Mold motor

A motor and molding technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit static parts, etc., can solve the problems such as the inability of the terminal and the lead to conduct, and the terminal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0025] 1. Structure of the molded motor

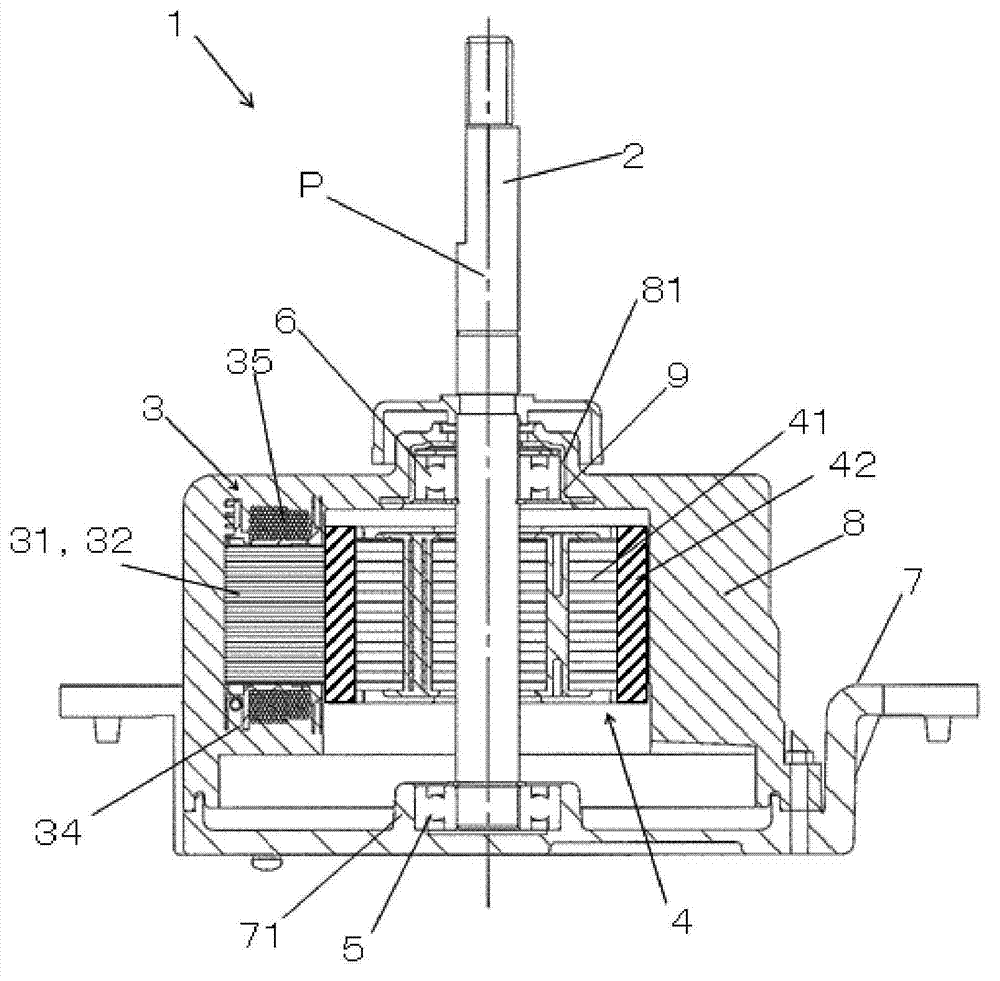

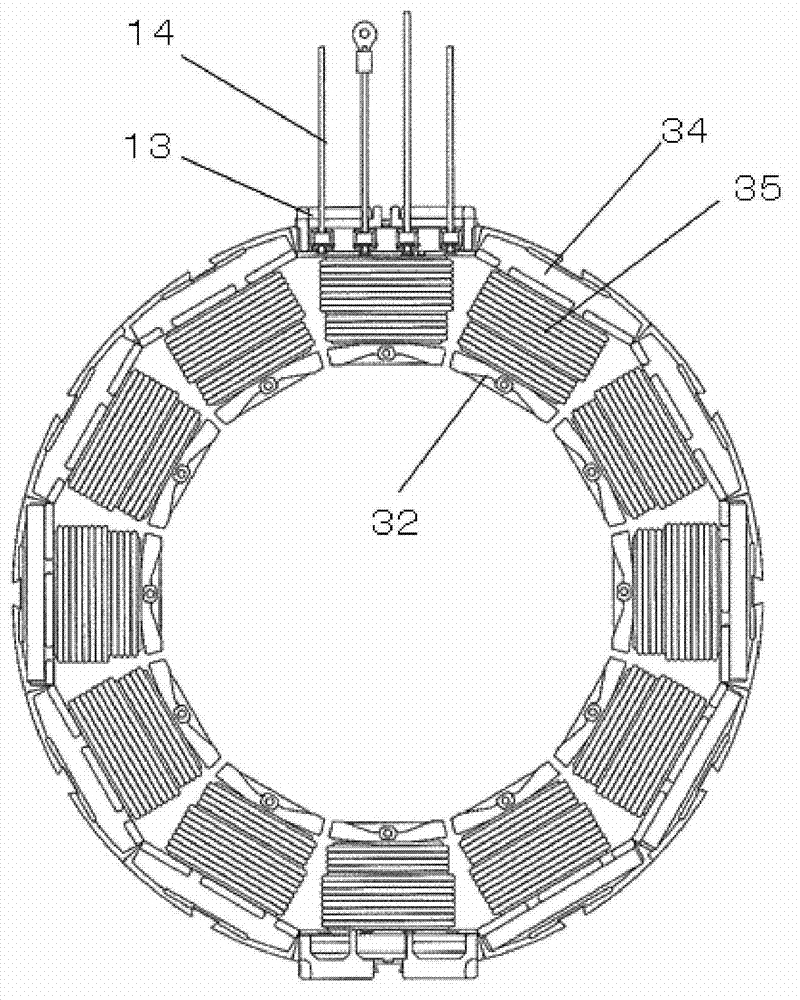

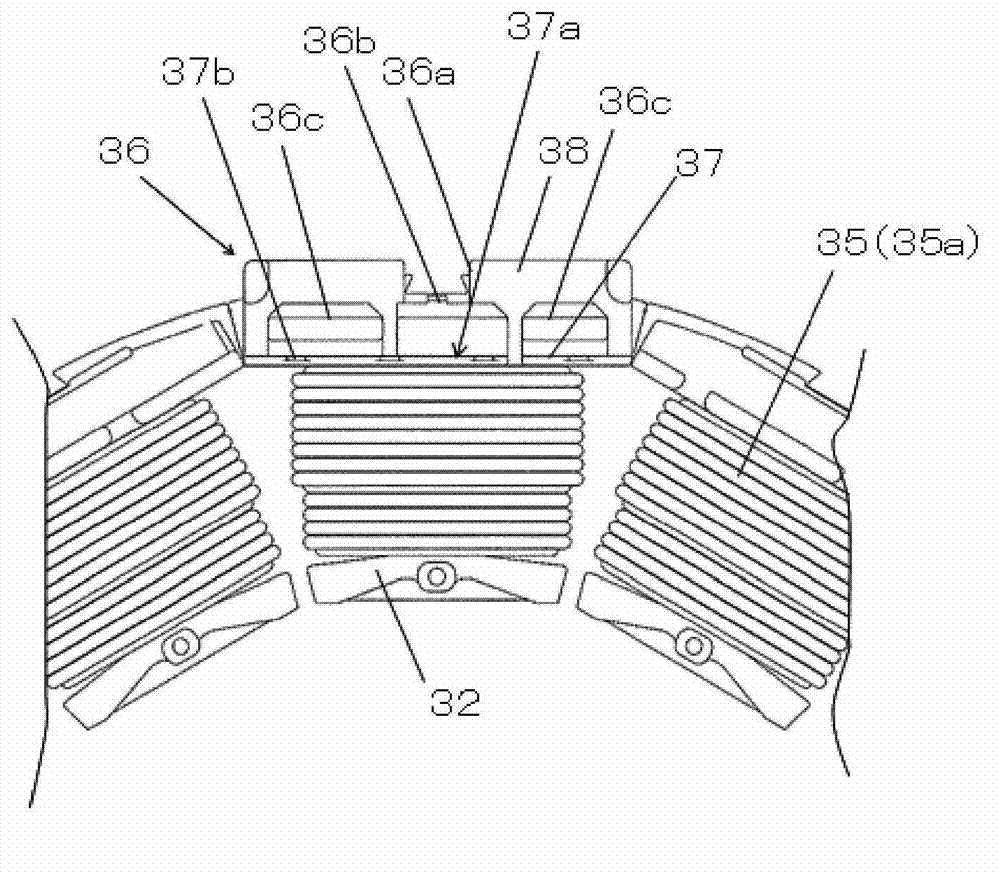

[0026] figure 1 It is a cross-sectional view showing a schematic structure of a molded motor according to an embodiment of the present invention. figure 1 The motor 1 shown is an example of a molded motor of the present invention. figure 2 is a plan view of the stator 3 .

[0027] The motor 1 includes a shaft 2 , a stator 3 , a rotor 4 , a first bearing 5 , a second bearing 6 , a motor bracket 7 , a motor housing 8 and a bearing bracket 9 . One end portion of the shaft 2 is supported by a first bearing 5 , and the central portion is supported by a second bearing 6 . The shaft 2 is rotatable with respect to the first bearing 5 and the second bearing 6 . The other end of the shaft 2 is located outside the motor 1 . The shaft 2 is equipped with a load on the other end side.

[0028] In addition, in figure 1 In , the axis P is a line extending along the center of the shaft 2 . In the following description, the direction along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com