Water-based fracturing fluid thickener and method for preparing same

A water-based fracturing and thickening agent technology, applied in the field of fracturing fluid, can solve the problems of complex fracturing fluid preparation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

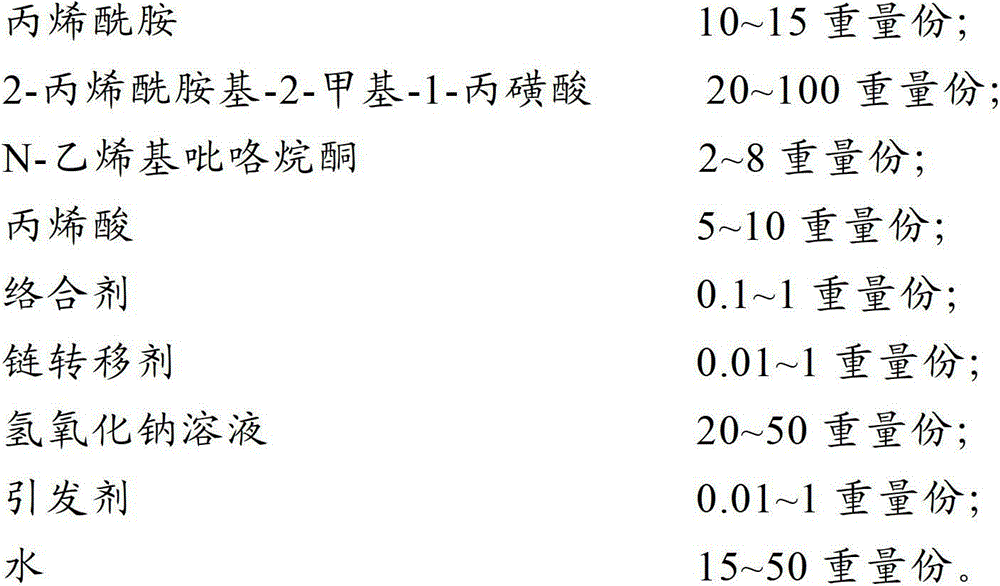

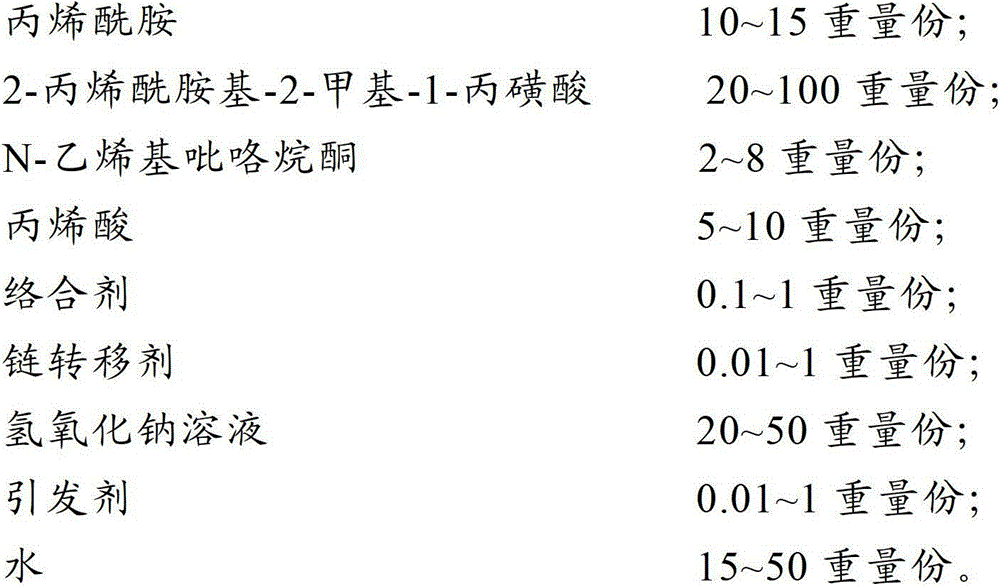

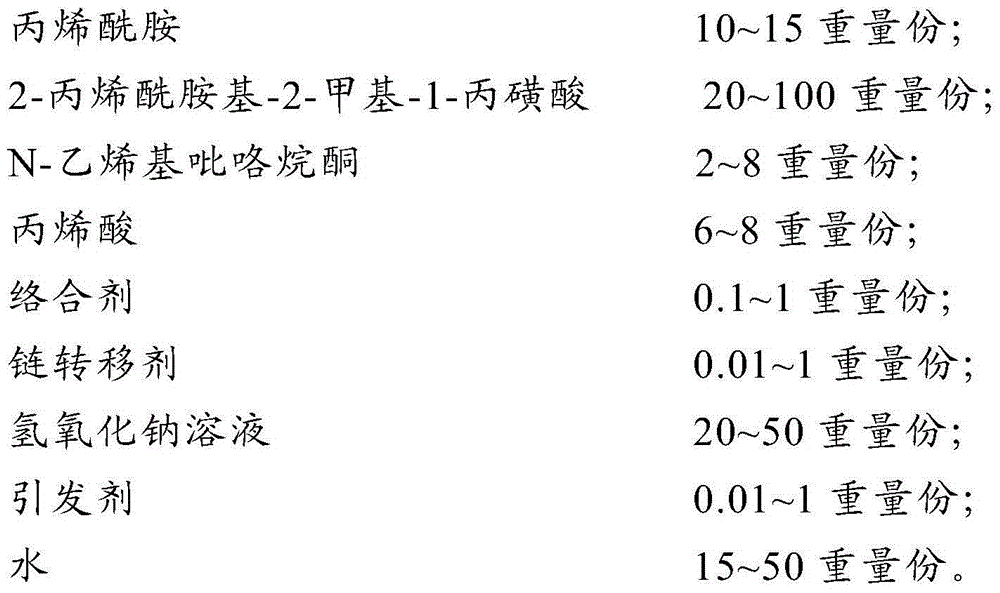

[0027] The present invention also provides a kind of preparation method of water-based fracturing fluid thickener, comprises the following steps:

[0028] Mix 20-100 parts by weight of 2-acrylamido-2-methyl-1-propanesulfonic acid, 15-50 parts by weight of water, 5-10 parts by weight of acrylic acid and sodium hydroxide solution, and adjust the pH to 3 ~11, the first mixed solution was obtained;

[0029] Mixing the first mixed solution, 10-15 parts by weight of acrylamide, 0.1-1 part by weight of a complexing agent and 0.01-1 part by weight of a chain transfer agent to obtain a second mixed solution;

[0030] Mix the second mixed solution, 2-8 parts by weight of N-vinylpyrrolidone, and 0.01-1 part by weight of an initiator, and react to obtain a water-based fracturing fluid thickener.

[0031] In the process of preparing the water-based fracturing fluid thickener, the present invention mainly adopts the copolymerization of acrylamide, 2-acrylamide-2-methyl-1-propanesulfonic ac...

