Rear derailleur

A transmission and connecting rod technology, applied in vehicle gearboxes, chain/belt transmissions, transportation and packaging, etc., can solve the problems of user inconvenience, easy to be contaminated with sand, difficult to clean, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

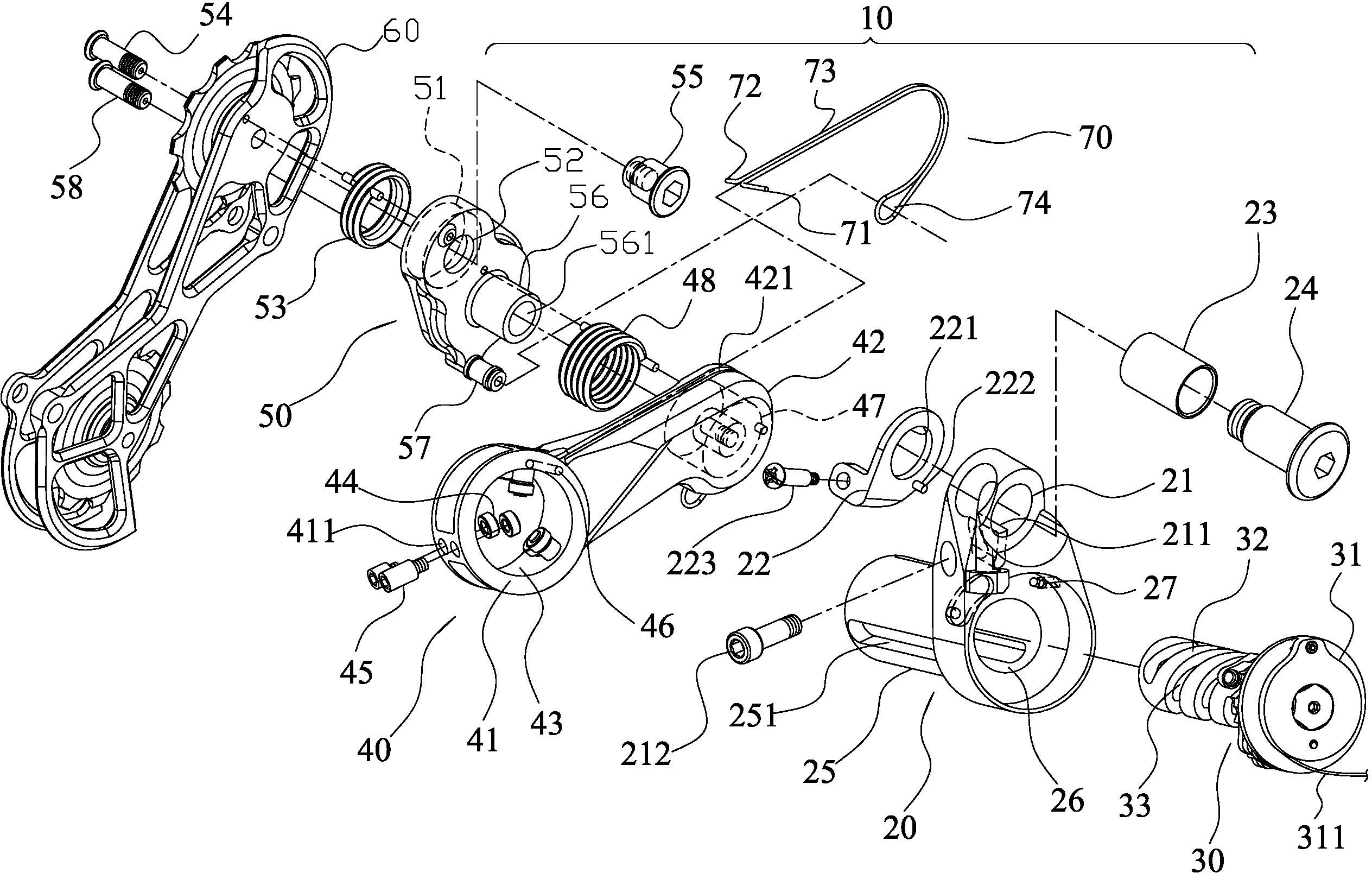

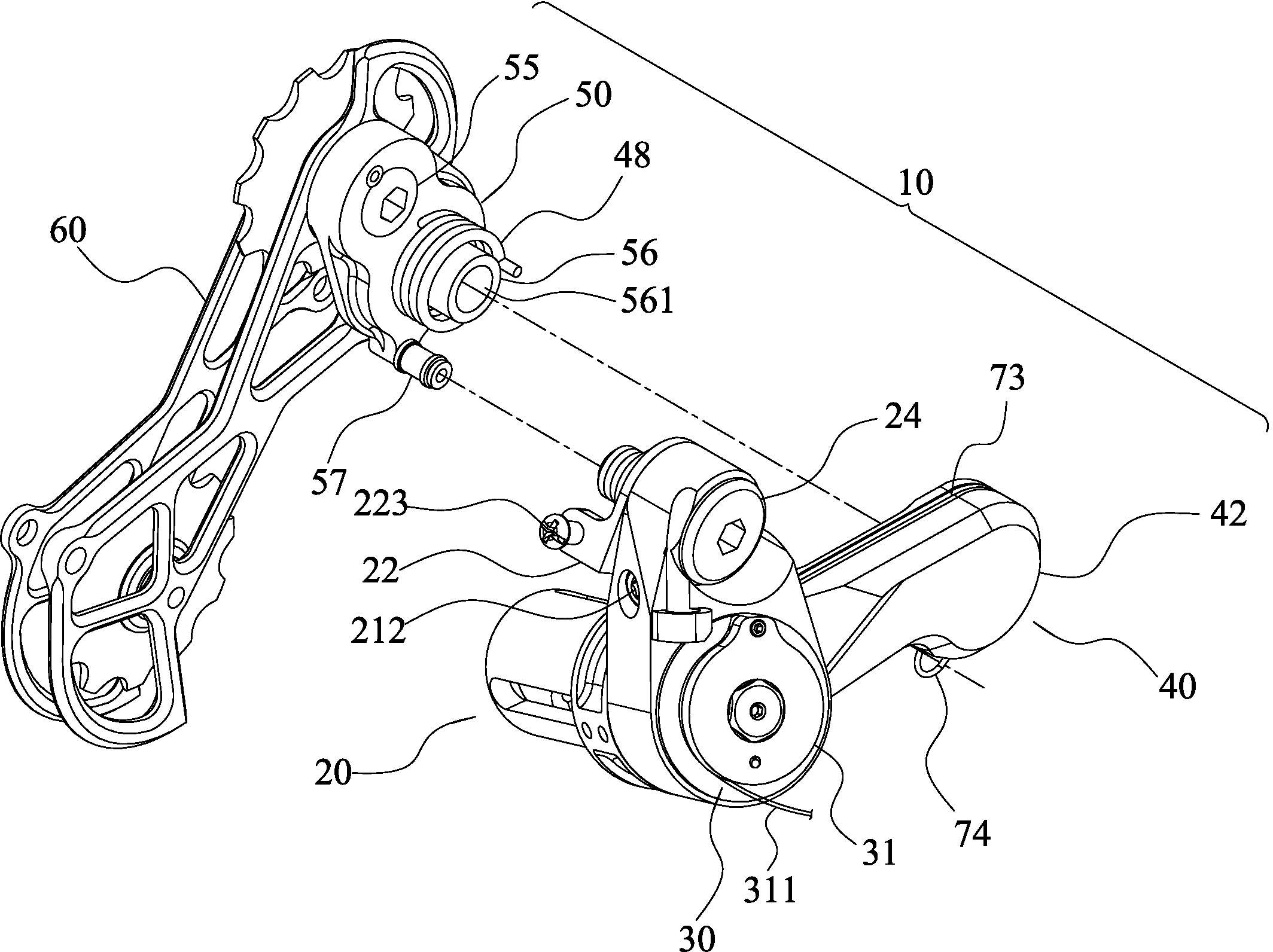

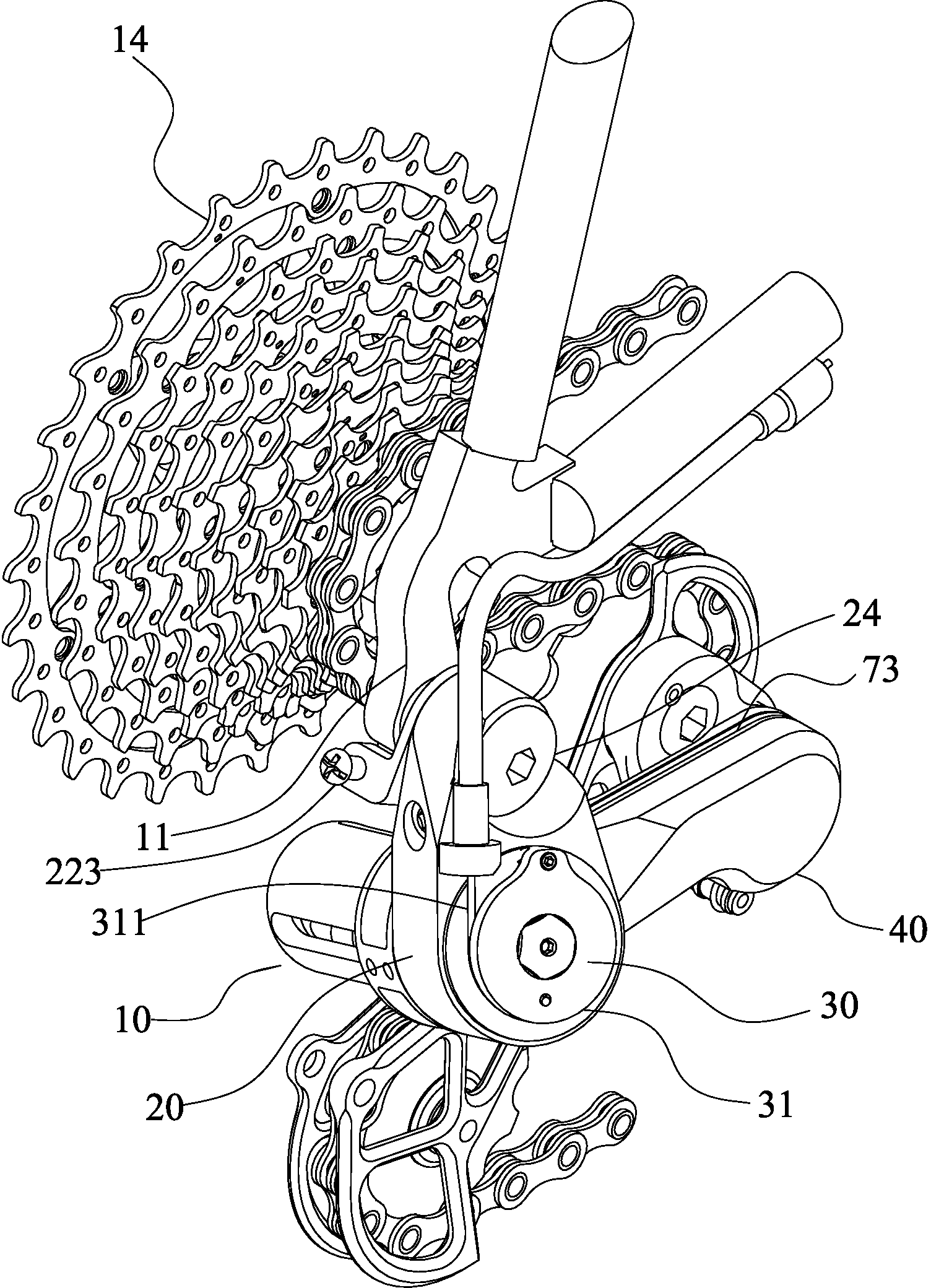

[0055] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0056] A rear derailleur 10 of the present invention, the accompanying drawings illustrate a specific embodiment of the present invention, and among its components, all references to front and rear, left and right, top and bottom, upper and lower, and horizontal and vertical are only It is used for convenience of description, and does not limit the invention, nor restrict its components to any position or orientation in space. The dimensions specified in the drawings and description can be changed according to the design and requirements of the specific embodiments of the present invention without departing from the patent scope of the present invention.

[0057] For the detailed structure of rear derailleur 10 of the present invention, please refer to Figure 1 to Figure 10 As shown, the rear derailleur 10 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com