Forming and generating gear milling machine and processing method

A processing method and technology of a gear milling machine, which are applied in the directions of gear cutting machines, metal processing equipment, gear tooth manufacturing tools, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

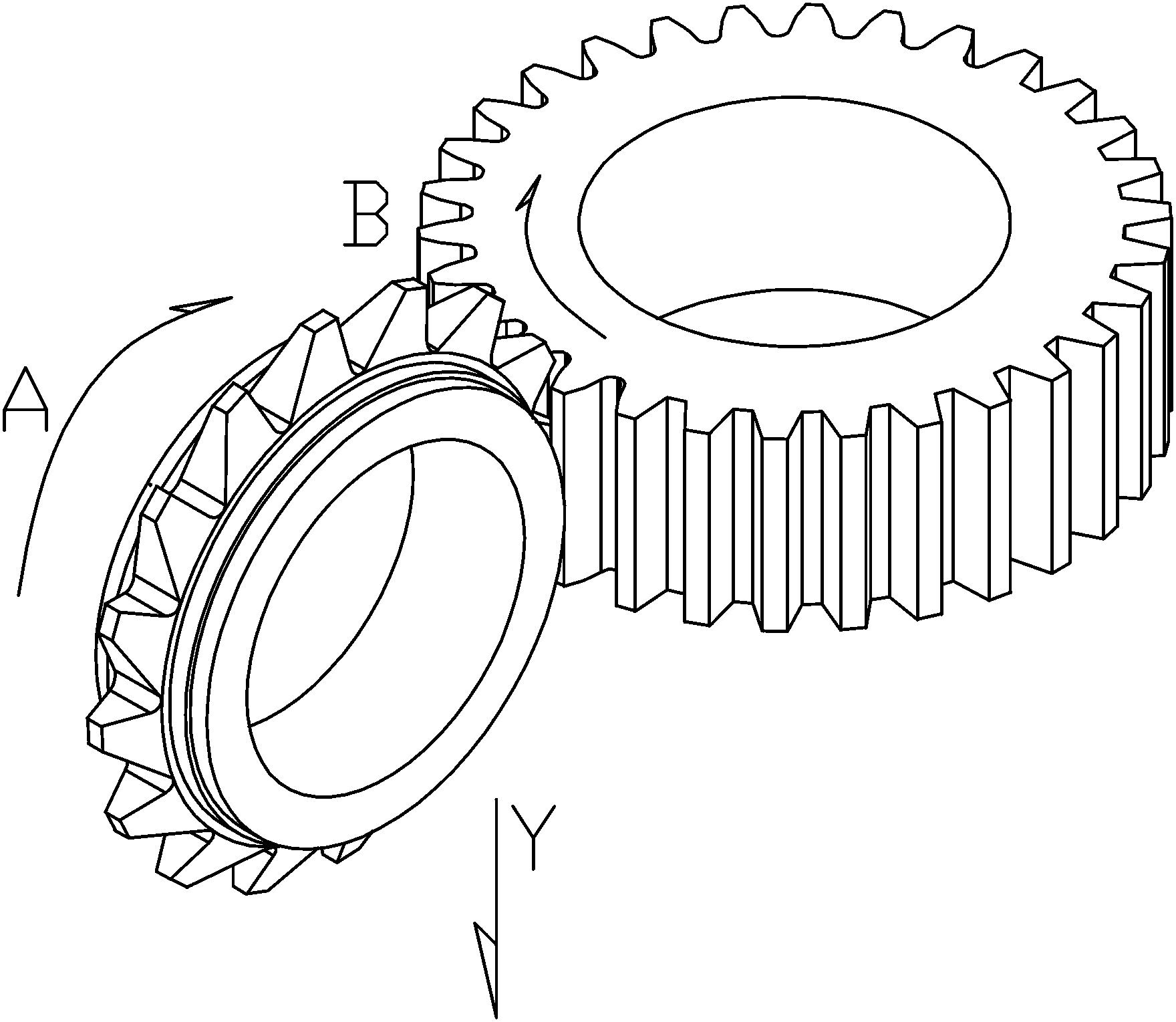

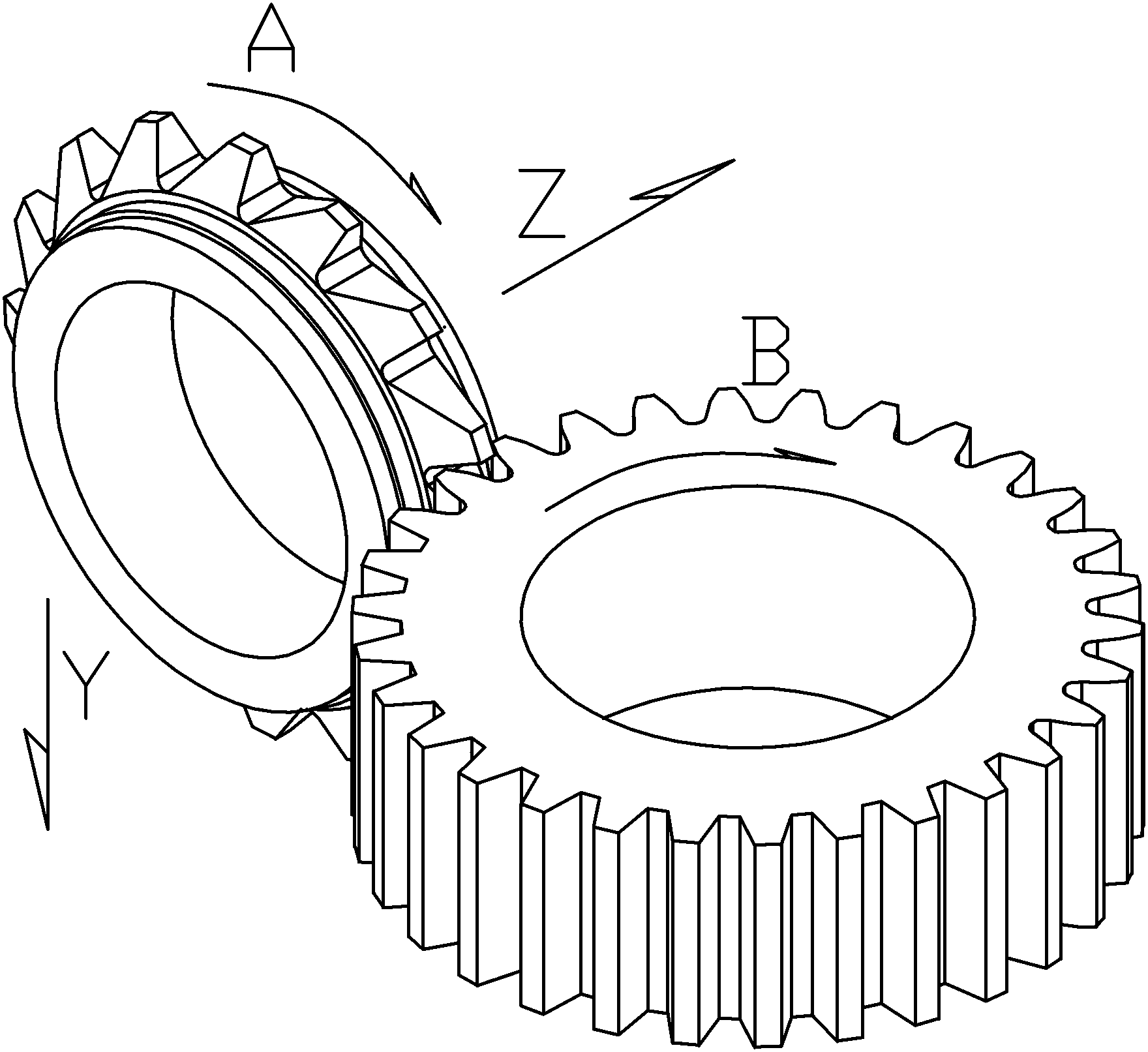

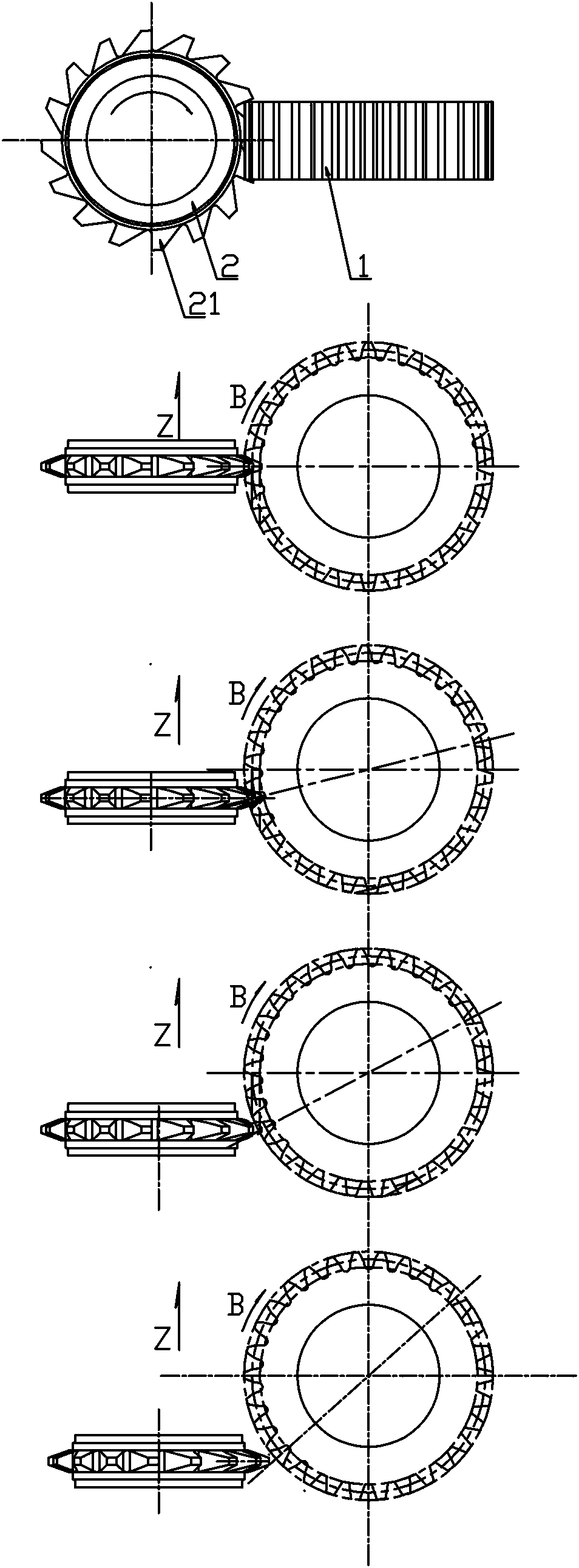

[0031] Such as Figure 4 Among them, a forming and generating gear milling machine includes a machine base 4, on which a rotary table 3 for supporting a workpiece 1 is arranged, and the rotary table 3 drives the workpiece 1 to achieve precise indexing.

[0032] The base 4 is also equipped with an X-direction sliding seat 5 through a slide rail, and the movement of the X-direction sliding seat 5 can realize different full-tooth deep cuttings by controlling the feed position of the X coordinate according to different modulus.

[0033] The X-direction slide seat 5 is fixedly connected with a column 6, and the column 6 is installed with a Y-direction slide seat 7 through a slide rail, and a Z-direction slide seat 9 is installed on the Y-direction slide seat 7 through a slide rail. Y coordinate movement. This movement enables an infeed in the direction of the tooth width for cogging.

[0034] The cutter assembly is installed on the Z-direction slide seat 9. The Z-coordinate move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com