Hair knotting component part for netty materials and manufacturing method thereof

A technology of mesh material and manufacturing method, applied in hairpieces, wigs, applications, etc., can solve problems such as large buckles, and achieve the effect of increasing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A hair knot assembly for mesh material and its manufacturing method according to the present invention will be described in detail below with reference to the accompanying drawings.

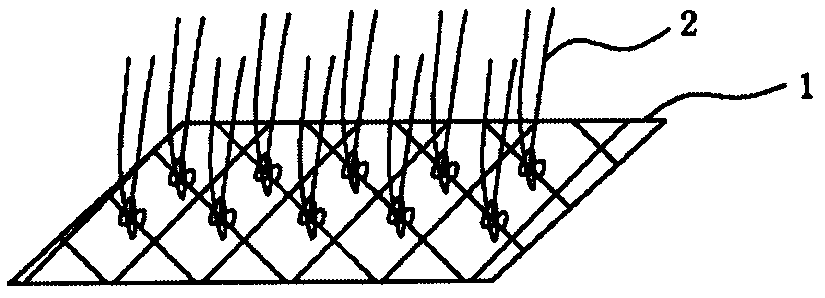

[0014] figure 1 It is a structural schematic diagram of a hair knot component used for mesh materials according to the present invention. The component includes a base net 1 and hairs 2 arranged on the base net 1 . The hair 2 is fixed on the mesh wire of the basic net 1 through the knot mode of the reverse buckle, and the basic net 1 is a mesh-like structure, and its shape and size conform to the head shape of the wig wearer. The knots formed by the hair 2 on the mesh are relatively small, and can be firmly fixed on the mesh. During the combing process, there will be no hooking and hair loss, and no knots will be exposed on the basic mesh 1. And affect the beauty.

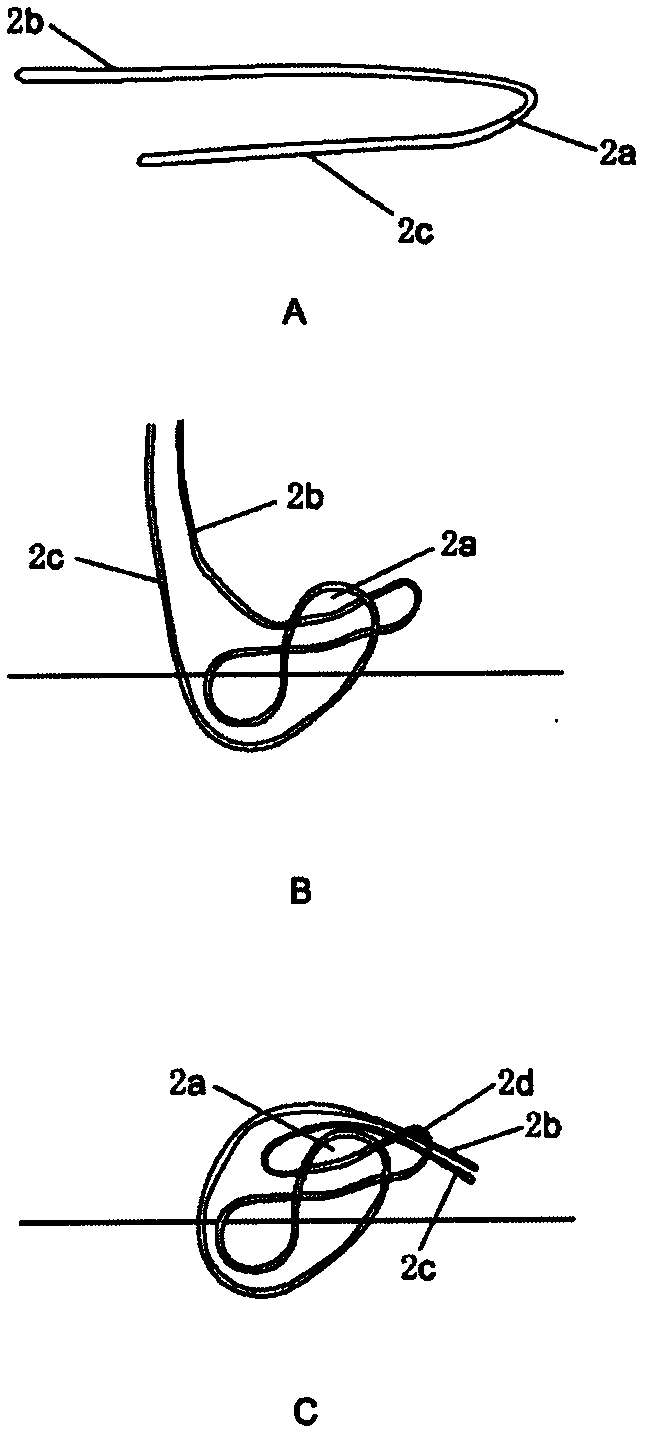

[0015] figure 2 A. figure 2 B. figure 2 C is a schematic diagram of a method for manufacturing a hair knot member fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com