Multifunctional rail measuring system and method thereof

A measurement system and multi-functional technology, which is applied in the directions of measuring device, measuring inclination, surveying and navigation, etc., can solve the problems of lack of scanning measurement of rail surface contour and low accuracy of track direction measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

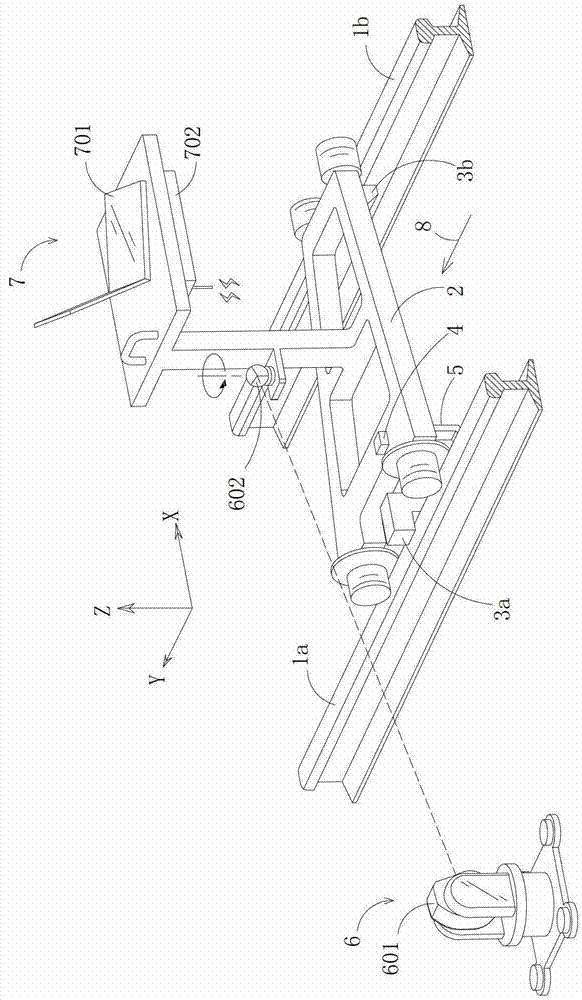

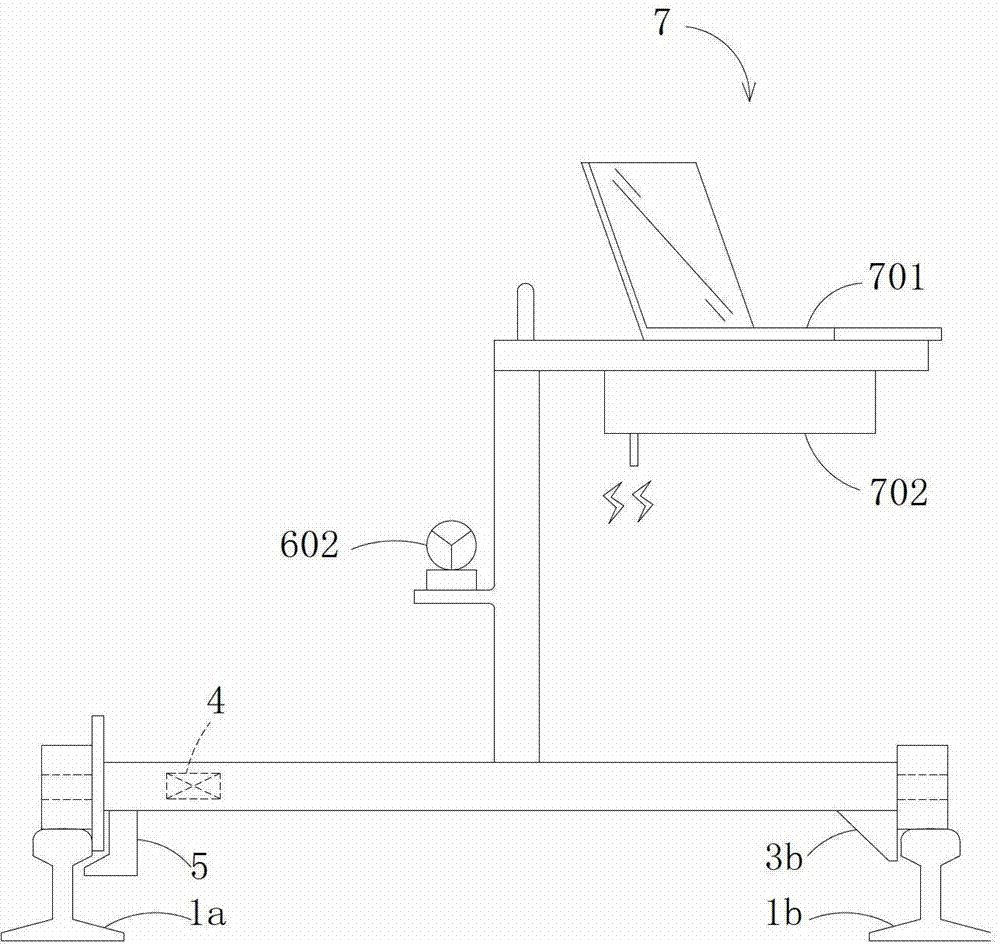

[0024] First of all, the terms "front", "rear", "left" and "right" in the present invention are all based on the relationship of the drawings. Among them, such as figure 1As shown, in the coordinate system defined by the X-axis, Y-axis and Z-axis, the Y-axis direction corresponds to the terms "front" and "rear", and the X-axis direction corresponds to the terms "left" and "right".

