Positive displacement motor rotor polishing machine tool device

A technology of screw drilling tools and rotors is applied in the field of polishing machine tools, which can solve the problems of low degree of freedom of equipment and low polishing accuracy, and achieve the effects of improving production efficiency and product qualification rate, saving metal resources, and overcoming low polishing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

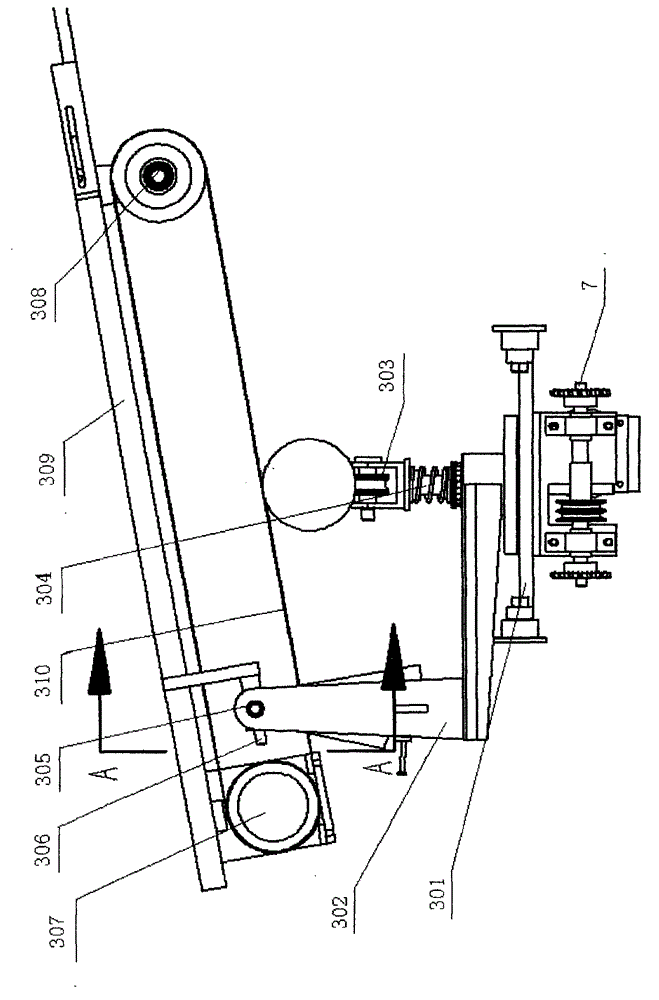

[0014] Since the present invention can move in three directions, for ease of understanding, the coordinate axes are defined as follows: the direction from the moving tailstock 1 to the geared motor 6 is the Z direction (that is, the horizontal track laying direction), the direction from the workpiece to the horizontal track 7 is the Y direction, and the polishing belt 310 The direction of movement is the X direction.

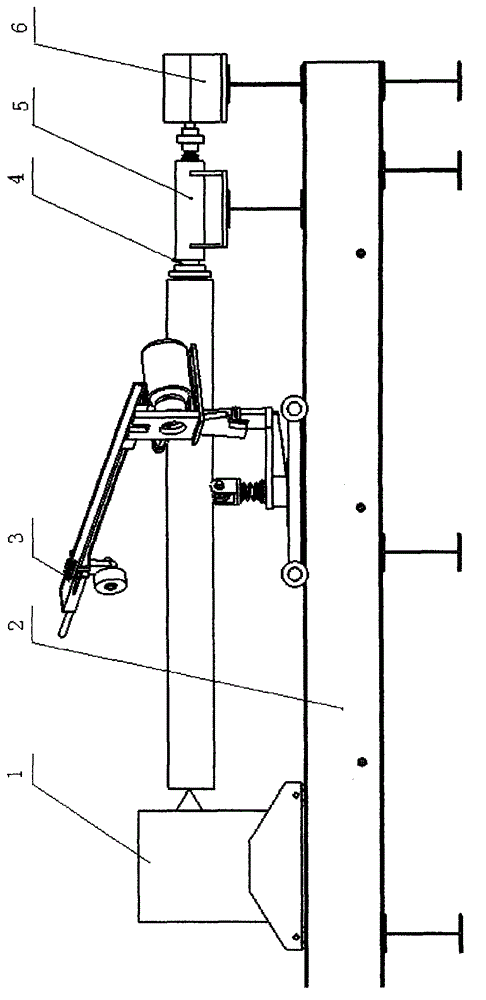

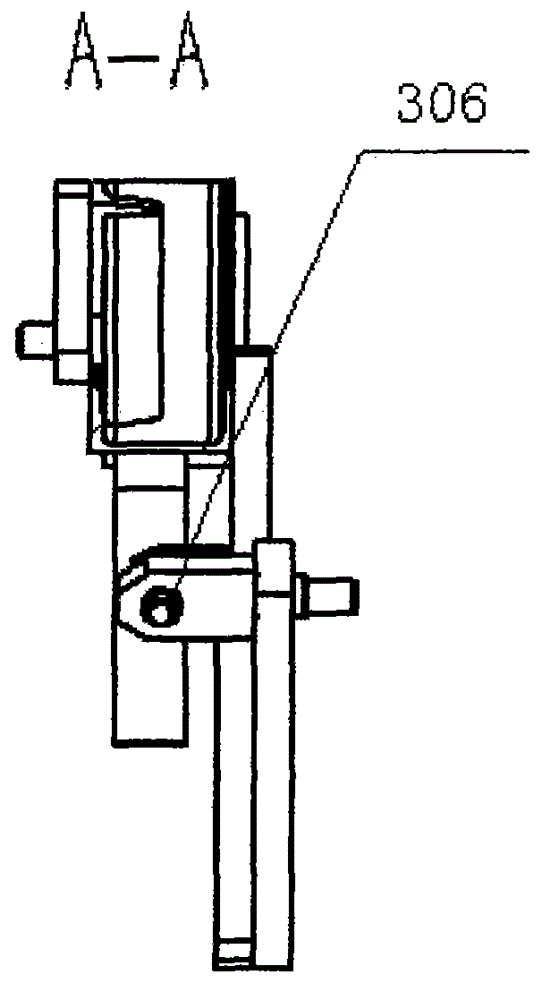

[0015] like figure 1 , 2 As shown, the screw drilling tool rotor polishing machine tool device of the present invention includes a frame 2 on which a reduction motor 6 is installed on one side and a moving tailstock 1 is installed on the other side, and is arranged on the frame 2 to be located at the moving tailstock 1 and the deceleration The horizontal track 7 between the motor 6, and the polishing assembly 3 that is installed on the horizontal track 7 and can move back and forth along the horizontal track 7 to polish the workpiece, a rotary shaft head 5 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com