A rough milling method for fir tree leaf root

A processing method, a fir-tree-shaped technology, is applied in the field of blade processing and steam turbine blade processing, and can solve the problems of high cost and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

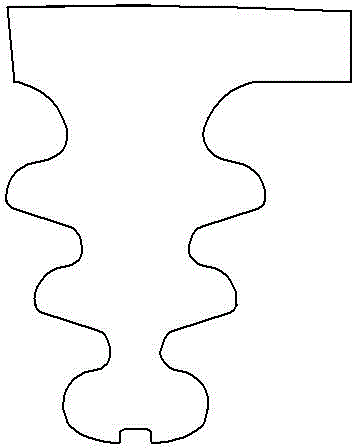

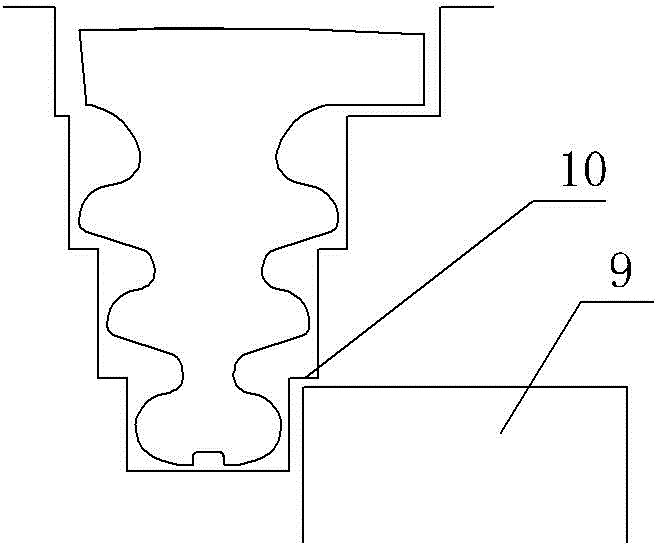

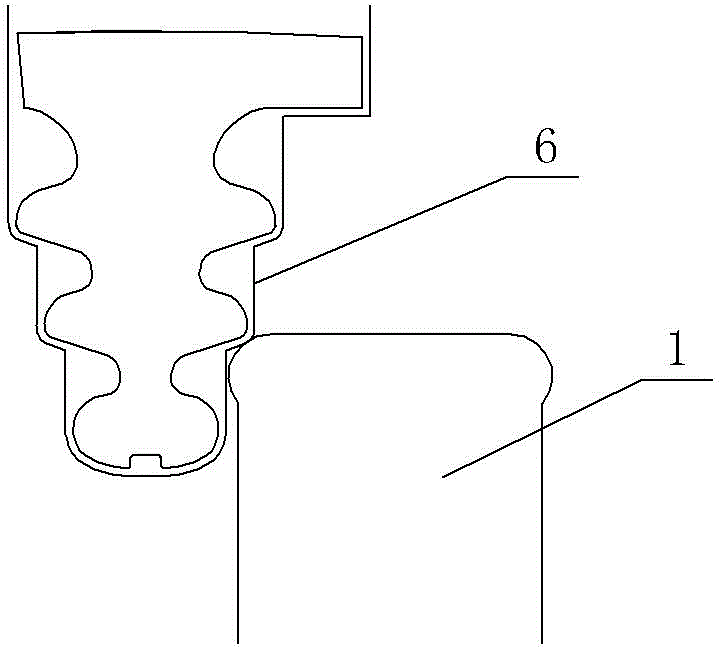

[0025] A rough milling method for a fir tree-shaped blade root. Firstly, the machining coordinate system of a four-axis horizontal CNC milling machine is established as the auxiliary driving surface for machining. direction of drive plane 4, see Figure 6 , when the process requires machining the entire blade root, the continuous driving curved surface 5 containing the blade root is made, see Figure 7 ;The tool path of the bullnose end mill is a spiral continuous machining path, without empty tool stroke; the driving auxiliary surface is to create a mesh driving point array on the driving surface, and the driving points are projected to the fir tree leaf along the specified projection vector On the root, generate the machining trajectory of the tool; the driving surface can control the direction and projection vector of the tool, reduce the stroke of empty knife and tool lifting, shorten the machining trajectory of each knife as much as possible, and reduce the processing tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com