Mint drying method and mint drying equipment

A technology of drying equipment and mint, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of inaccurate control of the steam pressure in the drying house and the influence of mint drying, and achieve stable drying temperature And even, the method is simple, the effect of improving the drying quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

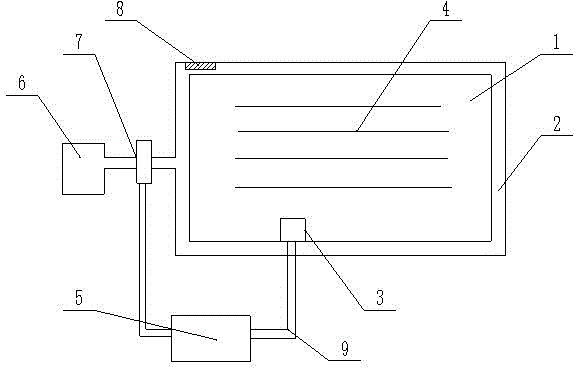

Method used

Image

Examples

Embodiment 1

[0027] A method for drying peppermint, comprising the following steps:

[0028] (1) Soak the prepared mint in water for 5 minutes, then put it in a container and put it in the room to dry;

[0029] (2) Put the dried mint into the drying rack in the drying room, place it in a single layer, open the control valve, and heat the steam into the drying room. The steam pressure is 0.2Mpa. When the temperature reaches 25°C, Stop heating for 1 hour;

[0030] (3) After one hour, use a steam pressure of 0.2 Mpa to continue heating the drying room, and turn on the drying room controller, set the drying room temperature to 35°C, and the drying time to 5 hours;

[0031] (4) After step (3), set the drying room temperature to 39°C and the drying time to 4 hours;

[0032] (5) After step (4), set the drying chamber temperature to 32°C and the drying time to 5 hours;

[0033] (6) After step (5), close the control valve and controller, and save the dried mint.

[0034] Further, the weight rat...

Embodiment 2

[0037] A method for drying peppermint, comprising the following steps:

[0038] (1) Soak the prepared mint in water for 10 minutes, then put it in a container and put it in the room to dry;

[0039] (2) Put the dried mint into the drying rack in the drying room, place it in a single layer, open the control valve, and heat the steam into the drying room. The steam pressure is 0.3Mpa. When the temperature reaches 26°C, Stop heating for 1 hour;

[0040] (3) After one hour, use a steam pressure of 0.3 Mpa to continue heating the drying room, and turn on the drying room controller, set the drying room temperature to 38°C, and the drying time to 6 hours;

[0041] (4) After step (3), set the drying room temperature to 43°C and the drying time to 5 hours;

[0042] (5) After step (4), set the drying room temperature to 34°C and the drying time to 6 hours;

[0043] (6) After step (5), close the control valve and controller, and save the dried mint.

[0044] Further, the weight ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com