Separation and combination device for realizing material turnover or adding and removing caps and method of use thereof

A material and equipment technology, which is applied in the field of material turnover or adding and removing covers, can solve the problems of complex mechanism and control process, reduce the automatic cooking efficiency of cooking equipment, increase manufacturing costs, etc., and achieve simple control methods, good cleanability, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

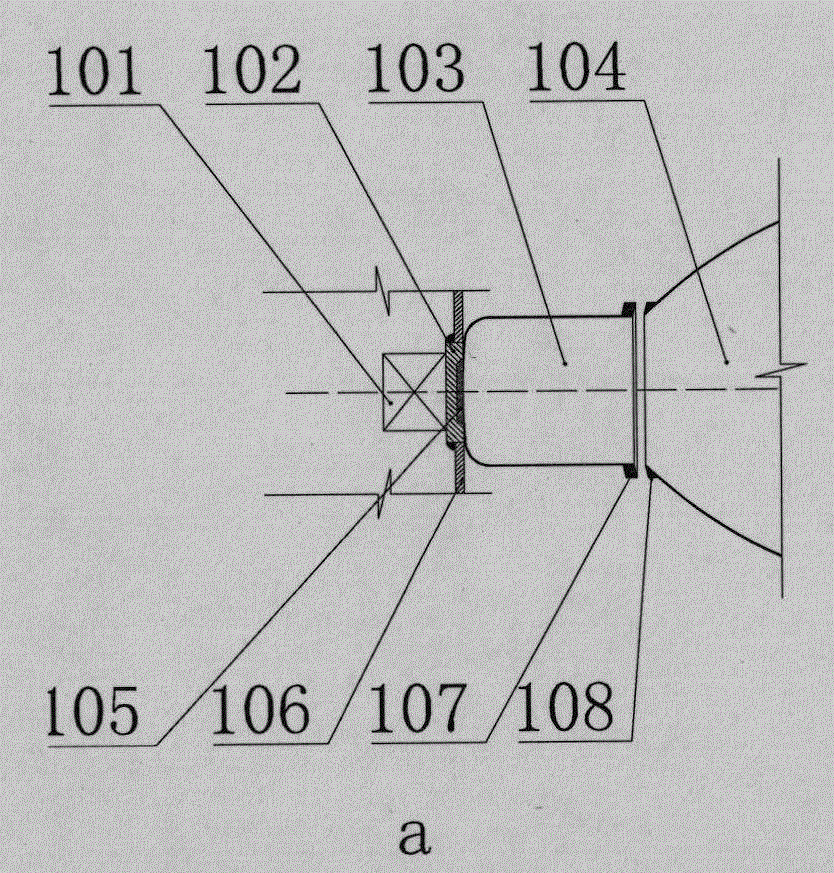

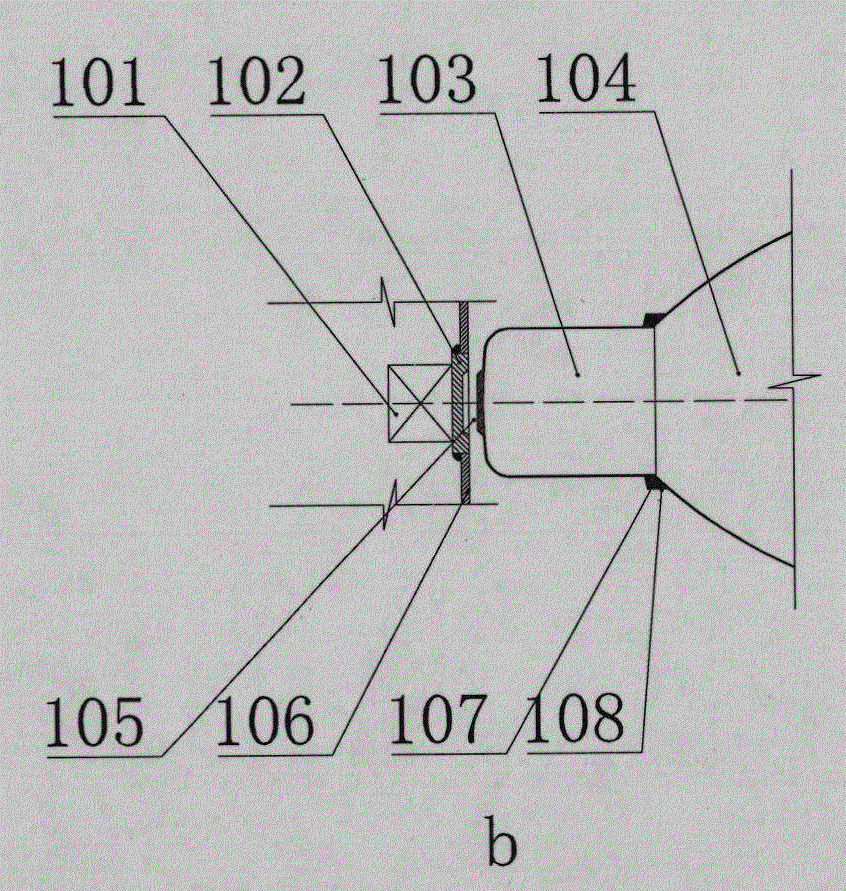

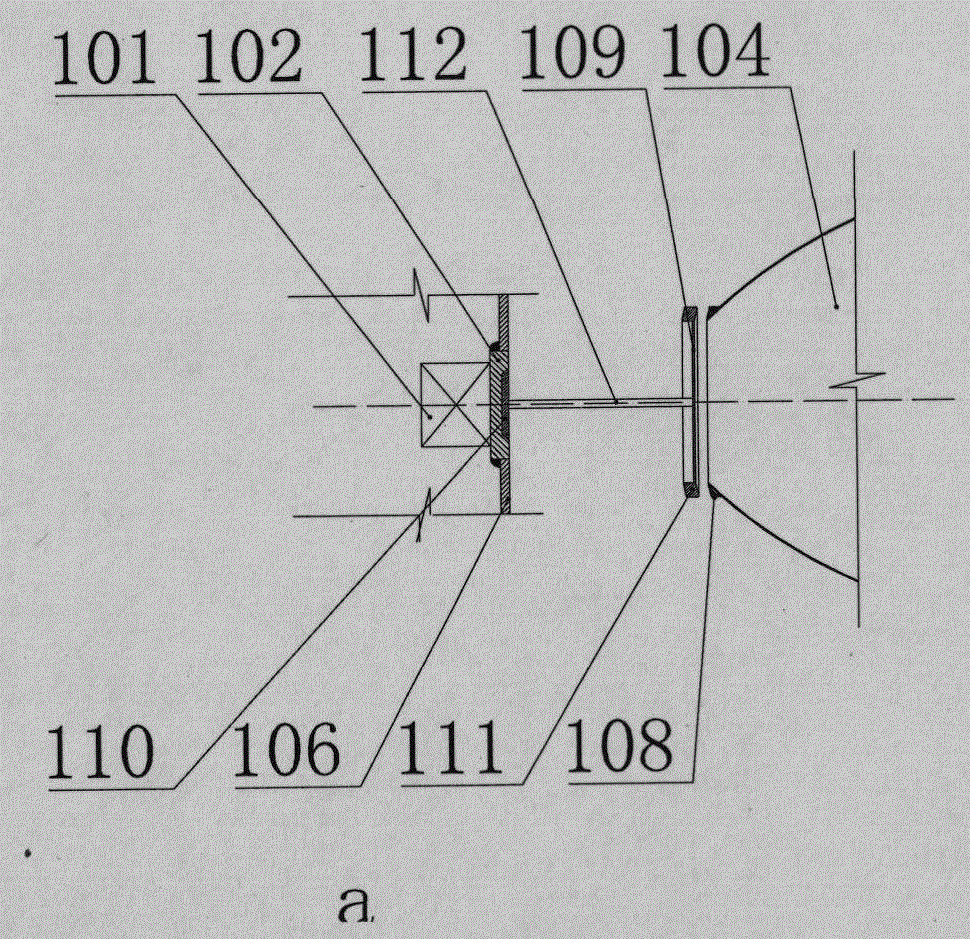

[0055] Figure 1A A schematic diagram showing a combined state of the turnover device and the base of the turnover device in a preferred embodiment when the separation and combination equipment is used for material turnover according to one aspect of the present invention. Referring to FIG. 1 , the separating and combining equipment includes a material container 104 , a turnover device base, a material turnover container 103 , a first moving device (not shown), a first separating and combining device, and a second separating and combining device. Wherein, the turnover device base can be a material turnover container seat specially matched with the material turnover container, or a general modular base compatible with other turnover devices, such as a container cover base. That is to say, the base of the turnover device can be designed as a universal base. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com