Profile derusting device

A profile and workbench technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of human health hazards, complex structure of derusting machine, inability to remove rust in all directions, and achieve service life Long life, protection of human health, avoiding the effect of harm to the surrounding environment and human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

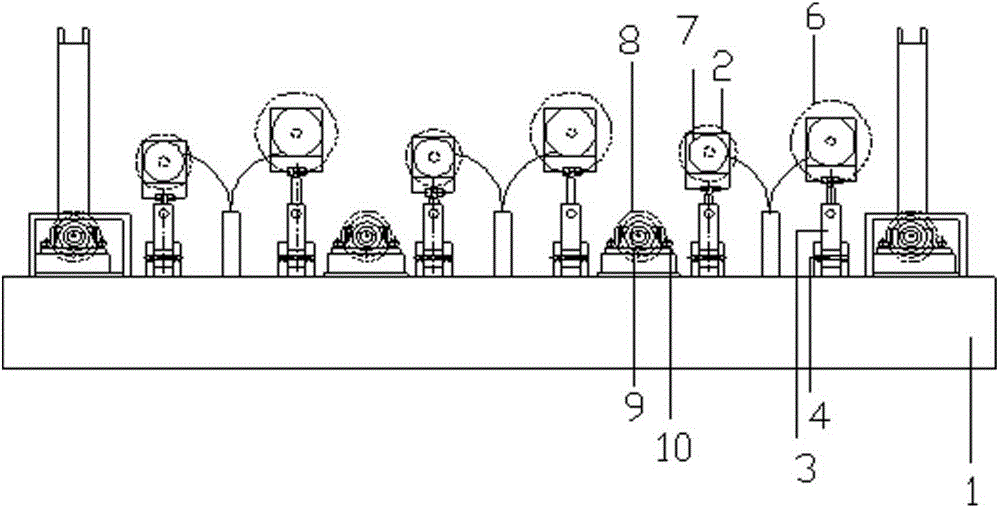

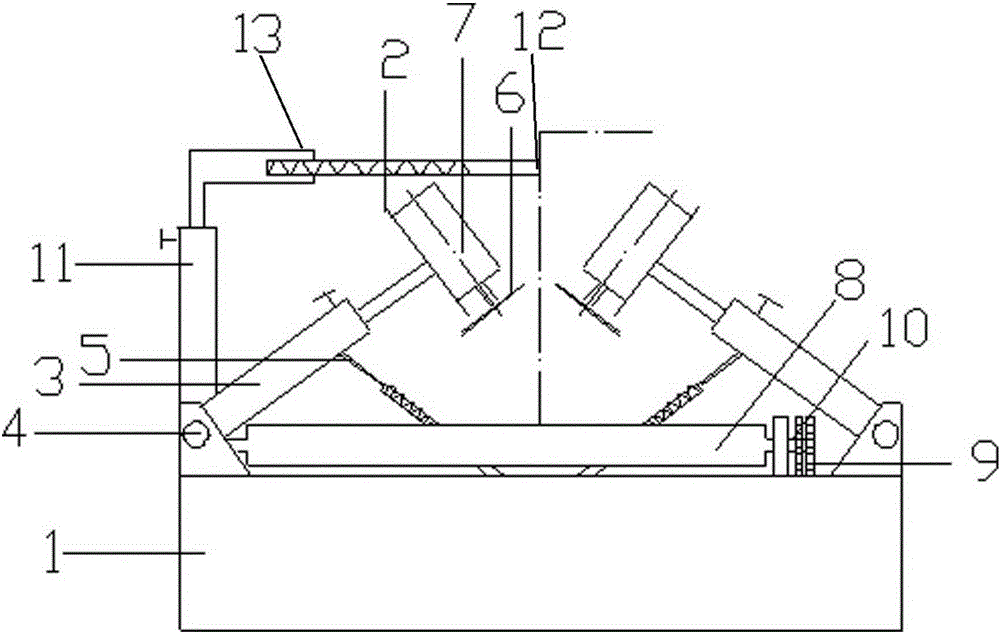

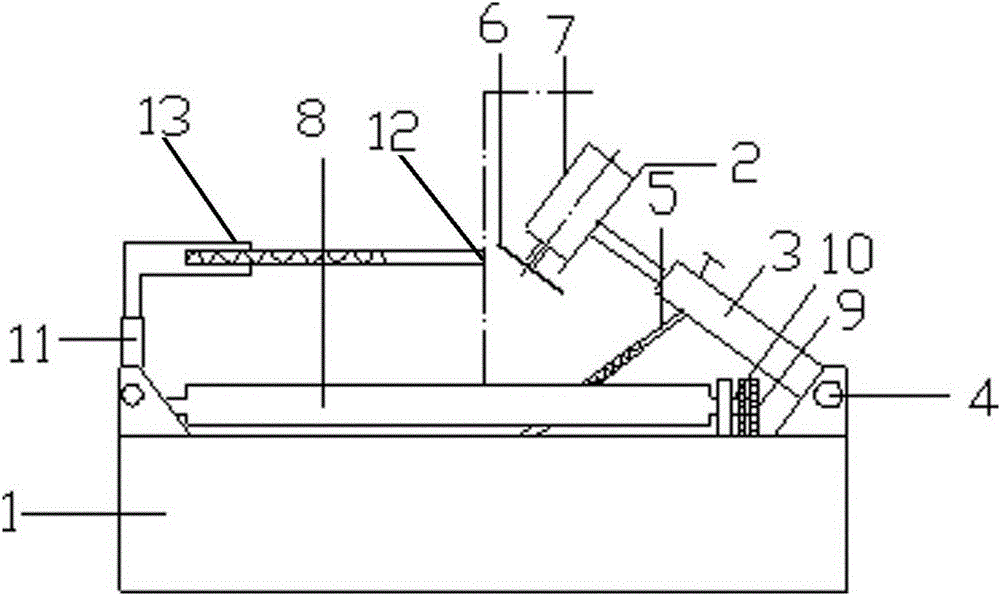

[0015] according to figure 1 , figure 2 and image 3 As shown, a profile rust removal device includes: a workbench 1, a feed roller assembly is arranged on the workbench 1, and a plurality of symmetrical grinding and rust removal assemblies of different heights are arranged on both sides of the workbench 1, or one side of the workbench There are multiple grinding and derusting components of different heights, and the other side of the workbench is provided with a supporting positioning component.

[0016] The said workbench 1 is also equipped with a casing, and the above-mentioned components are all contained in the casing.

[0017] The heights of the grinding wheels on the plurality of grinding and derusting components are different, and the heights are adjustable. The angle of the motor shaft for loading the grinding wheels is adjustable. Same side width.

[0018] The grinding and derusting assembly includes: a support sleeve 3, the support sleeve 3 is connected to one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com