Bending device for glass legs

A technology of temples and equipment, applied in the field of semi-automatic equipment, can solve the problems of uneven springback of temples, achieve consistent curvature of temples, improve production efficiency and product quality, and completely consistent bending conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

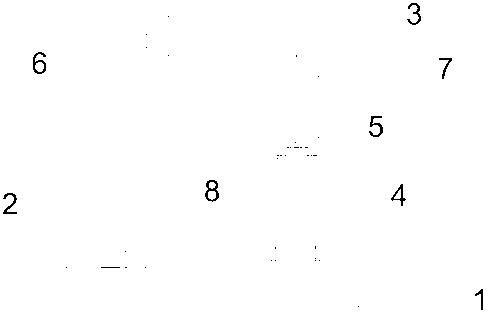

[0011] Depend on figure 1 It is known that a mirror leg bending device is composed of a base 1, a forward and reverse motor 2, a PLC controller 3, a sub-mold 4, a pressure gauge 5, a screw rod 6, a pressure rod 7 and a slot 8 for the sub-mold, The front end of the base 1 has grooves, which are used to fix the lower mold of the sub-mold 4, and the rear end is fixed with a forward and reverse motor 2 and a bracket. The inside of the bracket is provided with a screw rod 6 for controlling the up and down movement of the pressure rod 7, and the sub-mold 4 is installed on the pressure rod 7, the PLC controller 3 is connected with the forward and reverse motor 2 and the pressure gauge 5, and the forward and reverse motor 2 drives the screw rod 6 to rotate, so that the upper pressure rod 7 in the bracket passes through the PLC controller 3. Timing bending is performed on the mirror legs in the sub-mold 4 survey, and it will automatically return after forming. The lower mold of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com