Automatic cleaning machine of sleeve tube

A technology for automatic cleaning machines and casings, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. The structure design is scientific and reasonable, the effect of preventing the entanglement and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

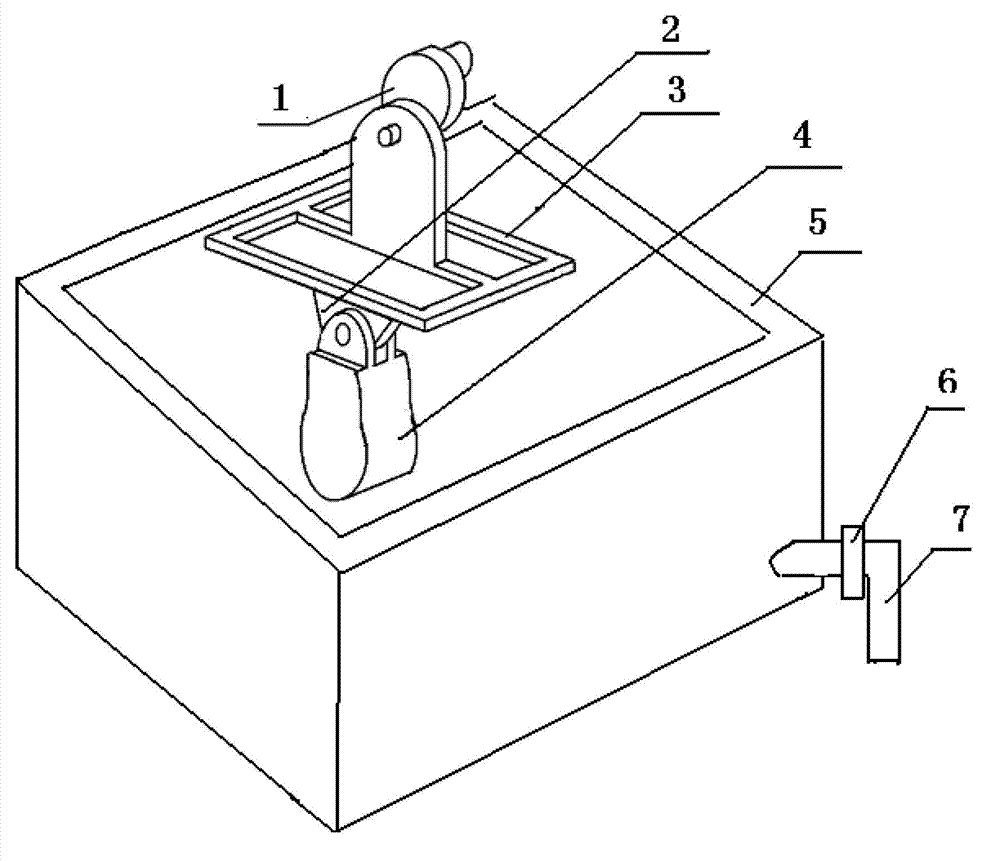

[0017] An automatic casing cleaning machine, which is composed of a cleaning tank 5, a motor (omitted in the figure), an eccentric wheel 1, a hammer frame 3 and a hammer 4, the eccentric wheel is driven by a motor, and the hammer frame is rotated and hoisted on the eccentric wheel , The tamping hammer is rotated and hoisted on the lower part of the ramming frame through the shaft seat 2, and the cleaning tank is placed under the ramming frame. The tamping hammer is a plurality of tamping hammers evenly distributed and hoisted on the lower part of the tamping hammer frame. A drain valve 6 is fixedly installed at the bottom of the cleaning tank, and the drain valve is connected with a drain pipe 7 .

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com