Mechanism for locking special-shaped part with tooth surface inclined block

A technology for tightening special-shaped and parts, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc. It can solve the problems of low machining accuracy, difficulty in providing clamping force, and difficult quality control of parts, so as to achieve strong processing versatility and prevent deformation Or loosening, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

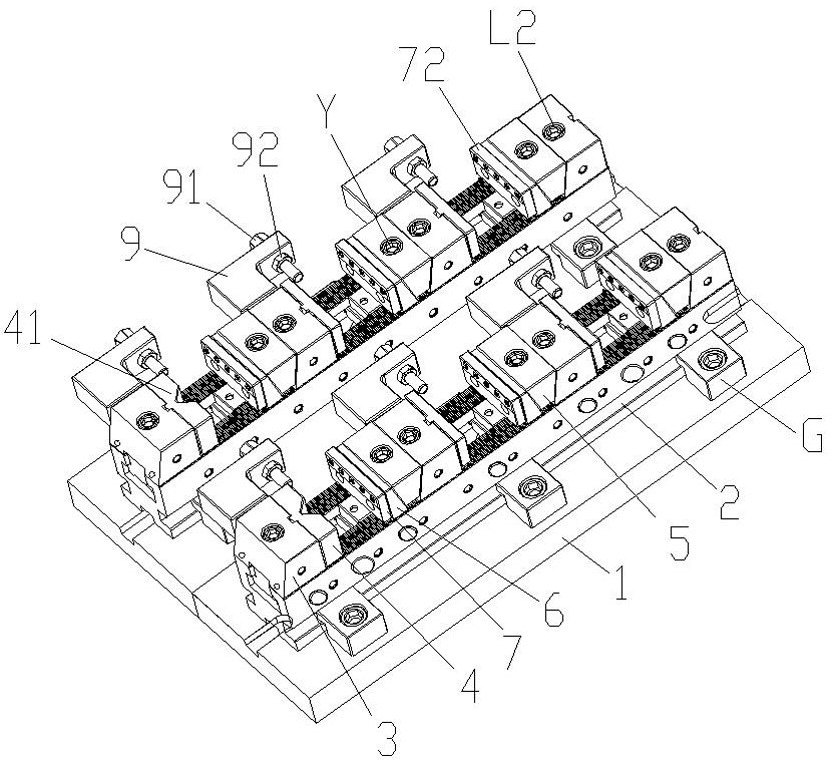

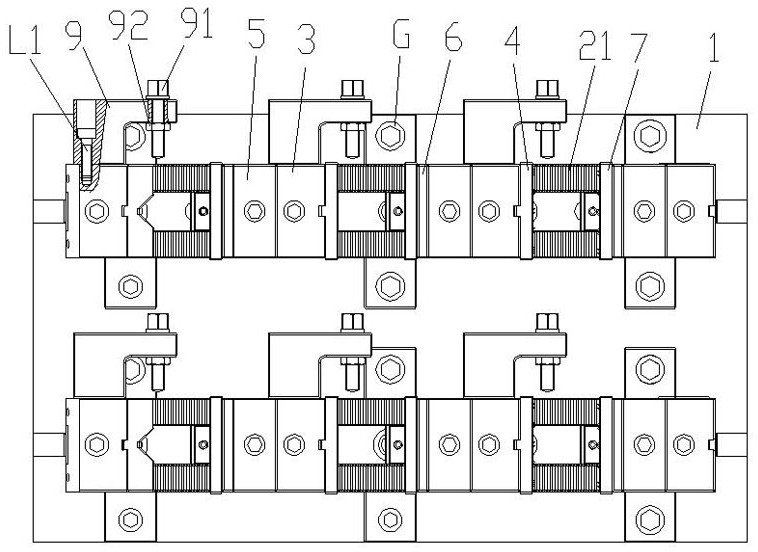

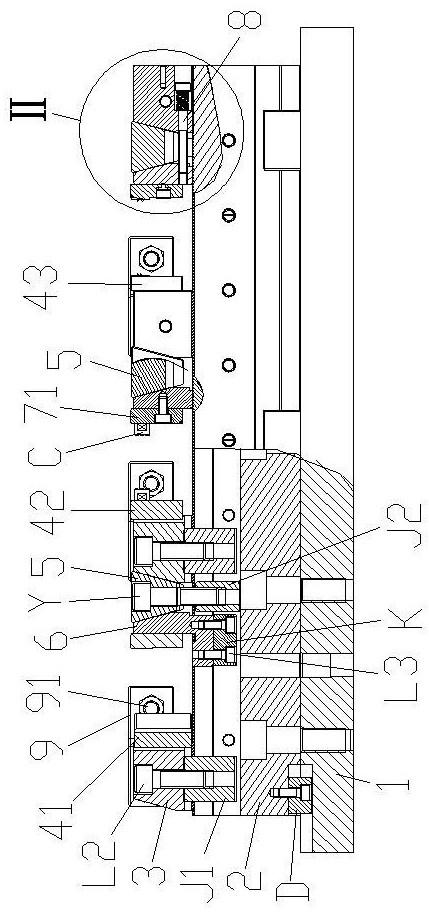

[0049] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0050] Figures 1 to 26 It is a structural representation of the present invention.

[0051]The reference signs are: tooth surface screw block C, positioning key D, tooth block F, clamping block G, inverted T-shaped locking key J1, inverted T-shaped positioning key J2, tensioning block K, side bolt L1, fixed Seat screw L2, tension bolt L3, compression stud Y, base 1, block screw hole 1a, lower positioning slot 1c, fixture body 2, inverted T-shaped slot 2a, buckle slot 2b upper positioning slot 2c, toothed Surface 21, inclined surface fixing seat 3, step hole 3a, fixing seat counterbore 3b, threaded hole 3c, positioning groove 3d, inclined plate surface 31, anti-slip tooth surface 32, clamping and fixing block 4, special-shaped groove 41a, positioning convex strip 4d, special-shaped clamping and fixing block 41, smooth surface clamping and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com