Tape sticking type carton wrapping machine

A carton and tape technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high manufacturing cost, increased enterprise burden, high equipment maintenance cost, and achieve the effect of improving efficiency and reducing the cost of consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

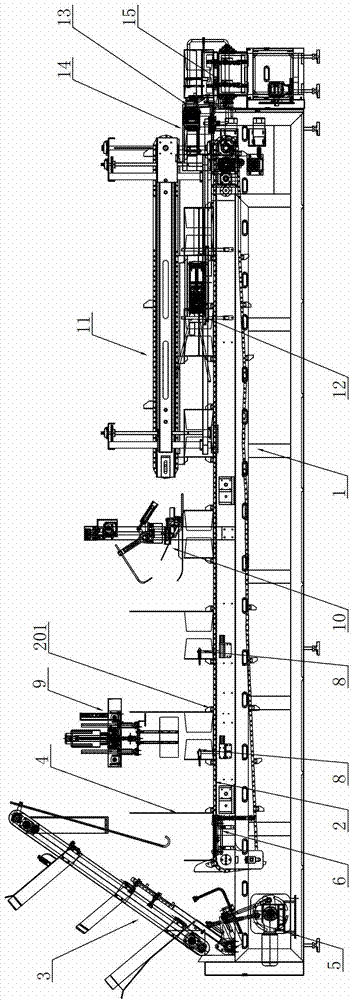

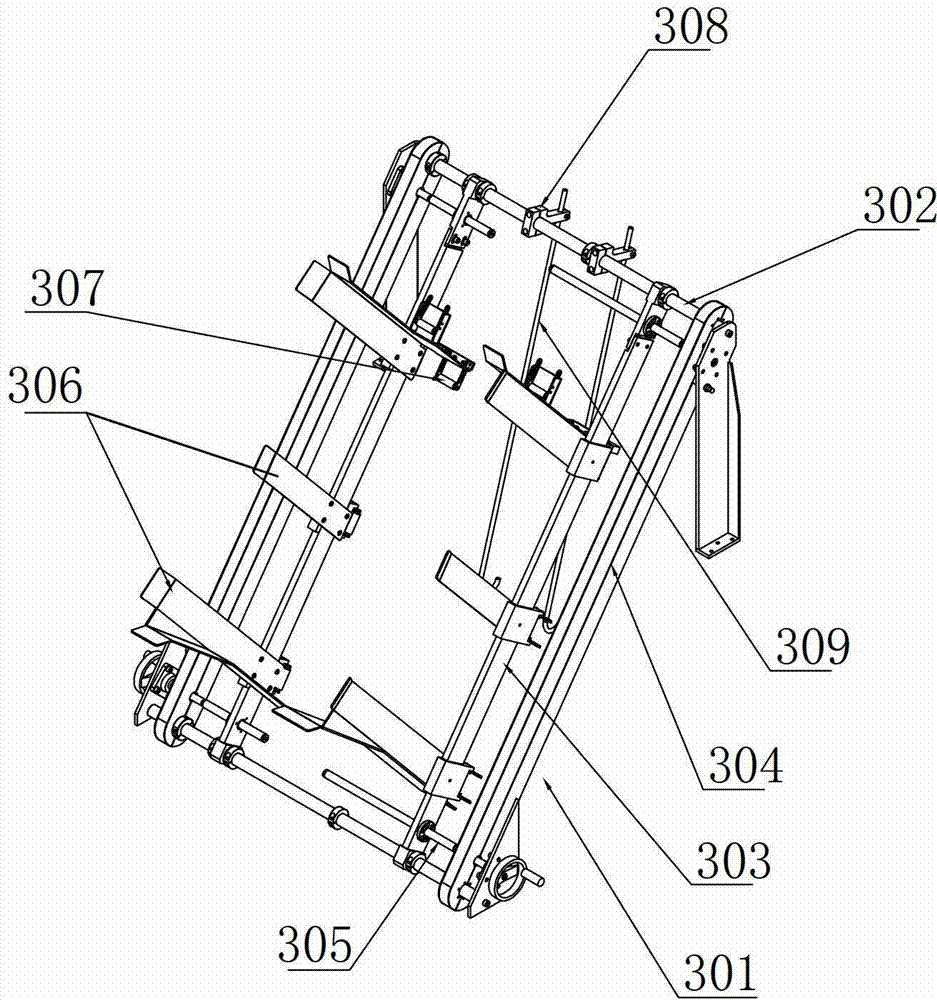

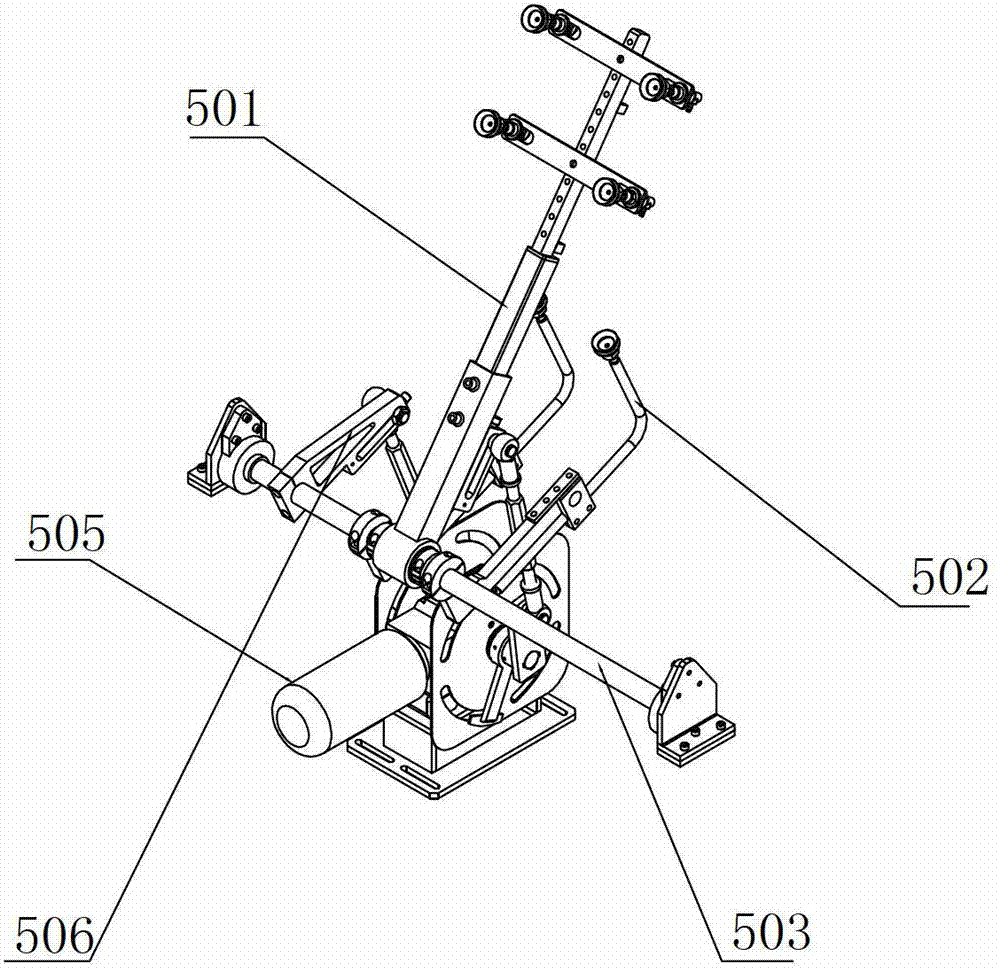

[0033] Such as figure 1 , 613, a tape-type carton wrapping machine is characterized in that it includes a frame 1, a corrugated die-cut carton conveyor belt 2 with a carton conveying station 201 on the frame 1, and the corrugated die-cut carton conveyor belt 2 The conveyor belt 2 is equipped with a length and width adjustment device for the carton conveying station 201, and the frame 1 is sequentially installed along the conveying direction with a storage box above the input end of the conveyor belt 2, which allows the die-cut cardboard to be tilted and stacked towards the conveyor belt side. Device 3, located under the die-cut cardboard storage device 3, can absorb die-cut cardboard piece by piece and form a "U"-shaped carton on the conveyor belt 4. Take the die-cut cardboard into a "U"-shaped device The carton hemming device 6 that can press the carton 4 on the conveyor belt 2, the carton hemming guide device 7 on both sides of the conveyor belt 2, the carton front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com