Industrial camera

A camera and industrial technology, used in TV, color TV parts, electrical components, etc., can solve the problems of low transmission speed, large volume, short transmission distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

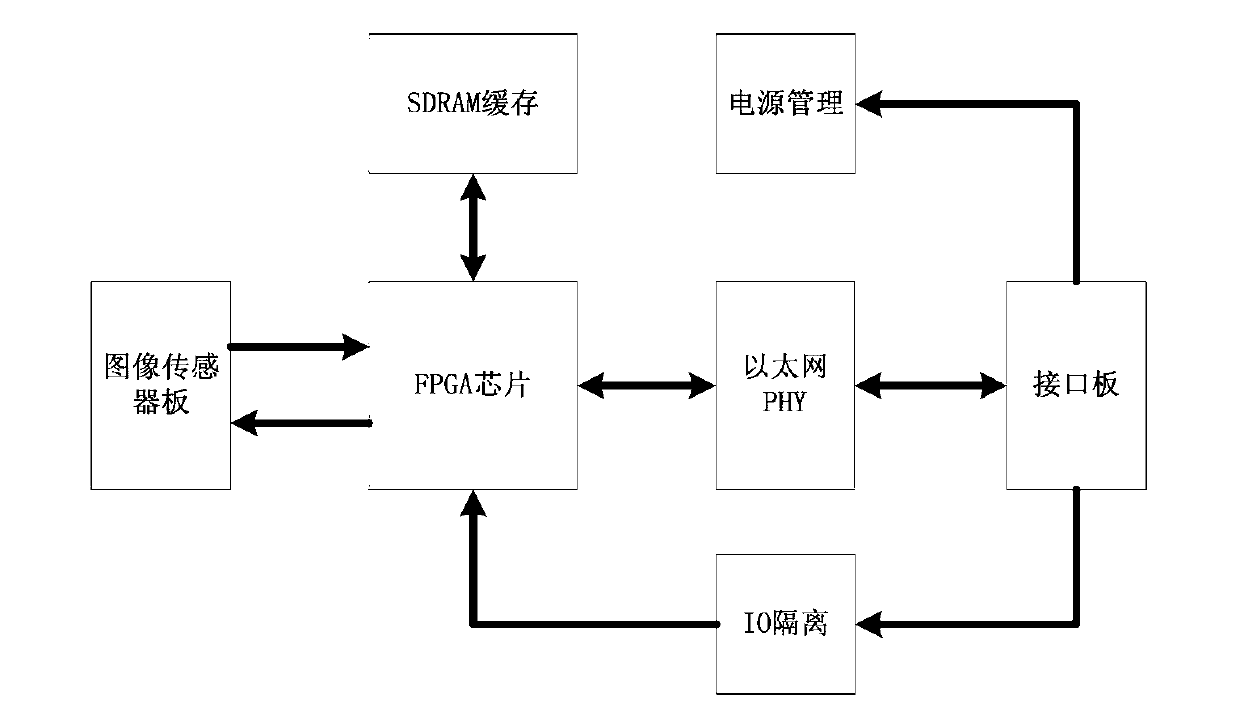

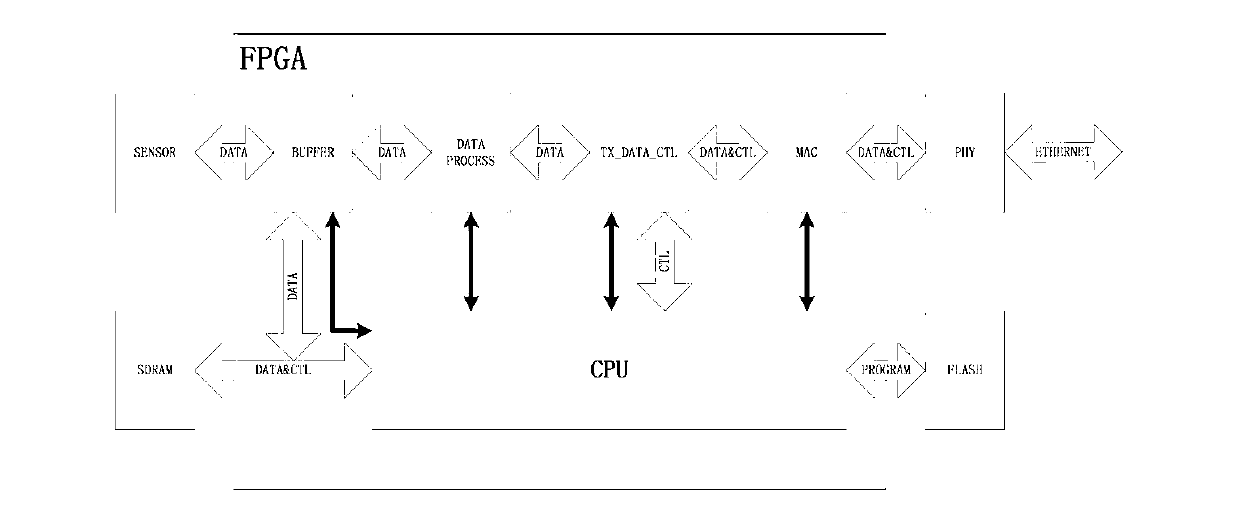

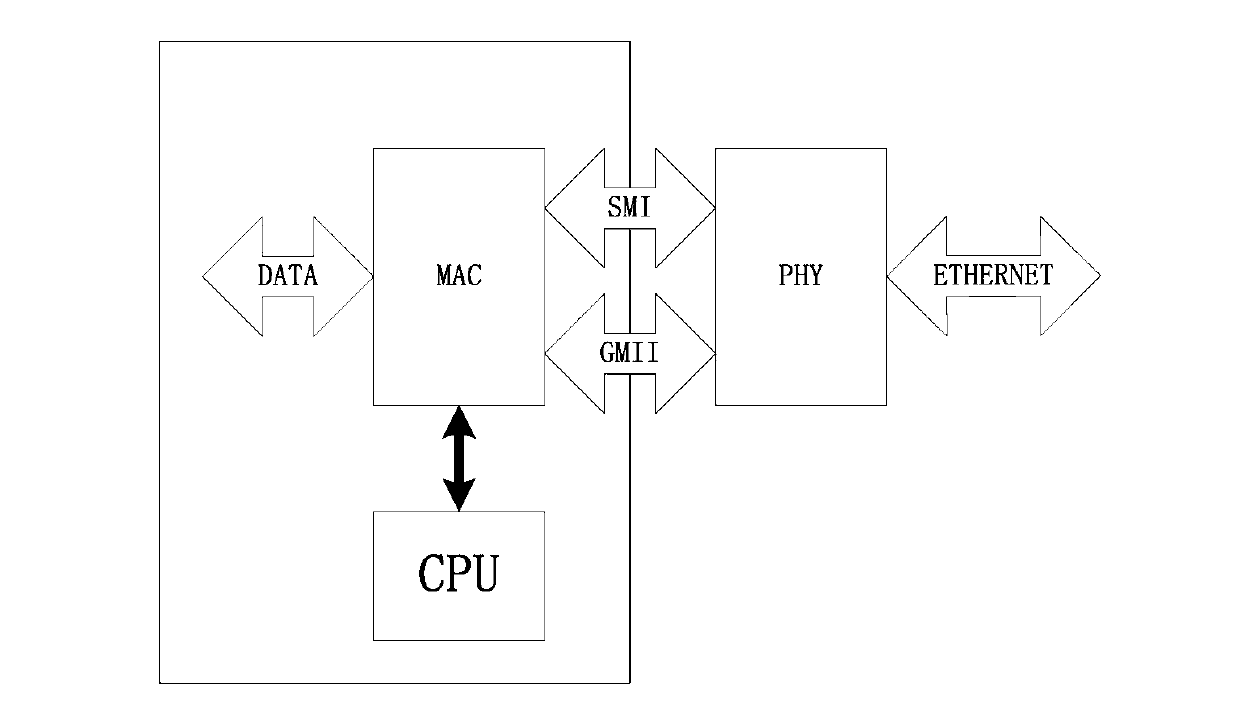

[0017] Such as figure 1 As shown, the present embodiment is an industrial camera, including a digital image sensor, an image collector and a communication interface; the image signal taken by the digital image sensor is processed by the image collector and then transmitted to the industrial control computer through the communication interface, and the communication interface is an Ethernet The network interface includes an interface board and an Ethernet physical layer board; the interface board includes an RJ45 Ethernet connector connected to the Ethernet and an I / O interface connected between the image collector and a digital sensor; the Ethernet physical layer board is connected to the Between the interface board and the image collector, the analog signal of the RJ45 Ethernet connector is processed and then input to the image collector. If it is not a digital image sensor, the output of the image sensor needs to be converted by AD to generate a digital image signal.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com