Low inductance power module

A power module and power technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of imprecise and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

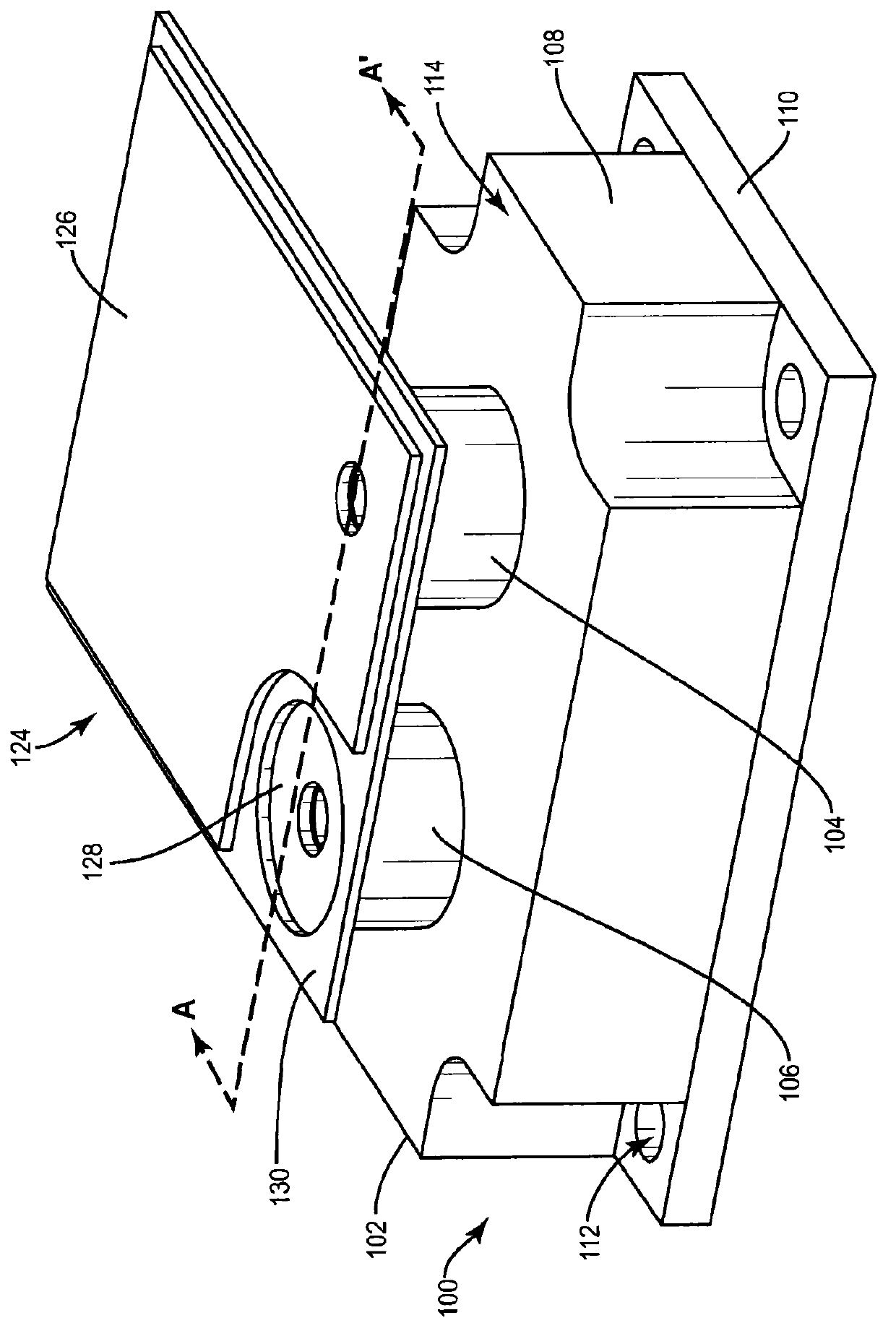

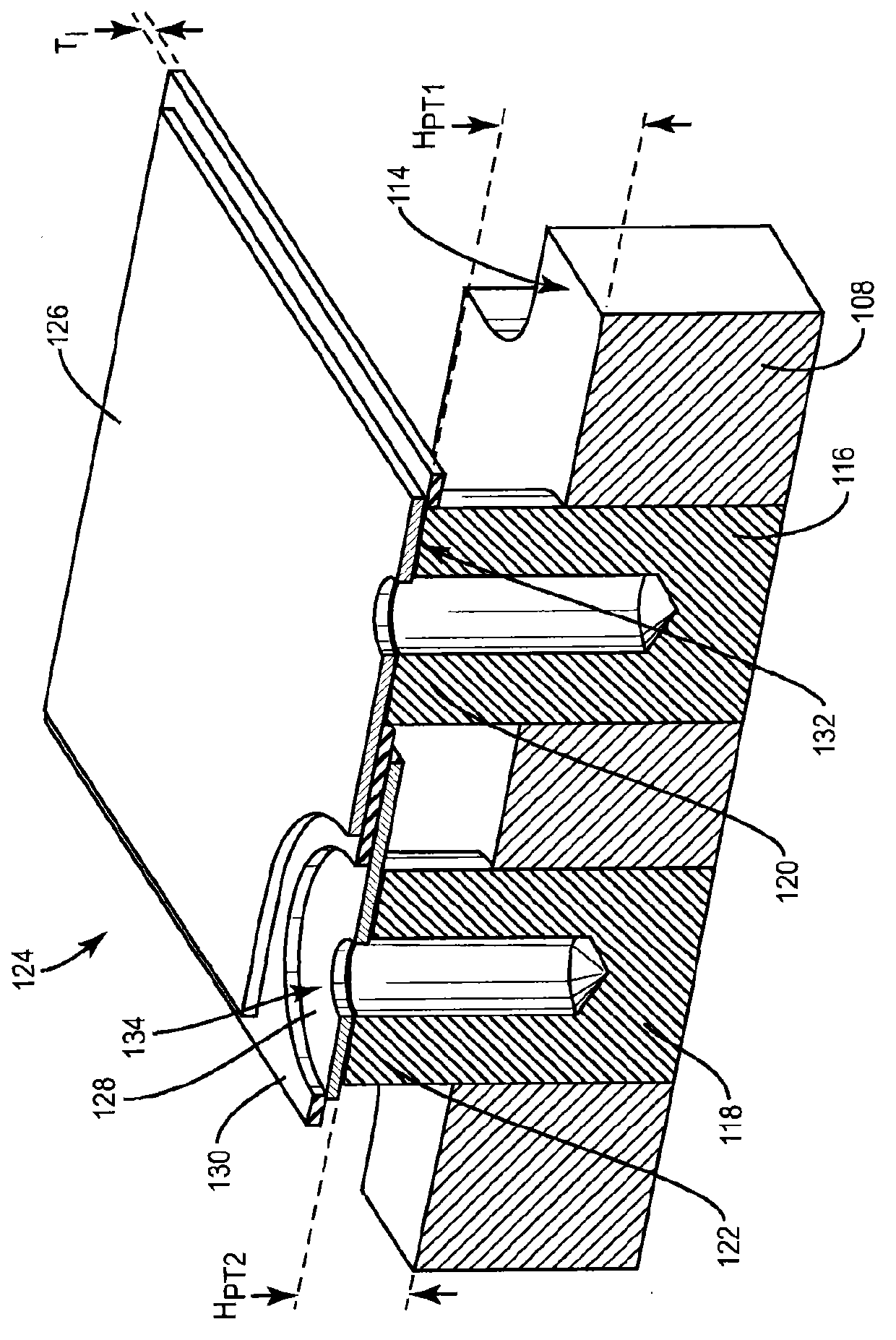

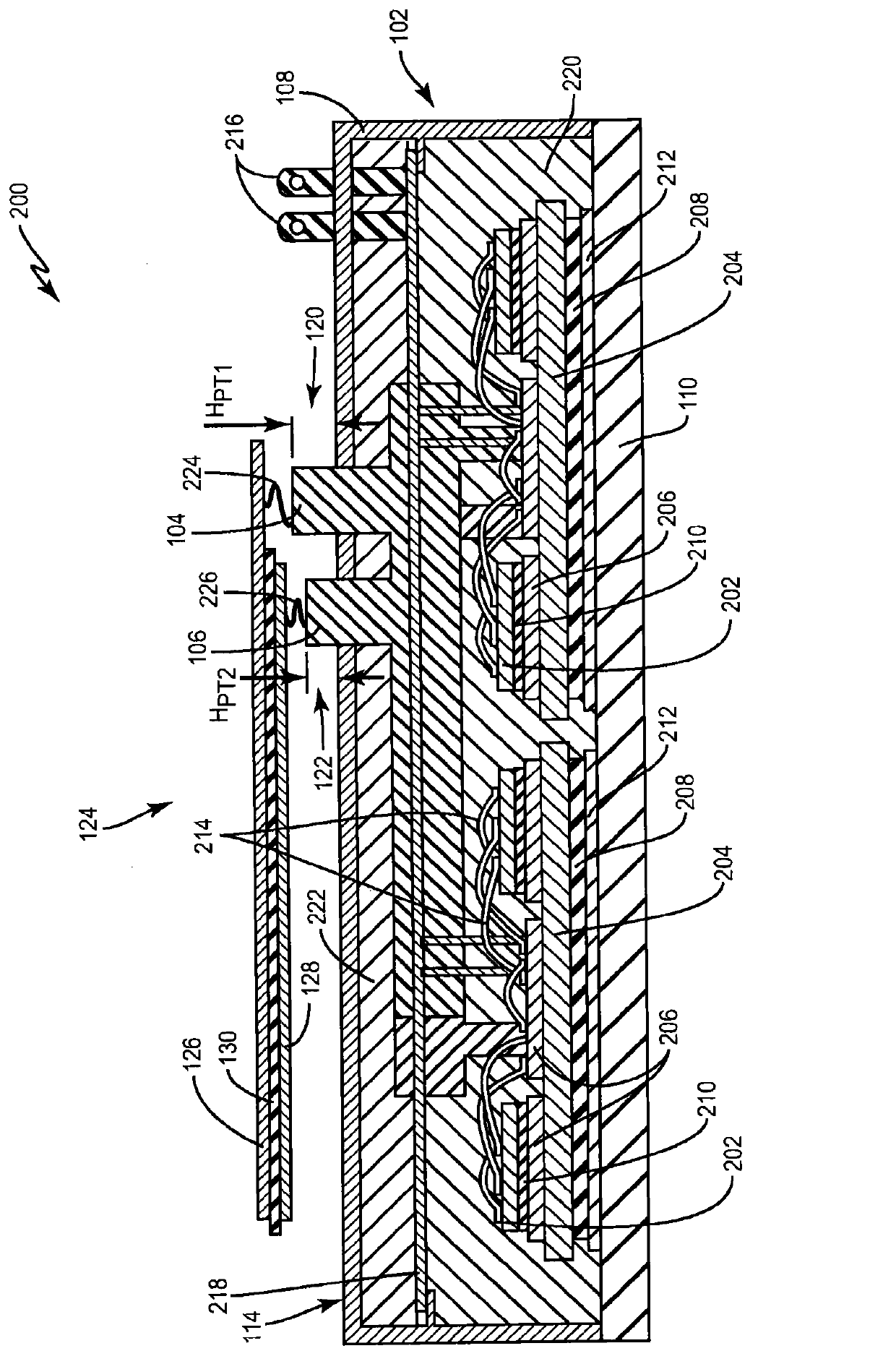

[0014] figure 1 One embodiment of a power module 100 is shown comprising a housing 102 , a power semiconductor die (not visible) enclosed within the housing 102 , a first power terminal 104 and a second power terminal 106 . figure 2 show figure 1 A partial cross-sectional view of the power module 100 shown in , taken along the line marked A-A'. figure 2 Housing 102 and power terminals 104, 106 are shown, but components enclosed by housing 102 are not shown. Exemplary internal components of power module 100 may be described later herein Figure 3-5 was seen in.

[0015] Each power terminal 104 , 106 of the module 100 is embedded in the housing 102 and is electrically connected to a power semiconductor die in the housing 102 . In one embodiment, housing 102 also includes a plastic frame 108 that is attached to metal body 110 . The metal body 110 has a plurality of holes 112 along the periphery for securing the module 100 to, for example, a heating device or other type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com