A kind of plate and stacking platform for producing plate, multi-purpose table and trimming machine

A trimming machine and board technology, which is applied to other plywood/plywood appliances, household components, wood processing appliances, etc., can solve the problems of poor shape and position consistency of boards, low trimming efficiency, etc., to save processes, improve work efficiency, The effect of improving the efficiency of conveying and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

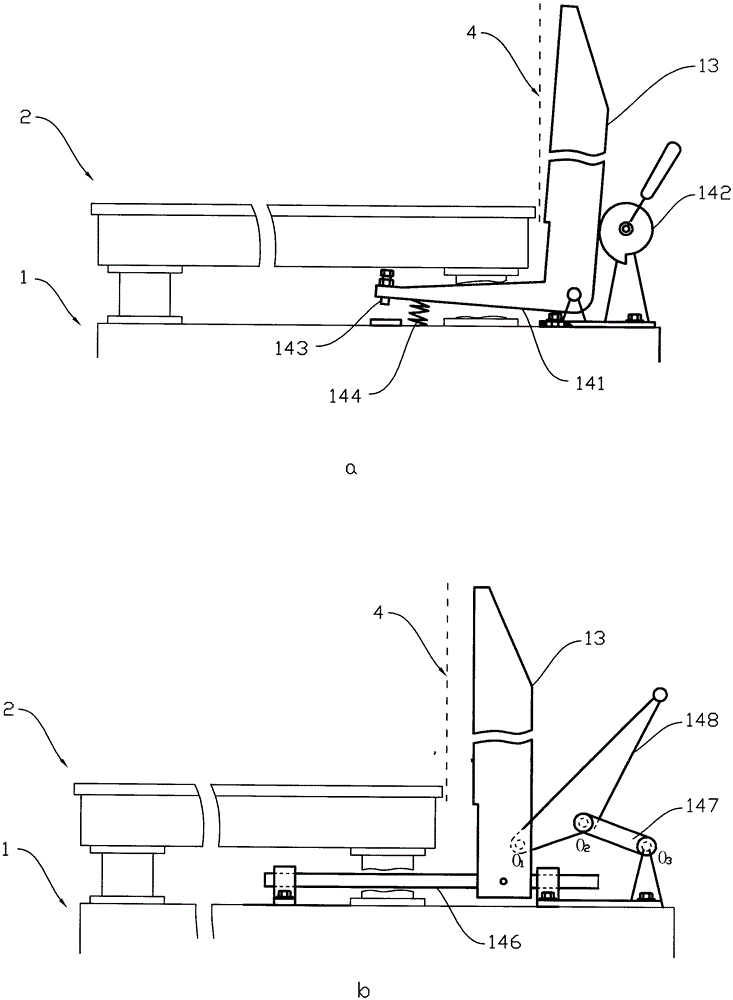

[0034] Below in conjunction with accompanying drawing, the stacking base of the present invention, multipurpose table and trimming machine will be further described.

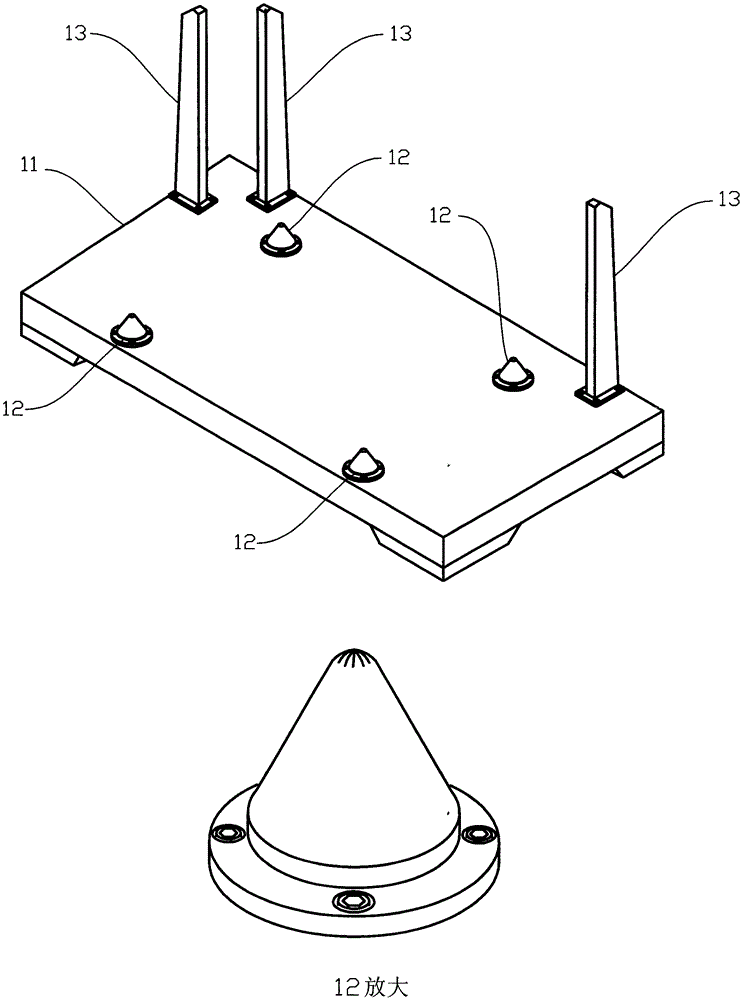

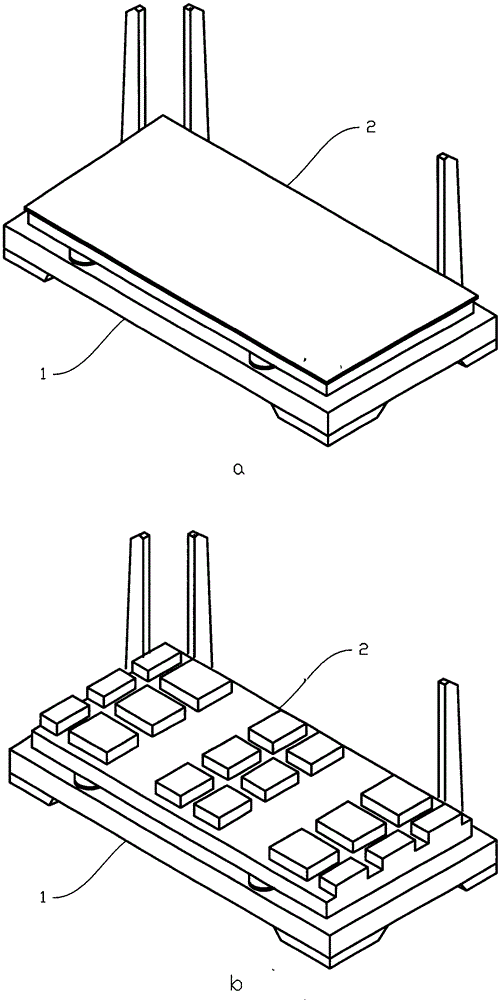

[0035] Example of a stackable stand. See figure 1 , The stacked pedestal of this example has a four short-footed rectangular platform seat 11, and four seat positioning portions 12 and three baffle plate gauges 13 are arranged on the pedestal. The seat positioning part uses an outer cone, and the bottom has a fixed plate, which is distributed correspondingly to the seat positioning part of the multi-purpose table, and is fastened to the pedestal with bolts. There is a fixed plate at the bottom of the baffle gauge, and one of the two short sides of the long side is distributed on one long side and one short side of the multi-purpose table positioned on the pedestal, basically perpendicular to the positioned multi-purpose table, according to the center limit, Take 1 / 2 board width or board length from the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com