Reducer of elevator special for stirrers

A technology of reducer and hoist, which is applied in the direction of clockwork mechanism and winch device, etc. It can solve the problems of increasing the friction loss of the pin sleeve, reducing the efficiency of the reducer, and uneven load bearing, so as to reduce the manufacturing cost and equipment investment. , delivering a smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments.

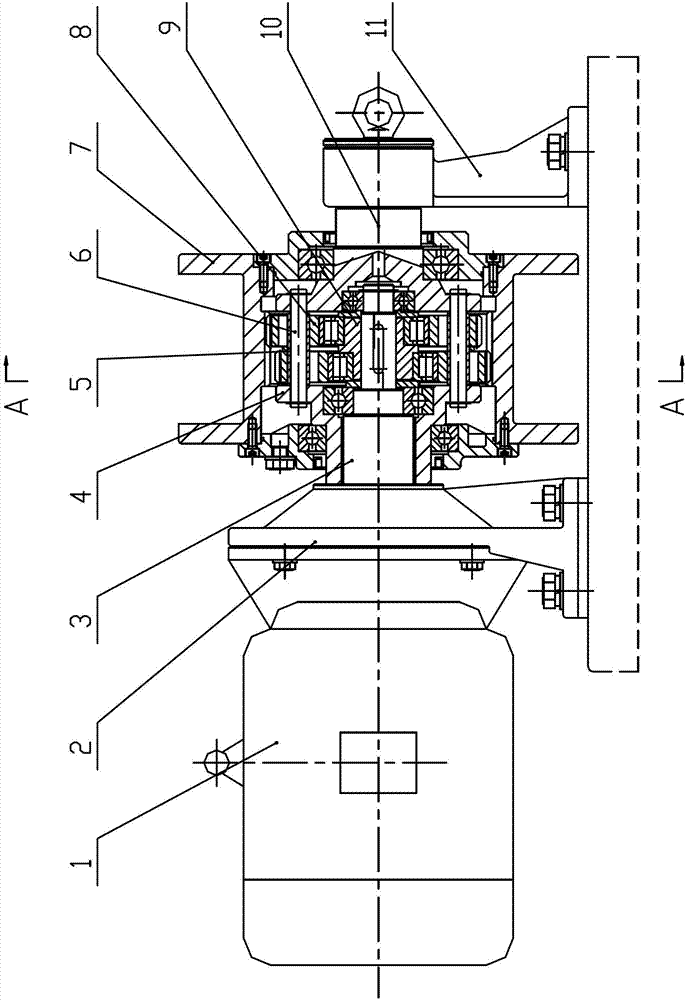

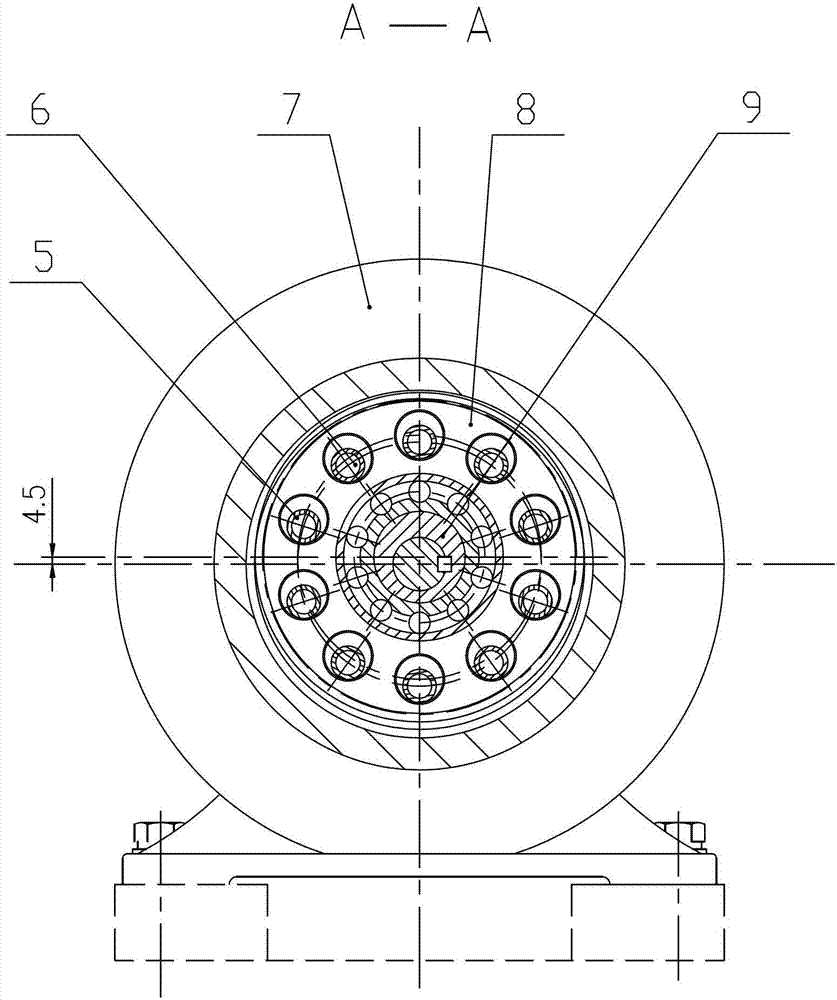

[0015] Such as figure 1 As shown, the reducer of the mixer hoist includes: brake motor 1, input shaft 3, eccentric sleeve 9, left arm 4, right arm 10, pin shaft 6, planetary wheel 8, rope wheel (internal gear) 7 , Pin sleeve 5. The brake motor 1 is connected to the input shaft 3 through a spline shaft to transmit power, and an eccentric sleeve 9 with a displacement of 180 degrees is installed on the input shaft 3. δ( figure 2 The shown δ is 4.5mm), the size of δ is equal to the center distance a between the rope wheel (internal gear) 7 and the planetary wheel 8 meshing, that is: δ=a], two symmetrical ball bearings are installed on the eccentric sleeve 9, and the two The two planetary wheels 8 are mounted symmetrically on the outer rings of the two ball bearings to form an H mechanism (eccentric mechanism). The power drives the H mechanism to rotate through the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com