Laminated porous film, separator for battery, and battery

A porous film and laminated technology, applied in the field of separators for non-aqueous electrolyte batteries, can solve the problems of not being able to be used as electrolytes, and achieve good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0226] With respect to 100 parts by mass of polypropylene-based resin (manufactured by Prime Polymer, Prime Polypro F300SV, MFR: 3.0 g / 10 minutes) as the thermoplastic resin composition (a) constituting the A layer, 3, as a β crystal nucleating agent was added. 0.2 parts by mass of 9-bis[4-(N-cyclohexylcarbamoyl)phenyl]-2,4,8,10-tetraoxaspiro[5.5]undecane, and then use Toshiba Machine Co., Ltd. A co-rotating twin-screw extruder (caliber φ40 mm, L / D: 32) was melt-kneaded at 280° C., processed into pellets, and resin composition A1 was obtained.

[0227] The above-mentioned resin composition A1 was extruded at 200°C by an extruder, extruded from a single-layer T-die, cooled and solidified with a casting roll at 123°C, and a laminated non-porous film with a thickness of 180 μm was obtained.

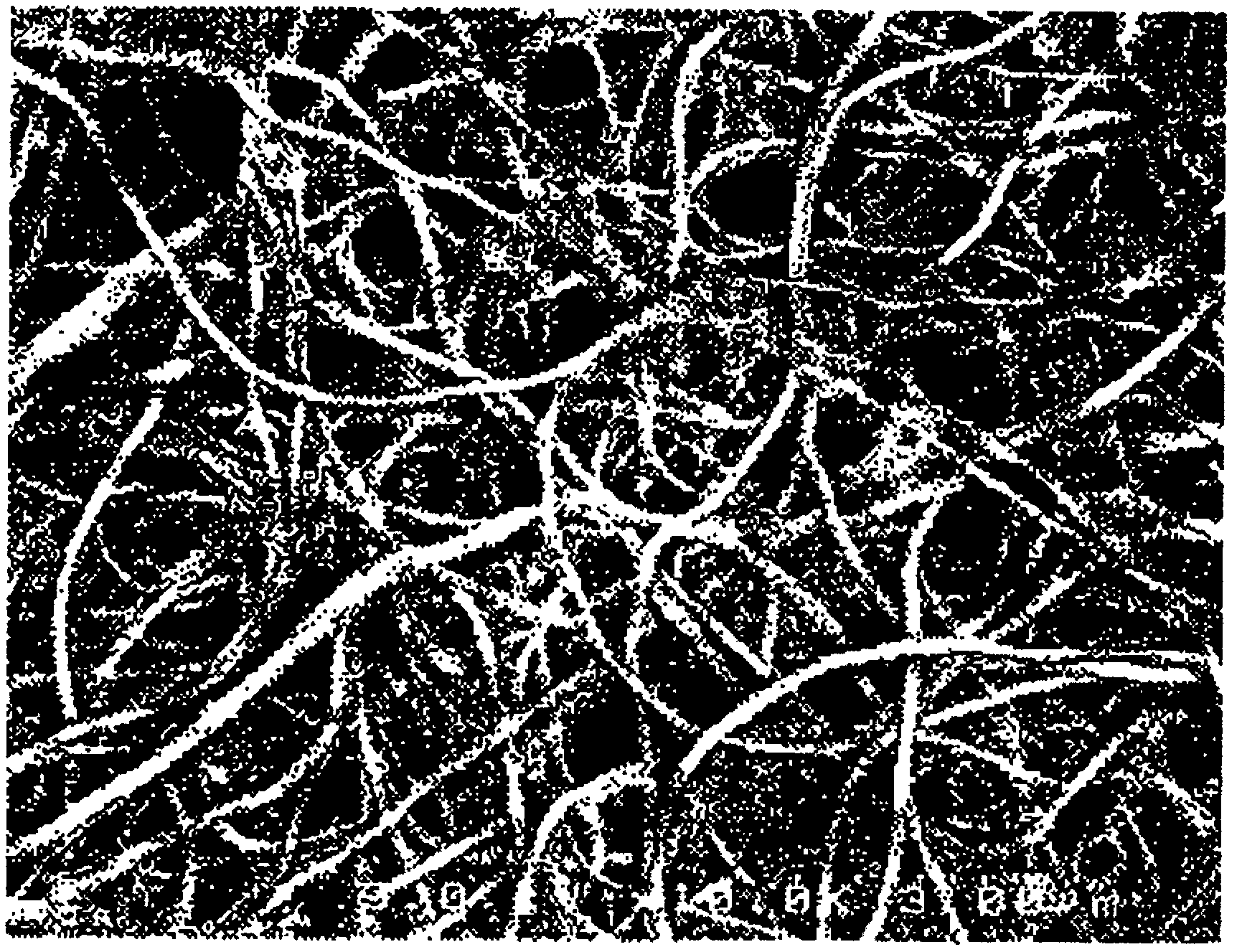

[0228] The above-mentioned laminated non-porous film was stretched to 4.0 times in the longitudinal direction at 10°C to 85°C by using a roll stretching machine, and then stretched to 5.0 ti...

Embodiment 2

[0232] A laminate was produced in the same manner as in Example 1, except that the concentration of the ultra-high molecular weight polyethylene solution was 0.001% by mass for the thermoplastic resin composition (b) constituting the nonwoven fabric layer (layer B). porous membrane.

Embodiment 3

[0234] For the thermoplastic resin composition (b) that constitutes the nonwoven fabric layer (B layer), high-density polyethylene (manufactured by Mitsui Chemicals, HI-ZEX3300F) was selected, and the same method as in Example 1 was made except that laminated porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com