Unit frame for assembly frame of fully-mechanized coal mining hydraulic support frame

A technology of hydraulic support and assembly frame, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve the problem that the stability of the fully mechanized mining hydraulic support assembly frame is not very good, the assembly, disassembly and transportation Trouble and other problems, to achieve the effect of convenient disassembly and transportation, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

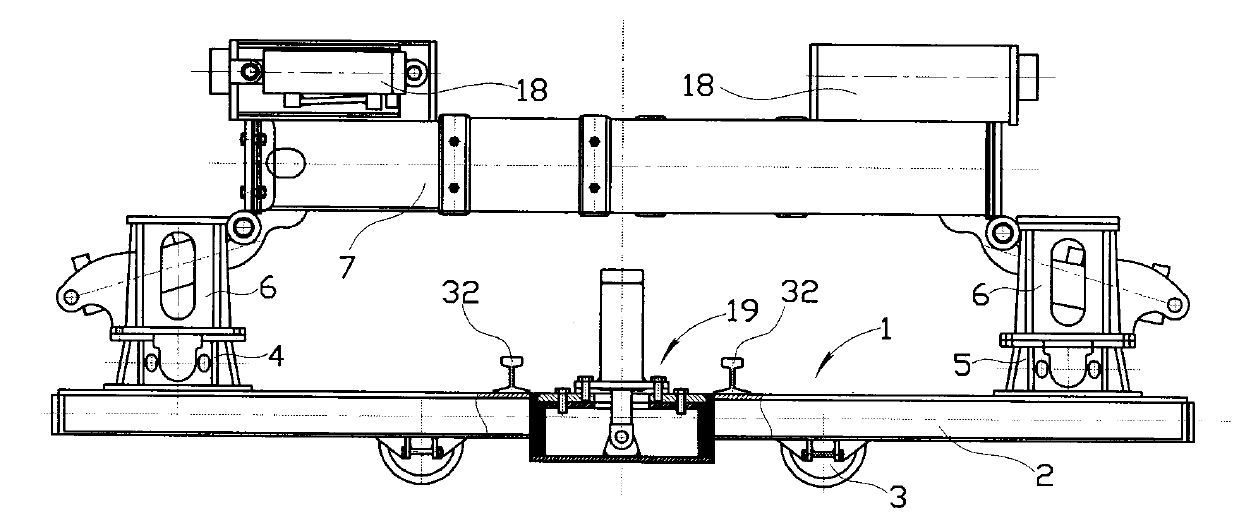

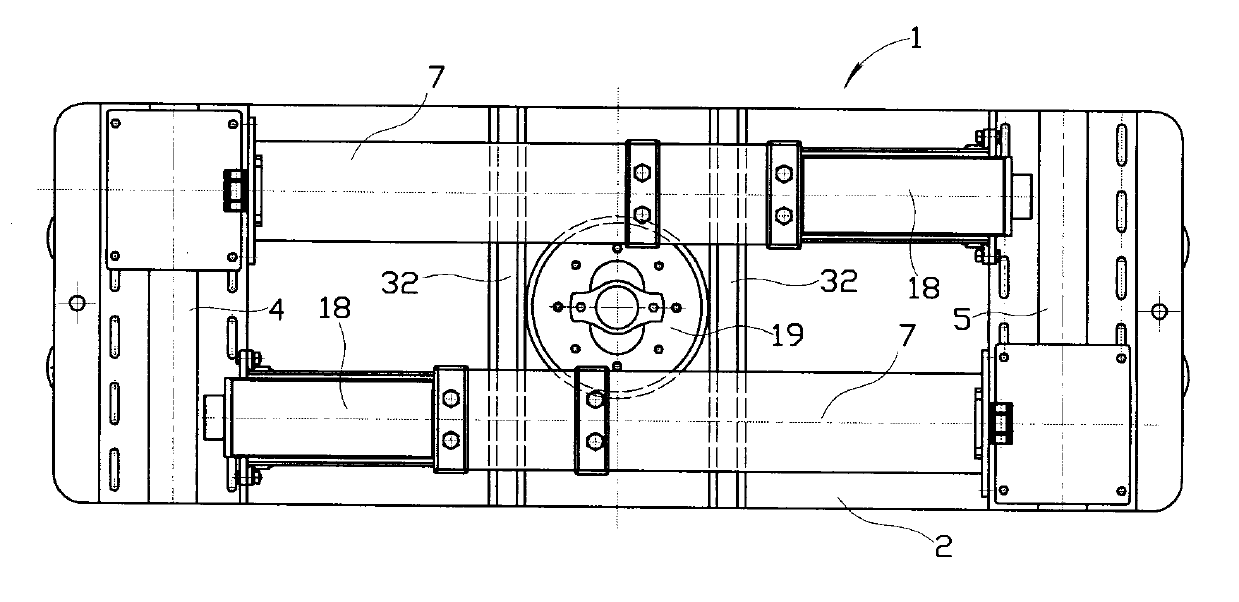

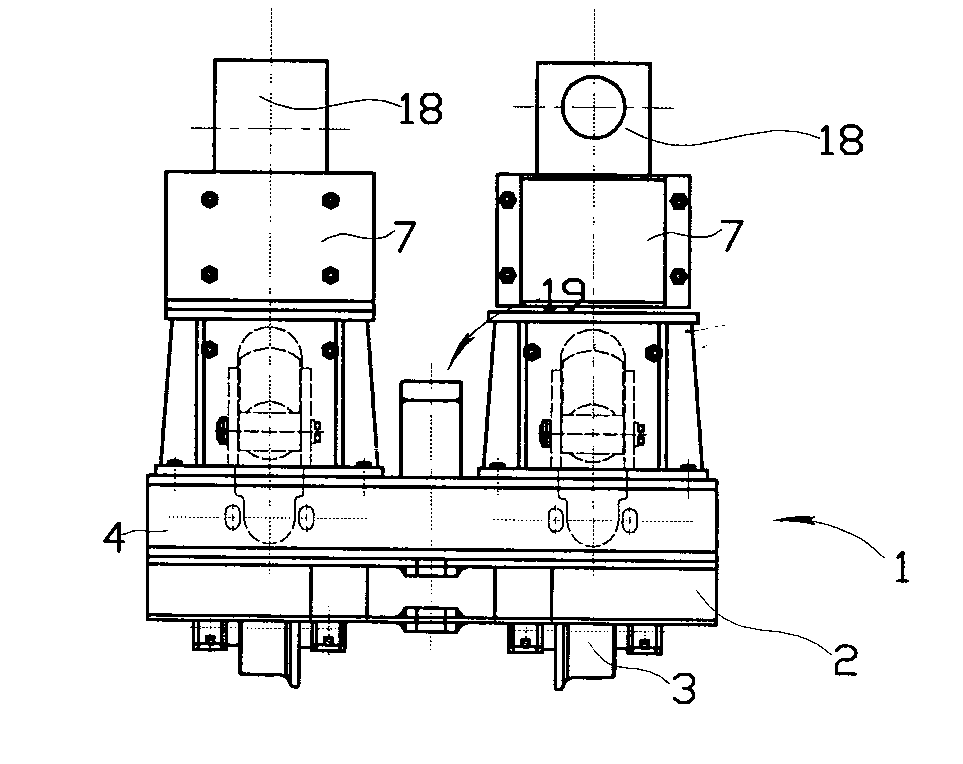

[0036] Figure 1~Figure 8 In the middle, the unit frame of the fully mechanized mining hydraulic support assembly frame has a flatbed truck 1, a flatbed truck with a horizontal truck board 2, a wheel 3 under the truck board, and two parallel left and right slides 4 and 5 on both sides of the truck board. There is a sliding block 6 on the road, a square tube column 7 is hinged on the sliding block, the square tube column has inner and outer square tubes 8, 9 sleeved together, and the lower part of the inner square tube and the upper part of the outer square tube have matching radial Connect the screw hole 10, the swing hydraulic cylinder 11 is connected between the outer square tube and the car plate, the left and right square tube columns are provided with longitudinal slits 12 on the opposite sides, and the square tube column has a length parallel to the length of the square tube column. Heavy hydraulic cylinder 13. The lower end of the lifting hydraulic cylinder is positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com