Pulverized coal burner for pulverized coal collection and concentration, and burning method

A pulverized coal burner and the technology of the burner are applied in the combustion method, the burner for burning powder fuel, the burner, etc., which can solve the problems of large resistance, many wear parts, complex structure, etc., so as to reduce the pressure drop and wear , the effect of low system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

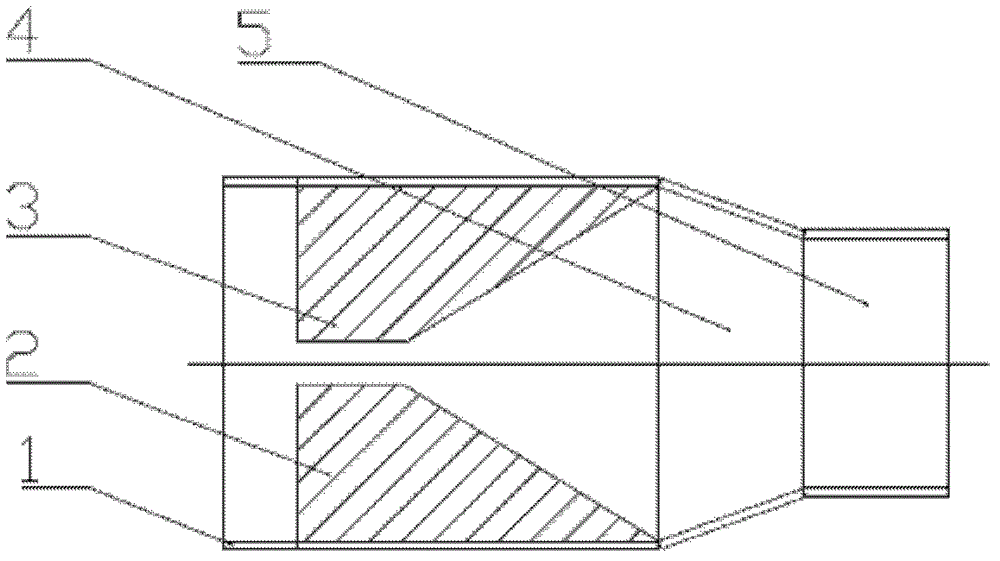

[0026] According to the pulverized coal burner of the invention, the burner includes a nozzle body 1 ; a lower powder collecting flame stabilizer 2 ; an upper powder collecting flame stabilizing device 3 ; a variable diameter conduit 4 ; figure 1 is a sectional view of the burner of the present invention.

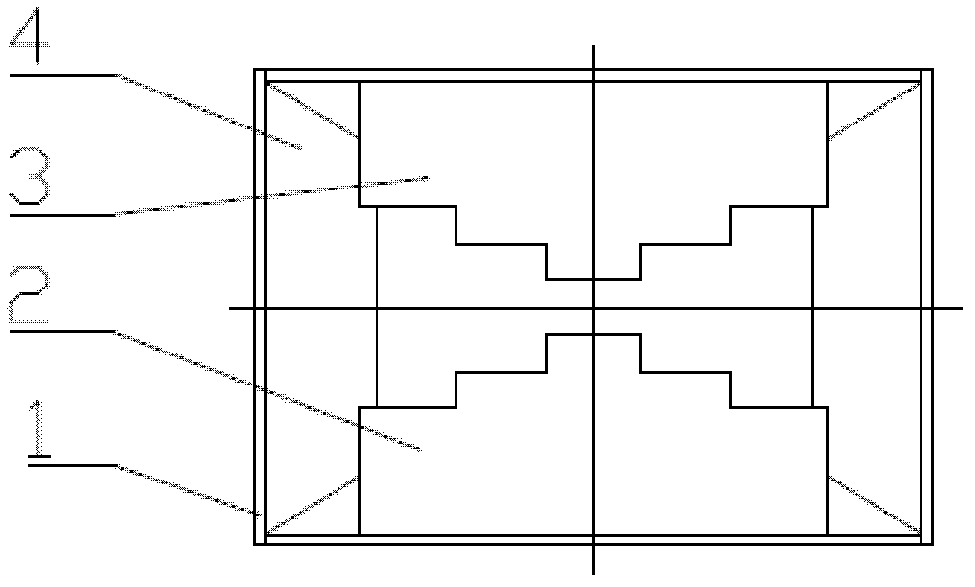

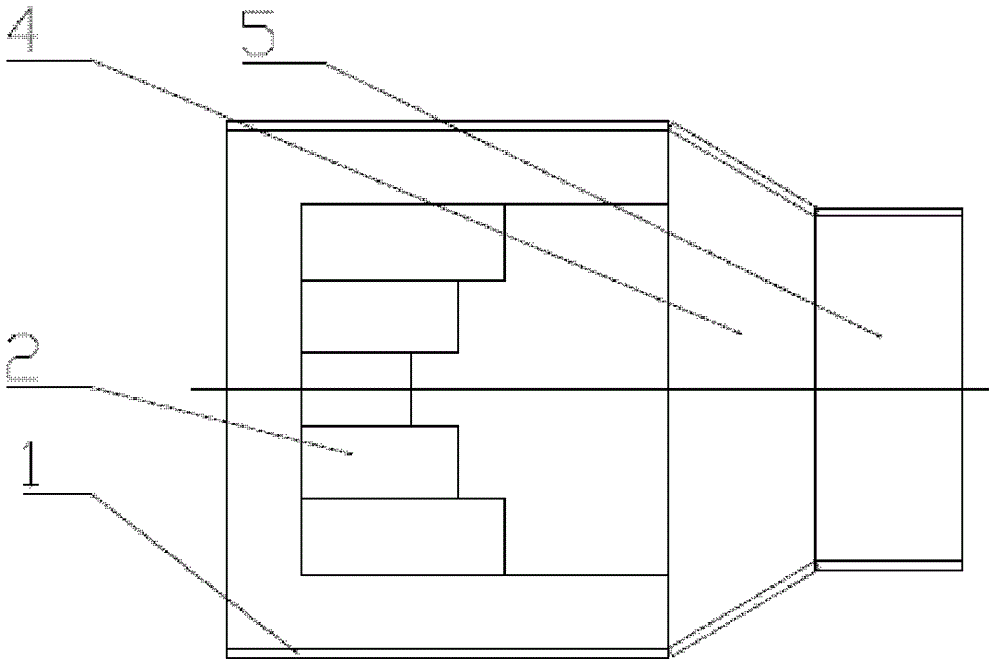

[0027] The lower powder collecting flame stabilizer 2 and the upper powder collecting flame stabilizer 3 are located at the lower and upper parts of the nozzle main body 1 respectively, and the structure of the powder collecting flame stabilizer is shown in the attached figure 2 (burner left view) and attached image 3 (Burner top view sectional view), it is an irregular oblate cone as a whole, one side of the cone is connected to the nozzle main body 1, the side of the cone with a slope faces the inner side of the nozzle main body 1, and the upper and lower two collect powder to stabilize the flame Corresponding to the slope of the device; the front end of the powder col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com