Device and method for testing high-frequency on-load frequency characteristic of large-size hydraulic cylinder

A frequency characteristic test, hydraulic cylinder technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problem of small test frequency range, sensor damage, affecting the output signal waveform and detection accuracy of the displacement sensor And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

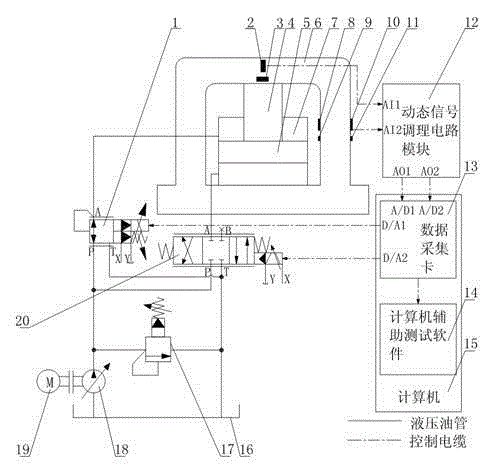

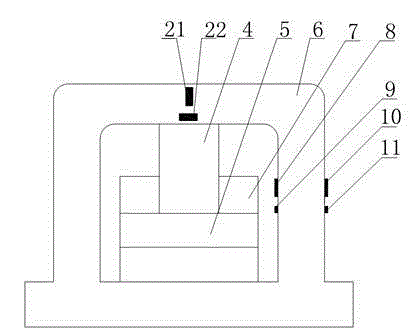

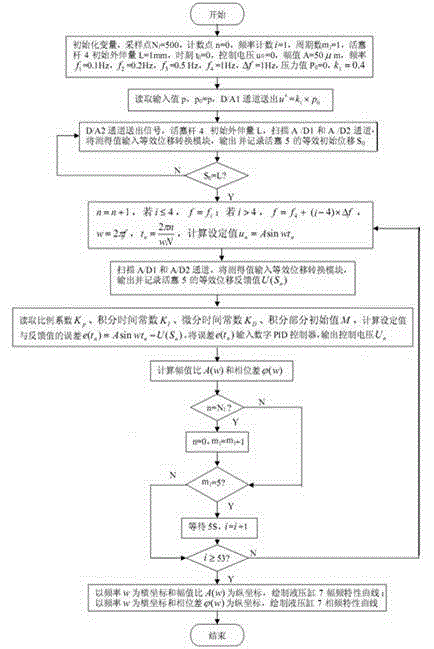

[0063] A large-scale hydraulic cylinder high-frequency load frequency characteristic testing device and testing method thereof. The test device as figure 1 As shown: the hydraulic pump 18 is coaxially connected with the motor 19, the oil suction port of the hydraulic pump 18 communicates with the oil tank 16, the oil pressure port of the hydraulic pump 18 communicates with the P port of the electro-hydraulic servo valve 20, and the A port of the electro-hydraulic servo valve 20 Or the B port communicates with the rodless cavity of the hydraulic cylinder 7 , and the T port of the electro-hydraulic servo valve 20 communicates with the oil tank 16 . The oil pressure port of the hydraulic pump 18 communicates with the P port of the three-way proportional pressure reducing valve 1, the A port of the three-way proportional pressure reducing valve 1 communicates with the rod chamber of the hydraulic cylinder 7, and the T port of the three-way proportional pressure reducing valve 1 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com