Transport drum for the transverse axial transport of rod-shaped items for the tobacco processing industry

A conveying roller, horizontal and axial technology, applied in the direction of tobacco, application, cigarette manufacturing, etc., can solve the problems of long downtime, time-consuming, etc., and achieve the effect of fast and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

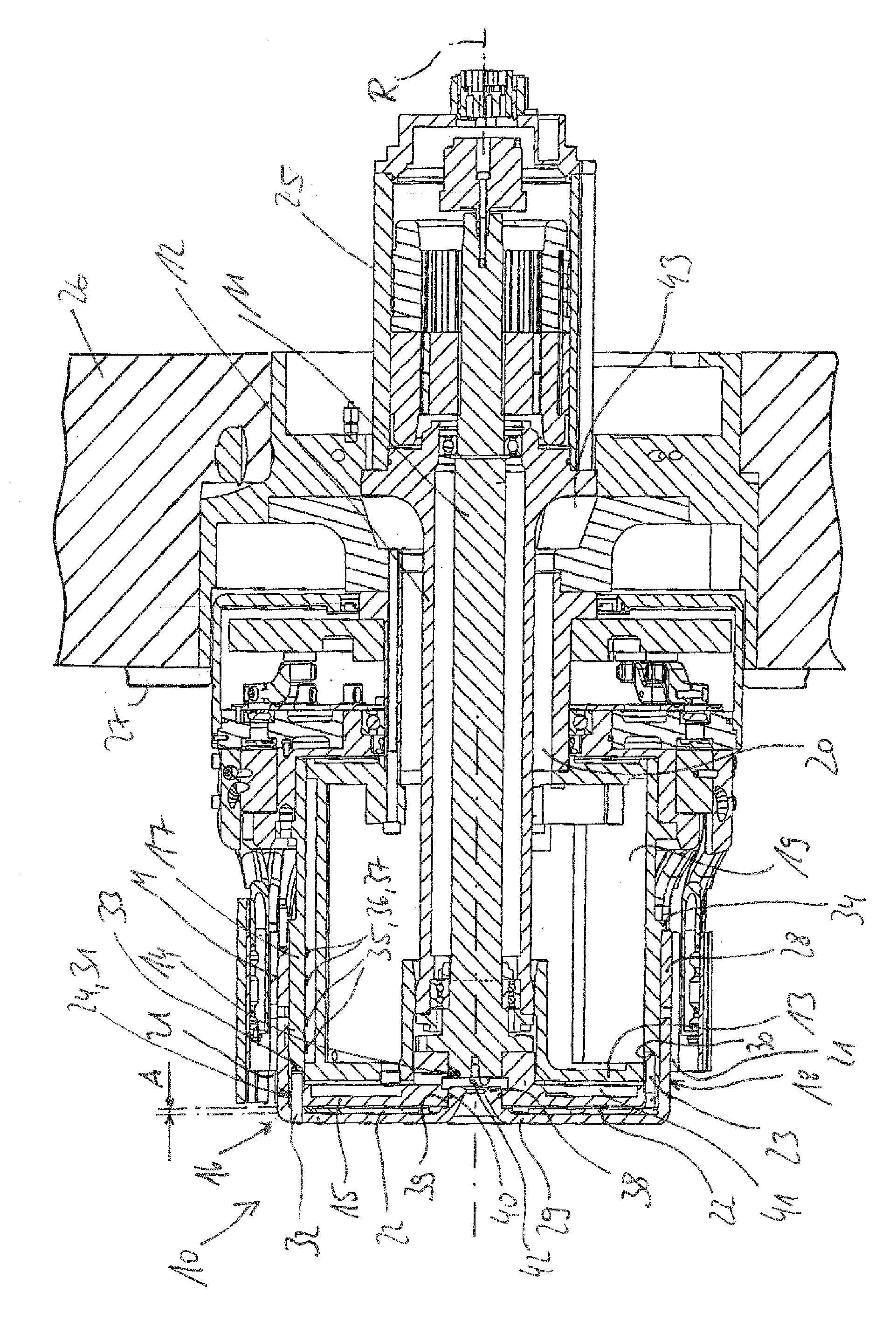

[0021] The invention relates to a conveying roller for transversely conveying rod-shaped products of the tobacco processing industry. The conveying rollers described below are used for conveying filters, cigarettes, filter rods, tobacco rods or similar articles. However, the conveying rollers are of course also suitable for conveying slightly elongated products in the transverse direction, which have a cross-section that is not circular, that is, for example oval, rectangular or triangular.

[0022] Such a conveyor roller 10 generally comprises at least one drive shaft 11 and a roller body 16 assigned to said drive shaft 11 . The drum body 16 has on its outer cover M a receptacle 21 with a suction opening 35 for receiving and holding the rod-shaped product. The vacuum necessary to hold the rod-shaped product can be generated by means of a vacuum supply 43 and can be acted upon at least part of the receptacle 21 via the control flange 13 . The drum body 16 is in operative con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com