Camshaft decompressor

A decompression device and camshaft technology, applied in the direction of valve devices, engine components, machines/engines, etc., can solve the problems of reverse operation of the operating handle, injury to the operator, and difficulty in operating the diesel engine, so as to achieve simple operation and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

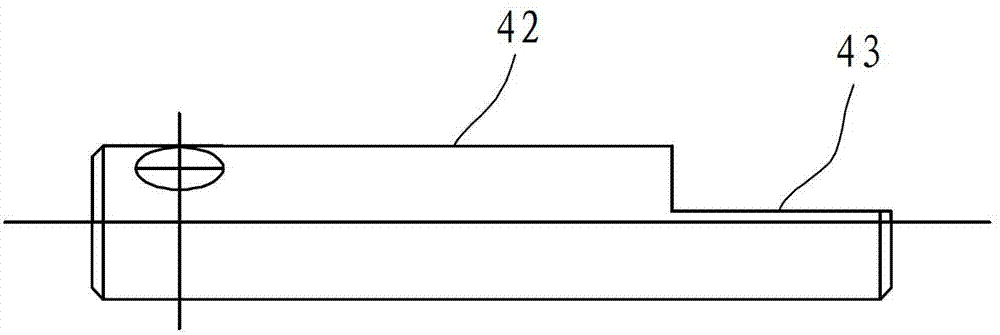

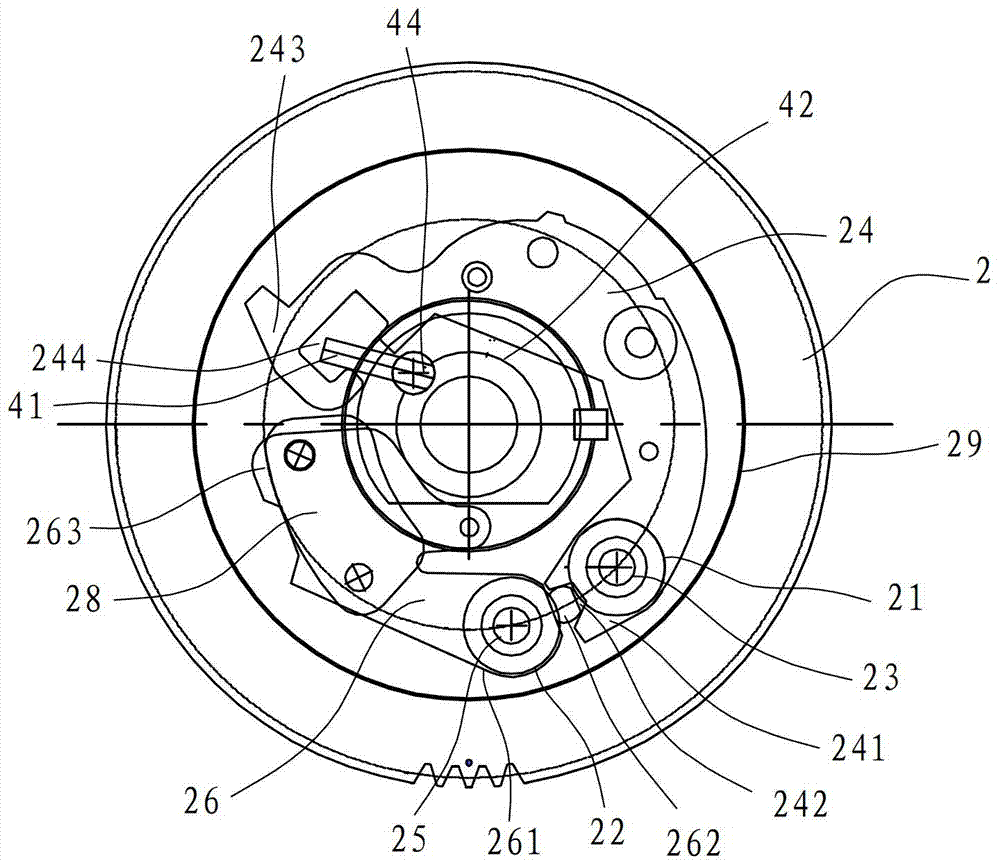

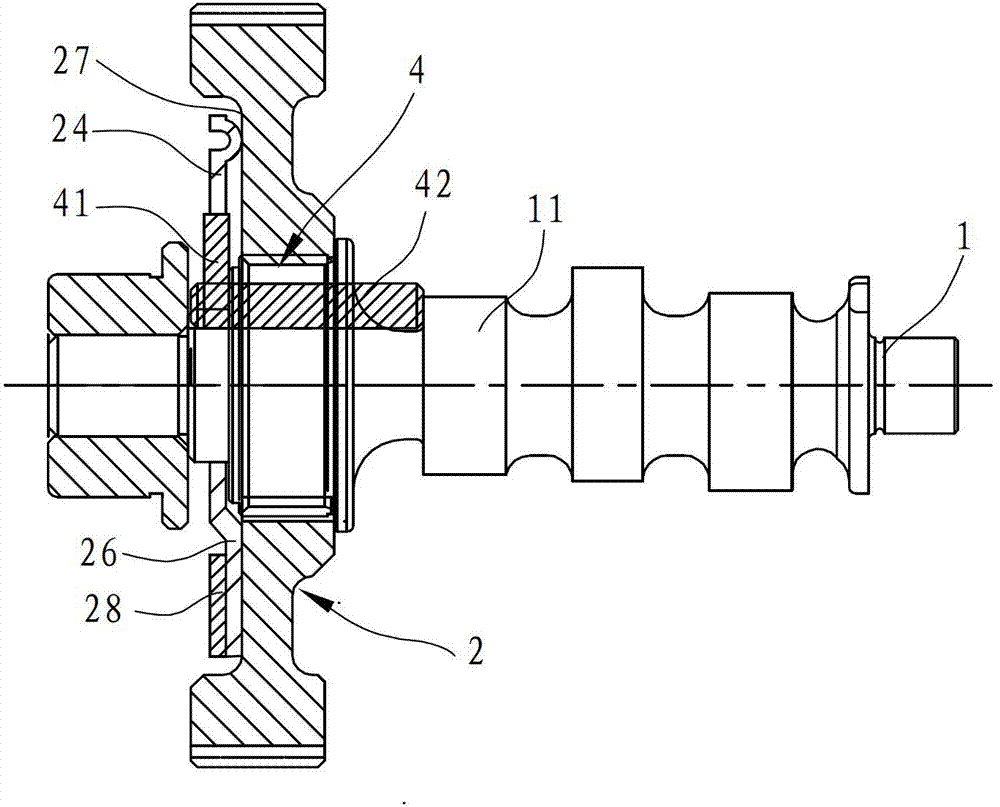

[0015] see figure 1 and figure 2 , a camshaft decompression device, including a camshaft 1, a timing gear 2 sleeved on the camshaft 1, and a bush 3 fixed to the end of the camshaft 1, the bush 3 is located outside the timing gear 2.

[0016] The timing gear 2 is provided with two positioning holes, namely a first positioning hole 21 and a second positioning hole 22 . The first positioning hole 21 is provided with a first flying weight pin 23, through which the first flying weight pin 23 is hinged with the first flying weight 24, and the second positioning hole 22 is provided with a second flying weight pin 25, through which the second flying weight The pin 25 is hinged with a second flying mass 26 . The outer side of the timing gear 2 has a concave surface 27 , and the first flying weight 24 and the second flying weight 26 are both located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com