Lifting tool special for shaft construction

A spreader and shaft technology, applied in the field of spreaders, can solve the problems of difficulty in meeting the construction schedule, failure to ensure the verticality and high quality of shaft wall components, and achieve fast and reliable installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

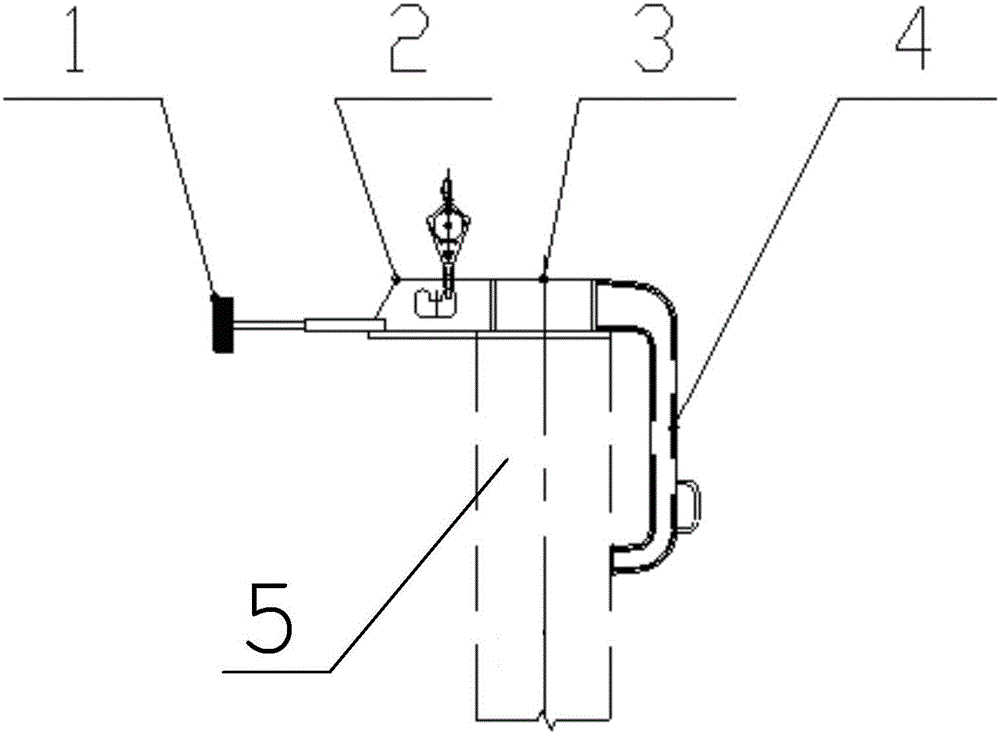

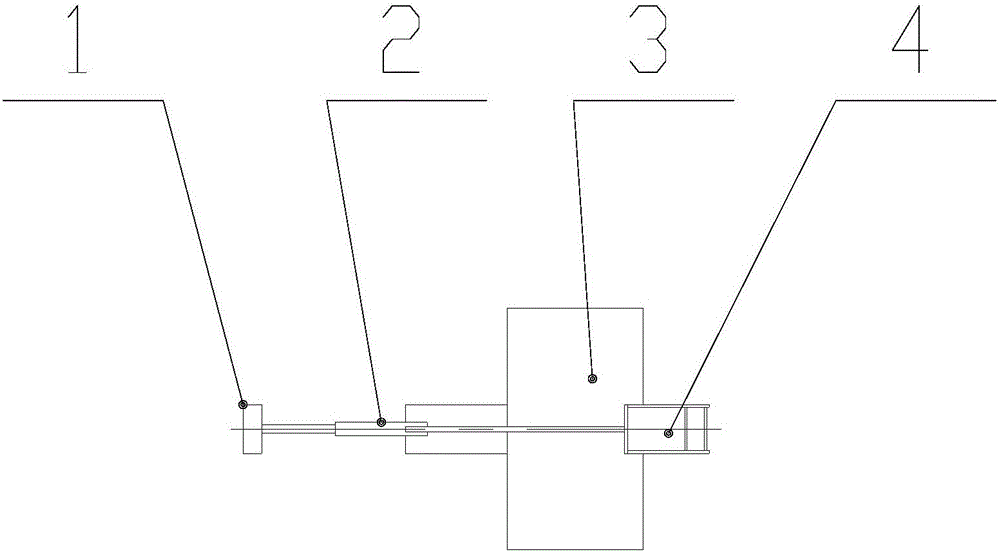

[0011] See attached figure 1 , 2 , a special spreader for shaft construction, which includes: a counterweight 1, a hanging plate 2, and a bottom plate 3;

[0012] The counterweight 1 is connected to the hanging plate 2 through the connecting rod in the inner direction of the shaft wall member 5;

[0013] Hanging plate 2 is used to connect the crane hook;

[0014] The bottom plate 3 is fixedly connected to the hanging plate 2 through the stiffener plate, and connected to the well wall component 5 through the bolts on the upper surface of the well wall component 5 .

[0015] Further, the special spreader for shaft construction also includes: a clamping arm 4; the upper part of the clamping arm 4 is bent and connected to the bottom plate 3 through a reinforcing plate, and the lower part is bent to clamp the outside of the shaft wall member 5.

[0016] Further, the connecting rod connecting the counterweight 1 and the suspension plate 2 is adjustable in length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com