Open die forging forming process of forging stocks of large bulkhead type forge pieces

A forming process and forging technology, which is applied in the field of free forging forming process of forging blanks, can solve the problems of low forming efficiency, high difficulty of preforming, high cost, etc., and achieve the effect of high forming efficiency and improved material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

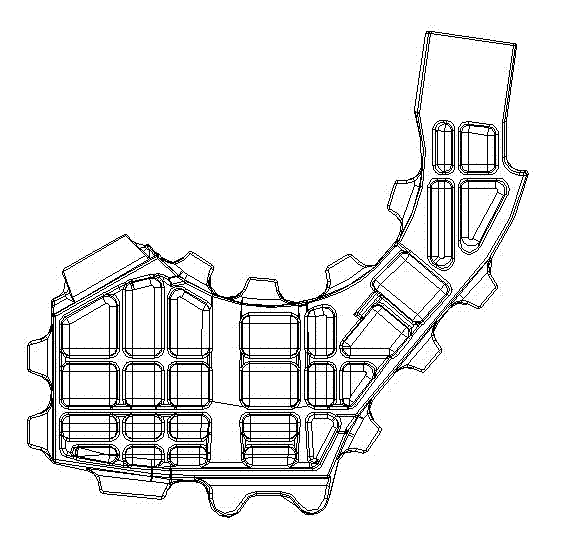

[0021] Below in conjunction with accompanying drawing, specifically describe the processing course of technique of the present invention:

[0022] Before the free forging of each fire, the bar or blank is heated and kept warm to ensure that the material is heated through, which includes the following steps:

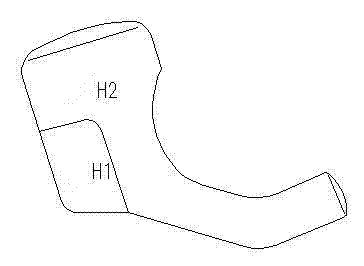

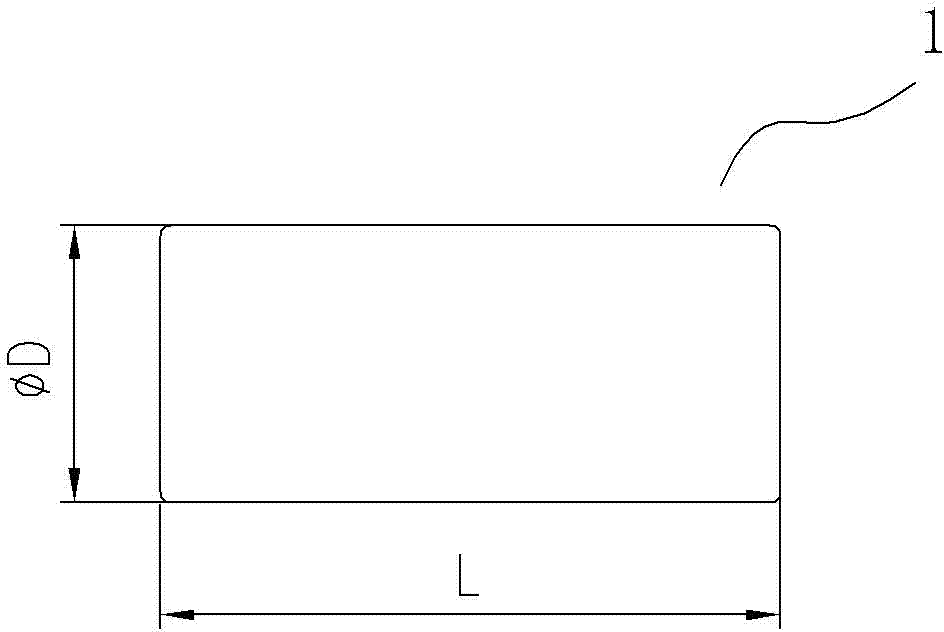

[0023] Step 1: see image 3 and Figure 4 , the bar 1 is flattened and formed into the blank 2, and the deformation ratio is 2.5:1;

[0024] Step 2: Divide the material according to the structure of the forging, and divide the flattened billet 2 to press the shoulder, see Figure 5 , Figure 4 Middle 3 is the shoulder;

[0025] Step 3: Press the neck in reverse, and press the blank after the shoulder is pressed out of the neck 4 in reverse, see Image 6 ;

[0026] Step 4: Bending forming, bending the blank as a whole along the neck 4, the degree of bending is consistent with that of the forging, see Figure 7 ;

[0027] Step 5: Flattening and forming of the rod p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com