Printing head structure

A nozzle and ink channel technology, which is applied in the field of nozzle structure, can solve problems such as empty ink phenomenon, nozzle clogging, and affect the printing quality of inkjet printers, and achieve the effects of reducing ink channel blockage, reducing empty ink, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

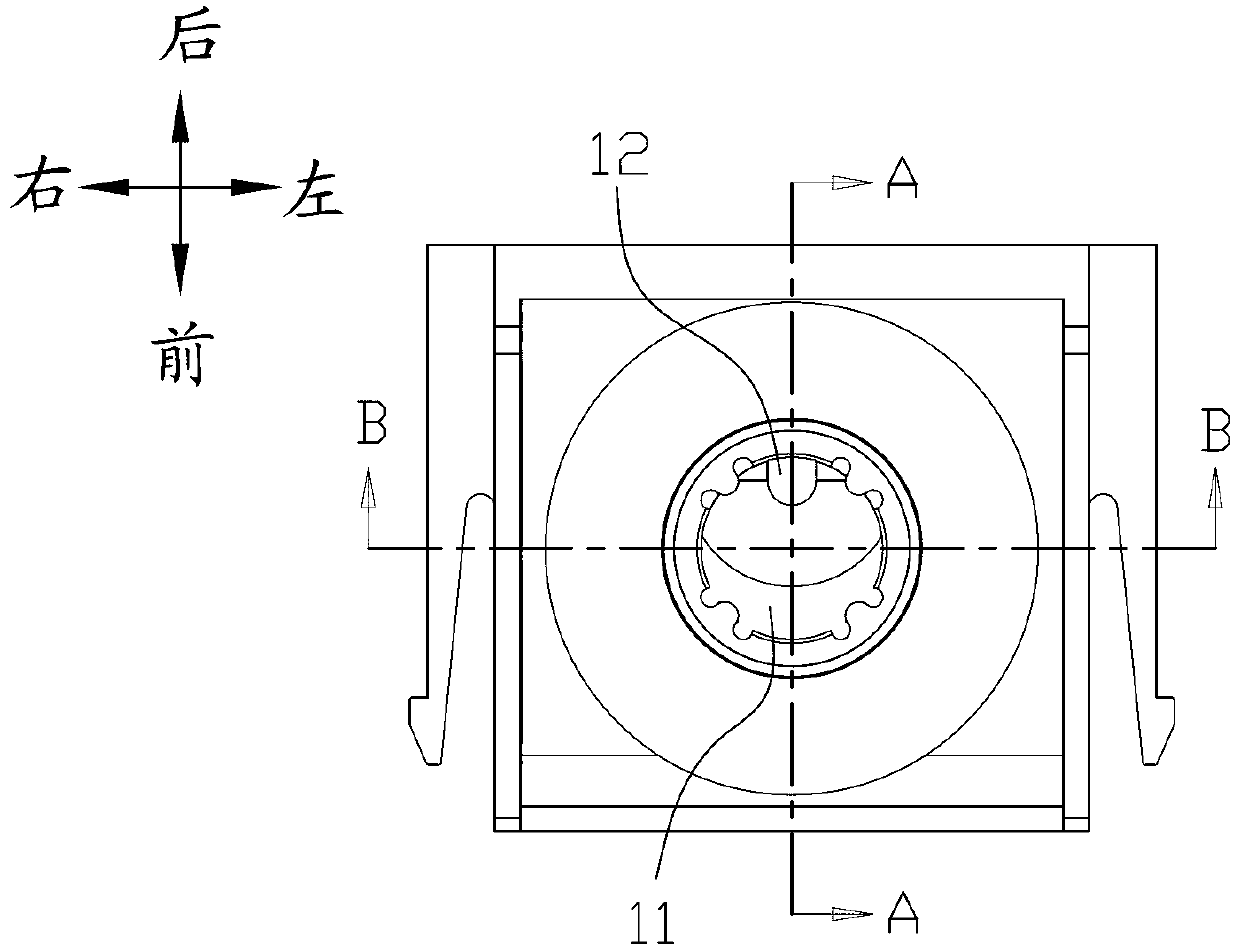

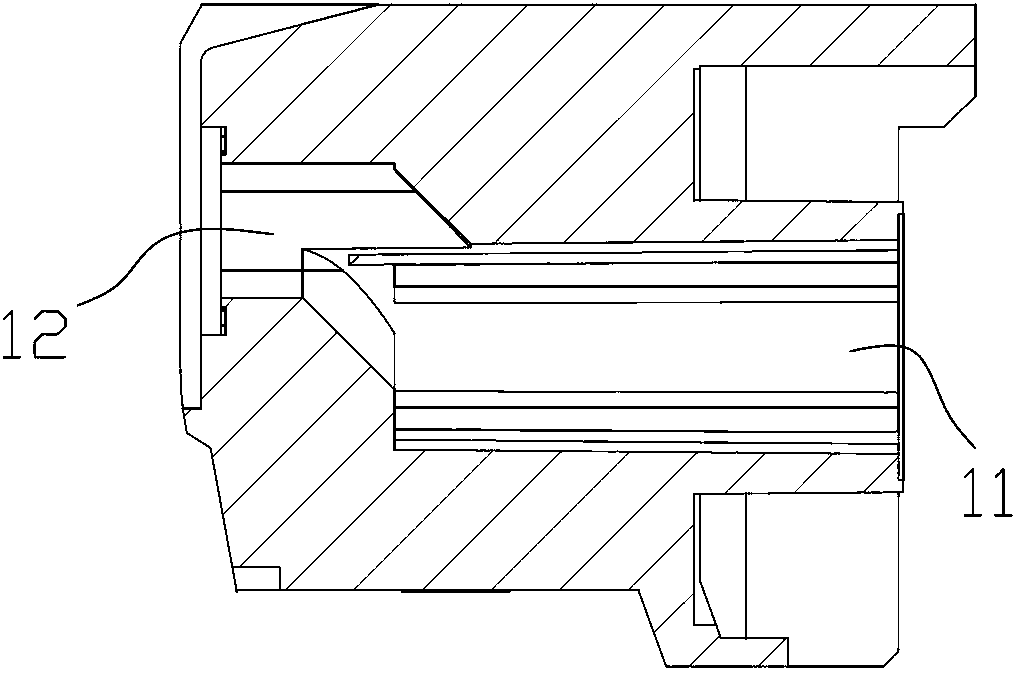

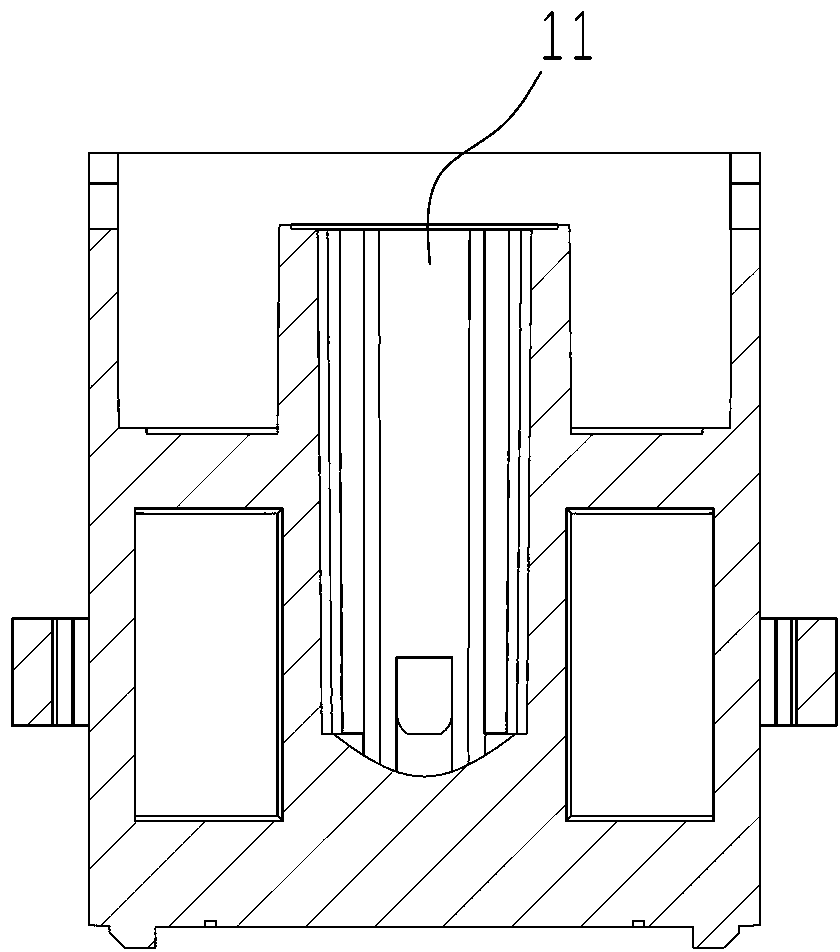

[0025] refer to Figure 1~Figure 11 , a nozzle structure of the present invention, see for details Figure 11 , used to communicate with an ink cartridge 3, the ink cartridge 3 includes an ink outlet 31, the nozzle structure includes a nozzle body 1, and the nozzle body 1 is provided with an ink outlet 11 that is docked with the ink outlet 31 of the ink cartridge 3. The lower ink channel 12 of the nozzle wafer, the upper ink channel 11 communicates with the lower ink channel 12, the upper ink channel 11 introduces the ink in the ink cartridge 3 into the lower ink channel 12, and the nozzle wafer is placed in the installation position 18 on the bottom end face of the nozzle body 1 (For details, see Figure 8 ), the ink is formed by the nozzles to form ink droplets and fall on the printing medium to form printing ink marks. The upper ink channel 11 is provided with a partition plate 13 , the partition plate 13 divides the upper ink channel 11 into several ink channels, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com