leaves are placed in a soaking container, soaked in a steam jacketed pot, soaked in water at 100°C for 5 hours, and soaked in cold water for 5 hours. Then put it into a steam jacketed pressure cooker, the pressure is 0.12Pa, and the temperature of the water in the pot reaches 100℃, and boil for 1 hour. Make the leaves fully softened and cooked, remove the roots and impurities one by one, wash the zongy leaves with a leaf washer until there is no foreign matter, etc., and arrange th...

Embodiment 2

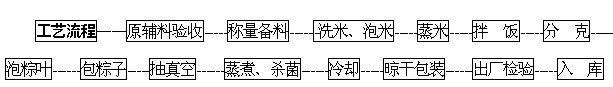

[0031] Example 2: (such as figure 2 shown)

[0032] 1. Pre-treatment: 1. The zongye leaves are selected from July-September. Compared with other seasons, the zong leaves are soft and easy to wrap. The leaves are placed in a soaking container, soaked in water at 100°C for 5 hours, and soaked in cold water for 5 hours. , and then put it into a steam jacketed pressure cooker, the pressure is 0.12Pa, and the water temperature in the pot reaches 100 ℃, and boil for 1 hour. Make the leaves fully softened and cooked, remove the roots and impurities one by one, wash the zongy leaves with a leaf washer until there is no foreign matter, etc., and arrange them for later use. 2. Wash and soak the rice. After the rice is weighed, use a professional rice washing machine to wash the rice to ensure that each grain of rice is fully cleaned. After rinsing with clean water, add a certain amount of water and soak it in a rice steaming container for 6 hours, and then steam the rice directly. 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com