Coating thickness gauge and coating thickness testing method

A technology of coating thickness and thickness gauge, applied in the direction of electric/magnetic thickness measurement, instruments, measuring devices, etc., can solve the problems affecting the performance indicators of the instrument, achieve the effect of improving measurement stability, improving stability, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

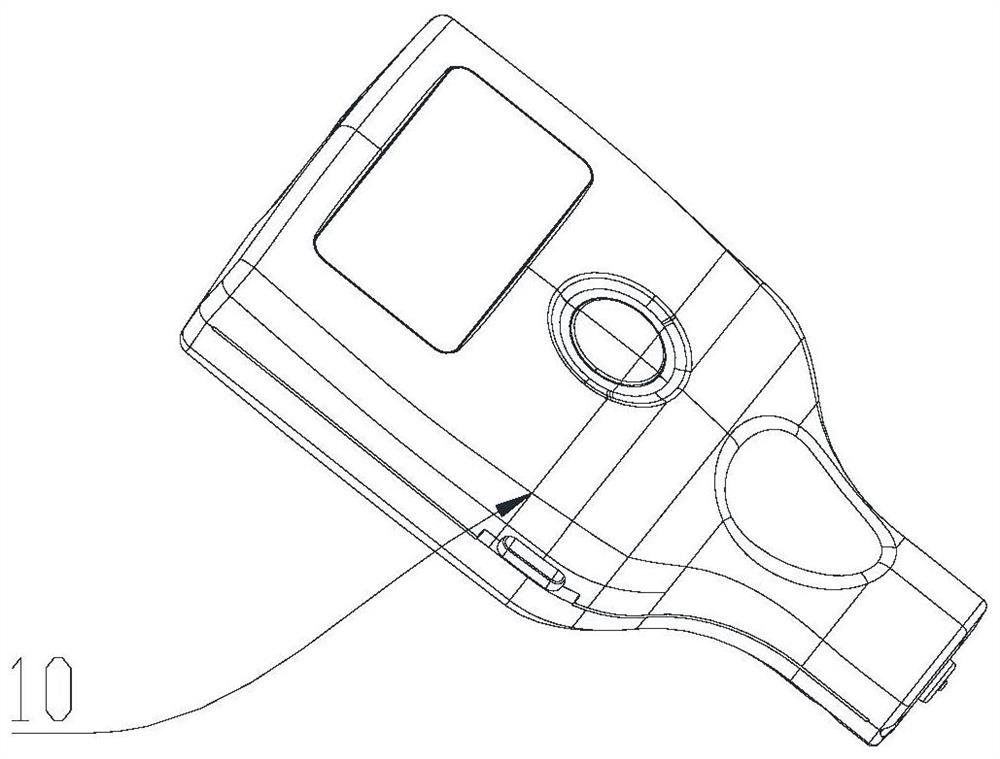

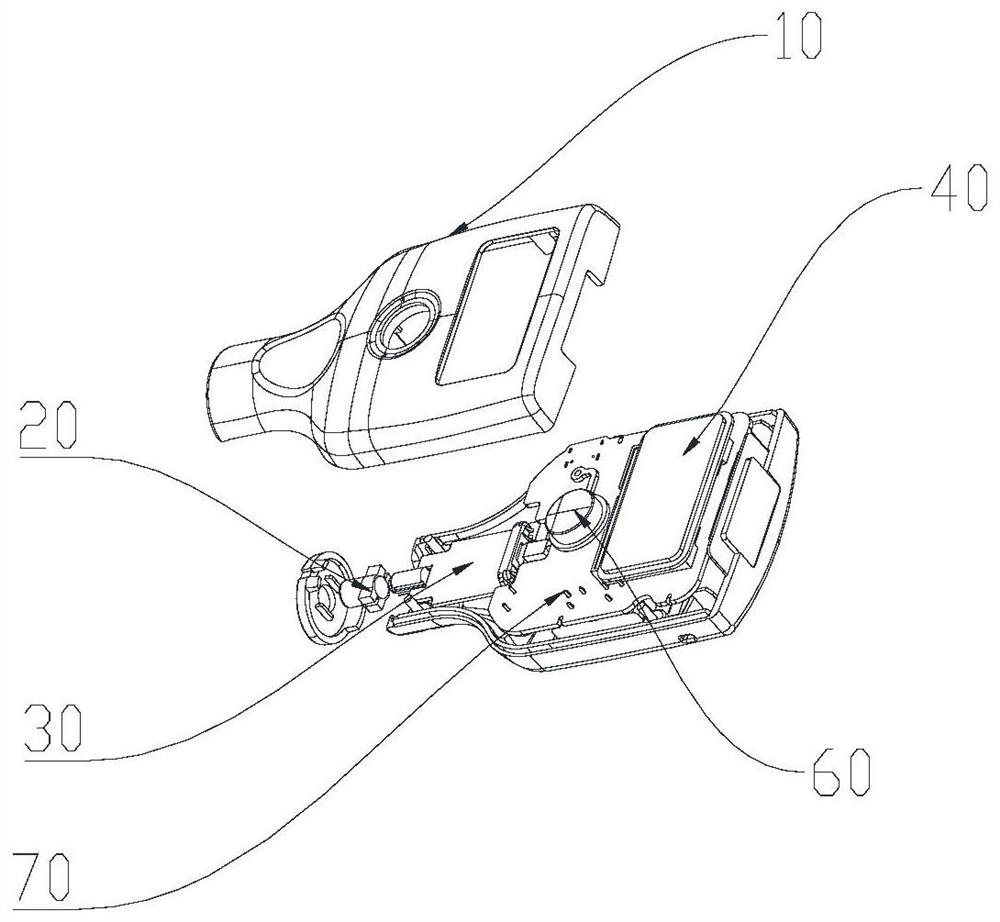

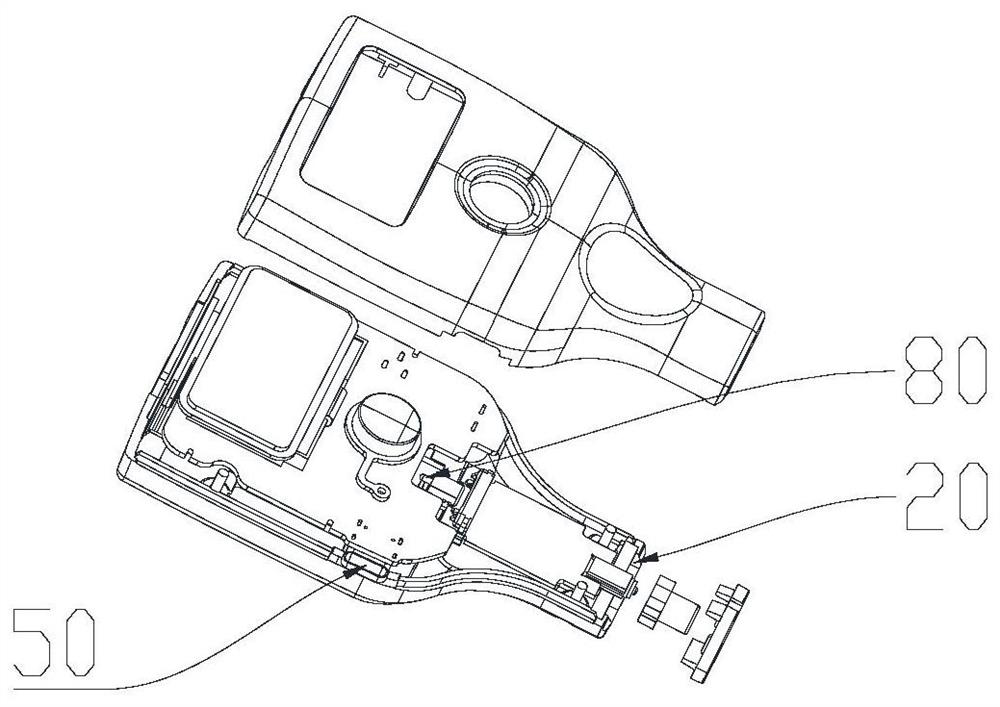

[0046] The housing 10 is used to install each part; the housing 10 has an installation space inside;

[0050] The display screen 40 is used to display the measured value; the display screen 40 is arranged on the housing 10;

[0052] A battery is used to supply power to each part; the battery is arranged in the installation space;

[0054] The main circuit board 70 is used to process each signal; the main circuit board 70 is arranged in the housing 10, and is respectively connected with the

[0056] The inner wall of the housing 10 is provided with a positioning groove corresponding to the auxiliary circuit board 30, and a positioning block is provided in the positioning groove.

[0057] The detection coil 23 and the excitation coil 22 are wound on the same iron core 24. When the iron core 24 is in contact with the coating, the detection head

[0058] As shown in Figure 5, in the embodiment of the present application, the secondary circuit board includes: a D / A converter U3, an amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com