Header tank

A high-level tank and high-level technology, applied in the field of pharmaceutical equipment, can solve the problem of not being able to intuitively see the liquid level change in the high-level tank, and achieve the effects of low production cost and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

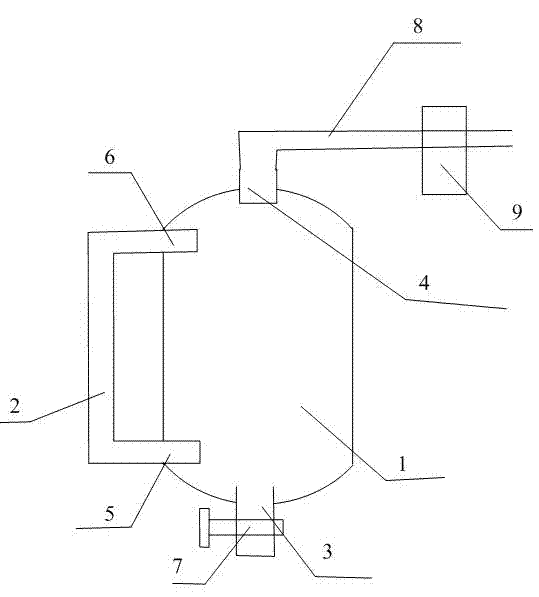

[0019] Such as figure 1 As shown, a high-level tank includes a tank body 1 and a transparent communicating pipe 2 that communicates with the tank body 1 and is parallel to the axis of the tank body. The transparent connecting pipe 2 is made of glass material. The tank body is made of carbon steel or stainless steel; enamel material can also be used; the specific situation can be selected according to the medium contained in the tank body.

[0020] A discharge port 3 is provided at the bottom of the tank body, and a feed port 4 is provided at the top. The discharge port 3 is provided with a discharge valve 7 . The feed port is connected with a feed pipe 8, and a feed adjustment device 9 for adjusting the feed speed is provided on the feed pipe.

[0021] The side wall of the tank is provided with a lower opening 5 and a higher opening 6, and the upper and lower ends of the transparent communicating pipe are respectively connected to the tank through the lower opening and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com