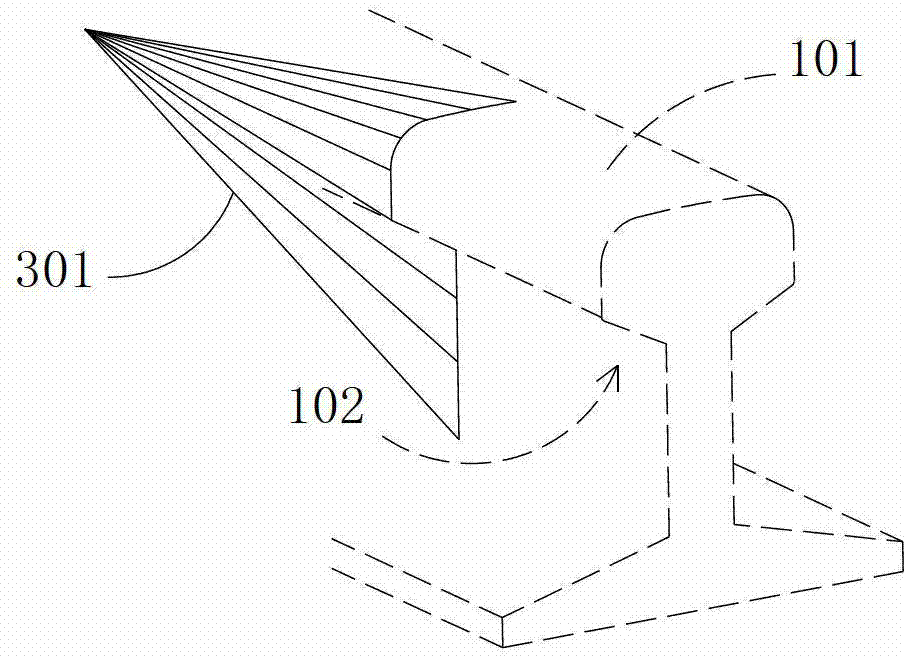

[0025] Such as figure 1 , 2 As shown, the car body of the rail car 2 is a structure with a wide left and a narrow right. The front and rear ends of the left side of the rail car 2 are respectively provided with wheels with rims. Because the magnetic element 5 applies a magnetic force to the inner side of the left rail 1a, the rims of the two wheels on the left side of the rail car 2 are close to the inner wall of the rail head of the left rail 1a, and the laser three-dimensional contour scanning device 3a on the left rail side is located at these two ends. Between the magnetic elements 5; the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com