Embodiment 1

[0036]In 20 parts by weight of 2-acrylamido-2-methyl-1-propanesulfonic acid, add 15 parts by weight of deionized water, 5 parts by weight of acrylic acid, and then add a 5% aqueous solution of sodium hydroxide to adjust When the pH reaches 3, add 10 parts by weight of acrylamide, 0.1 parts by weight of complexing agent EDTA, and 0.01 parts by weight of chain transfer agent isopropanol, stir at a temperature of 30°C, and add 2 parts by weight of N-vinylpyrrolidone and 0.01 parts by weight of potassium persulfate were reacted for 12 hours to obtain a water-based fracturing fluid thickener.

Embodiment 2

[0038] In 50 parts by weight of 2-acrylamido-2-methyl-1-propanesulfonic acid, add 30 parts by weight of deionized water, 10 parts by weight of acrylic acid, and then add a weight fraction of 8% sodium hydroxide aqueous solution and pH to 7, then add 10 parts by weight of acrylamide, 0.5 parts by weight of complexing agent EDTA, and 0.1 parts by weight of chain transfer agent isopropanol, stir at a temperature of 45 ° C, and add 5 parts by weight after nitrogen gas flow for 30 minutes N-vinylpyrrolidone and 0.1 parts by weight of ammonium persulfate were reacted for 8 hours to obtain a water-based fracturing fluid thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com