Whole course tracking method and whole course tracking system of discrete manufacturing workshop production process quality

A technology for discrete manufacturing workshops and production processes, applied in the field of full traceability of the production process quality of discrete manufacturing workshops, can solve problems such as backward information collection methods, difficulties in product or finished product quality traceability, and scattered quality information, so as to achieve information management and improve The pass rate of one off-line and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

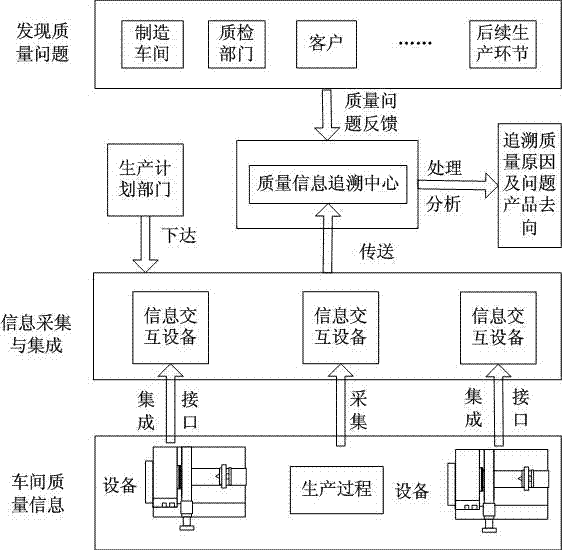

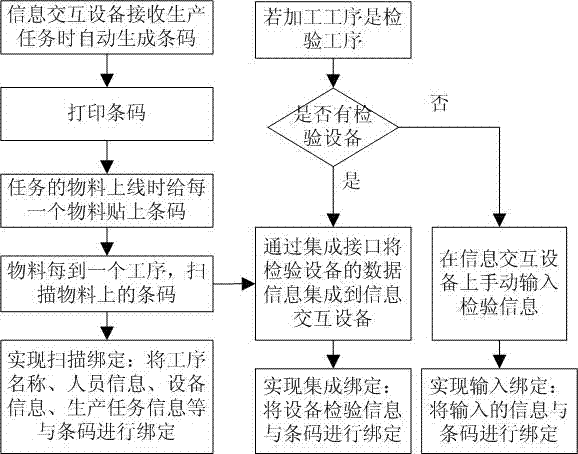

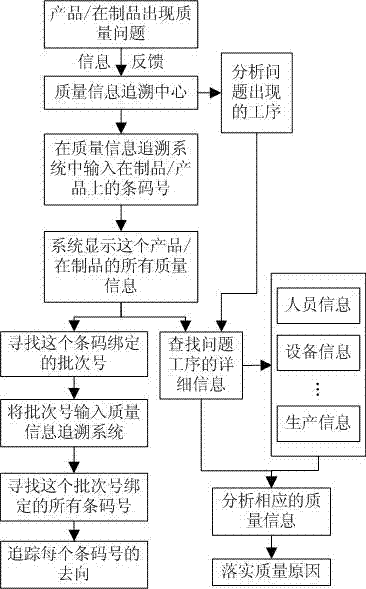

[0021] figure 1 It is a technical framework diagram of the present invention. like figure 1 Shown: The whole process quality traceability method and system of the discrete manufacturing workshop include information interaction equipment, quality information collection and management software, workshop quality information integration interface, barcode printing device, barcode scanning device, quality information traceability center, etc. The information interaction devices include ordinary computers, tablet computers, smart phones and other devices that have interfaces for integration with other devices and are compatible with quality information collection and management software. They are used to receive production task information issued by the planning management department and collect discrete manufacturing information. Workshop pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com